Hammer crusher

A hammer crusher and casing technology, which is used in grain processing and other directions, can solve the problems of small crushing ratio, coarse grain size, and increased power consumption, and achieve the effect of simplifying the production process, expanding the application field, and increasing the output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

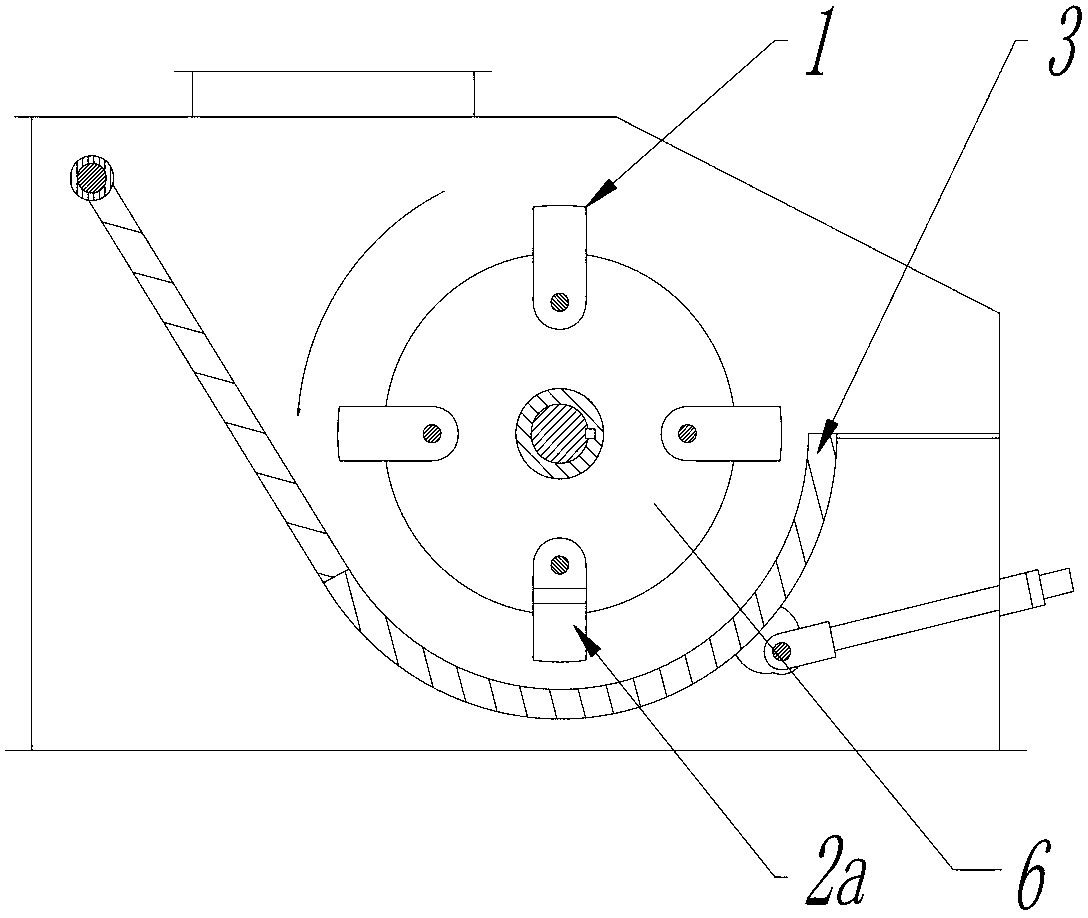

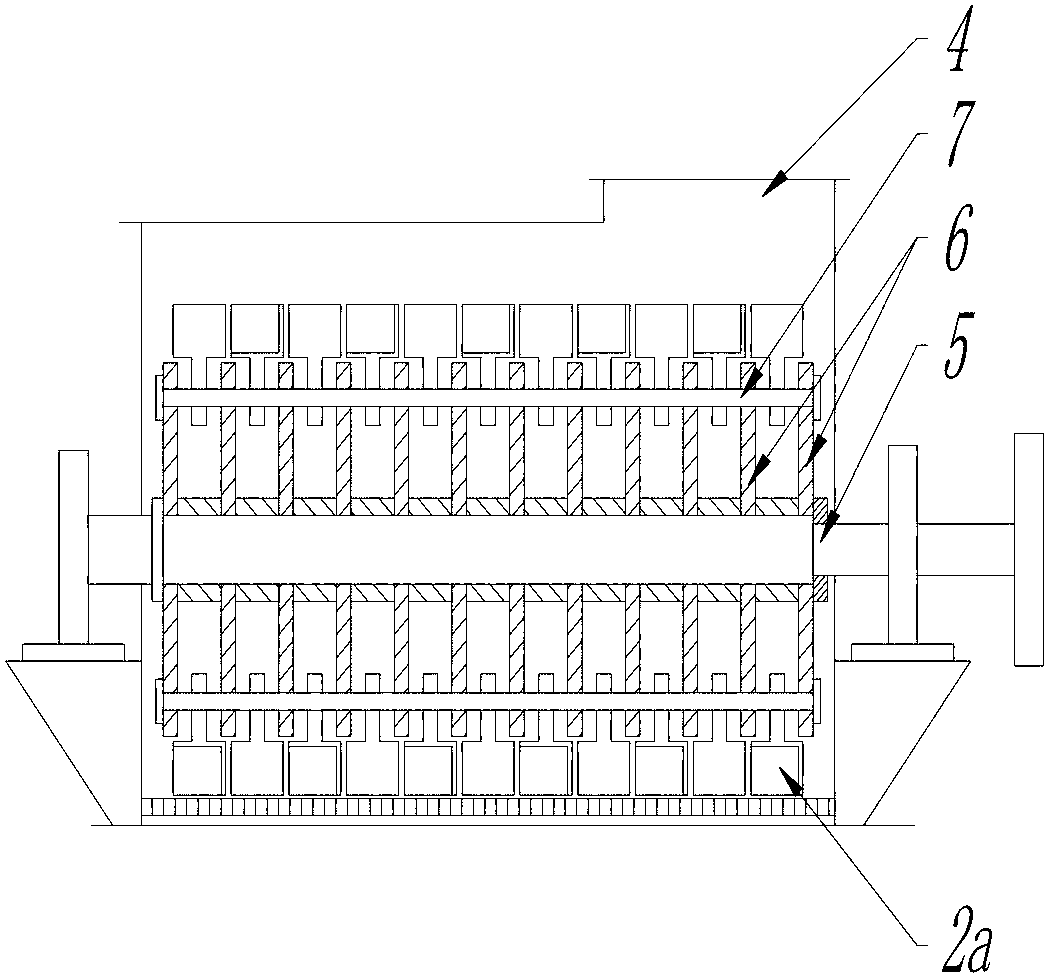

[0049] The core of the present invention is to provide a hammer crusher, which is suitable for crushing products with smaller particle sizes, and when crushing products with smaller particle sizes, increases output and reduces power consumption.

