Framework dewaxing and wax-melting purifying device and framework dewaxing and wax-melting purifying method

A purification device and dewaxing technology, which is applied in the direction of casting molding equipment, molds, cores, etc., can solve the problems of pressure and temperature out of sync, lower mold shell yield, energy waste, etc., to improve quality and yield, Improved purification quality and less energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

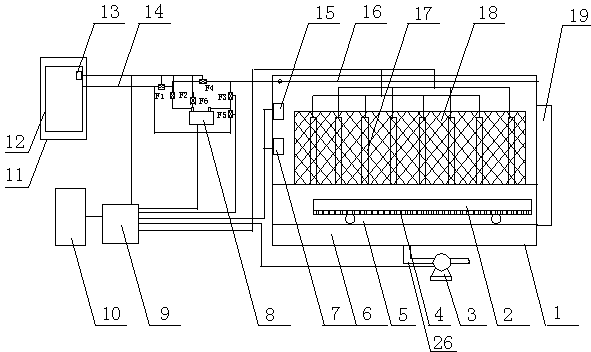

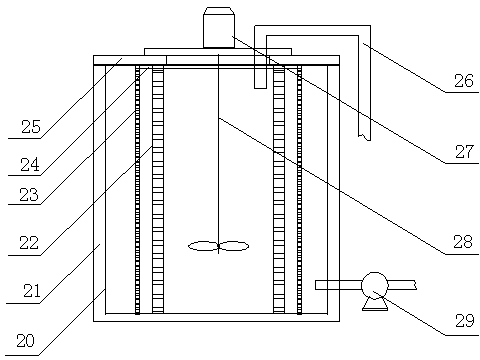

[0033] Such as figure 1 , figure 2 As shown, the mold shell dewaxing and melting wax purification device of the present invention is composed of a dewaxing device and a filtering device, the two are connected through a wax slurry delivery pipe, and a wax slurry pump 3 is arranged on the wax slurry delivery pipe. The dewaxing device includes an electric heating dewaxing furnace, a gas storage tank 12, a pipe network system and a monitoring and control system. The two ends of the pipe network system are respectively connected with the electric heating dewaxing furnace and the gas storage tank 12, and are composed of a booster pump 8, a high-pressure gas pipeline 14 and several electromagnetic control valves F1, F2, F3, F4, F5, and F6 form the air supply pipeline, the pressure relief return pipeline and the air supply pipeline for supplementing air into the air storage tank 12, through the electromagnetic control valves F1, F2, F3, F4, F5, F6 The separate control can realize t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com