5mm Coil Leveler

A leveling machine and coil material technology, which is applied in the field of coil leveling machines, can solve the problems of large difference between the same plate, head and tail coils, small steel coils, etc., and achieve the effect of improving the cutting ability and cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

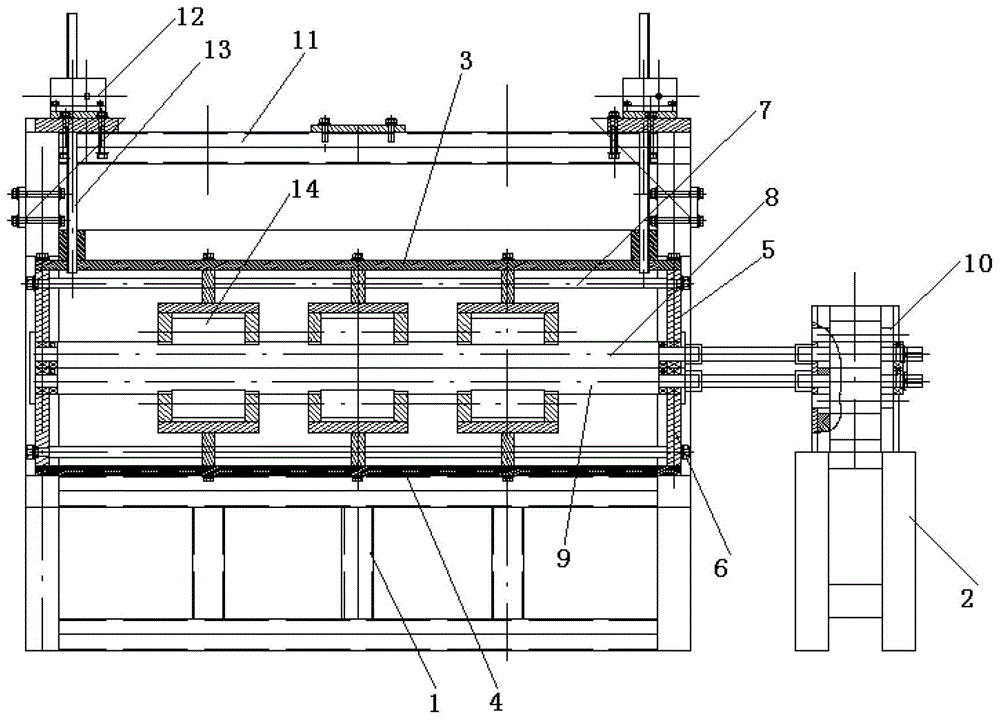

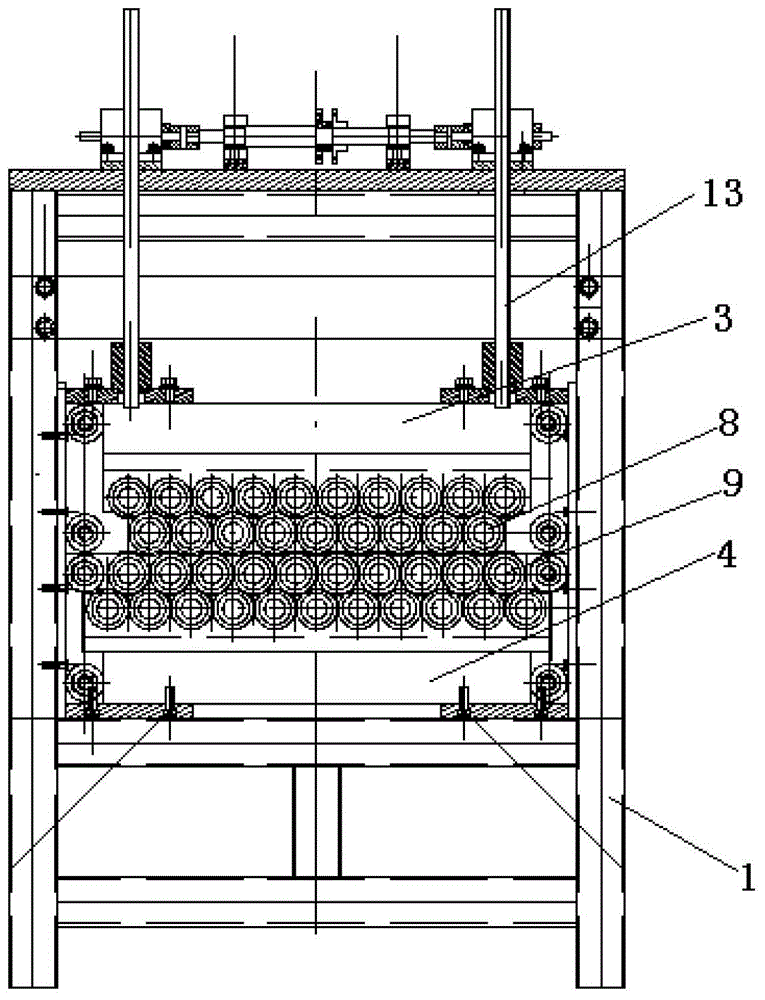

[0012] Referring to the accompanying drawings, the 5 mm coil leveling machine includes a frame support 1, a transmission box support 2, an upper longitudinal pressing plate 3, a lower longitudinal pressing plate 4, an upper longitudinal pressing plate 3 and a lower longitudinal pressing plate are installed on the frame supporting 1. An upper wallboard 5 and a lower wallboard 6 are connected between the two ends of the longitudinal pressure plate 4, tension bolts 7 are respectively connected between the upper wallboard 5 and the lower wallboard 6 on both sides, and the upper wallboard 5 and the lower wallboard 6 There are upper and lower driving rollers 8, 9 installed on the top, and the other ends of the upper and lower driving rollers 8, 9 are connected to the transmission box 10 installed on the transmission box support 2, and a triangular reinforcing plate is arranged above the upper and lower wall panels , the triangular reinforcing plates on both sides are fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com