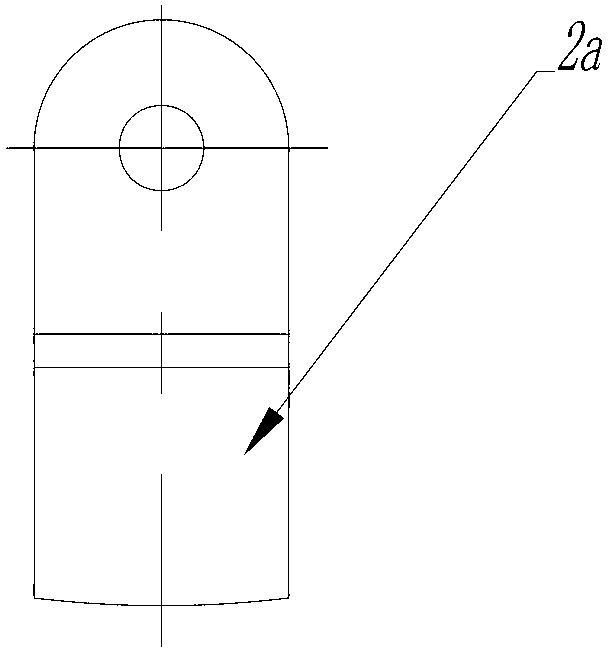

[0050] In order to achieve the above technical effects, the crushed material must be forced to move axially in the crushing cavity, and the qualified particles are continuously discharged from the holes of the screen plate during the moving process. In order to achieve both crushing and forced axial movement of the crushed material, in addition to the normal crushing hammer, a device that can force the material to move axially is also required.

[0051] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com