Manufacturing process of wood products

A production process and technology for wood products, applied in the field of production that can prevent the cracking of pure solid wood products, can solve problems such as loosening, easy opening of glue, loss of indoor air conditioning effect, etc., to improve environmental protection performance, gentle touch, and conducive to later maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The production process of wood products is as follows:

[0027] 1. The overall shape design of live wood products

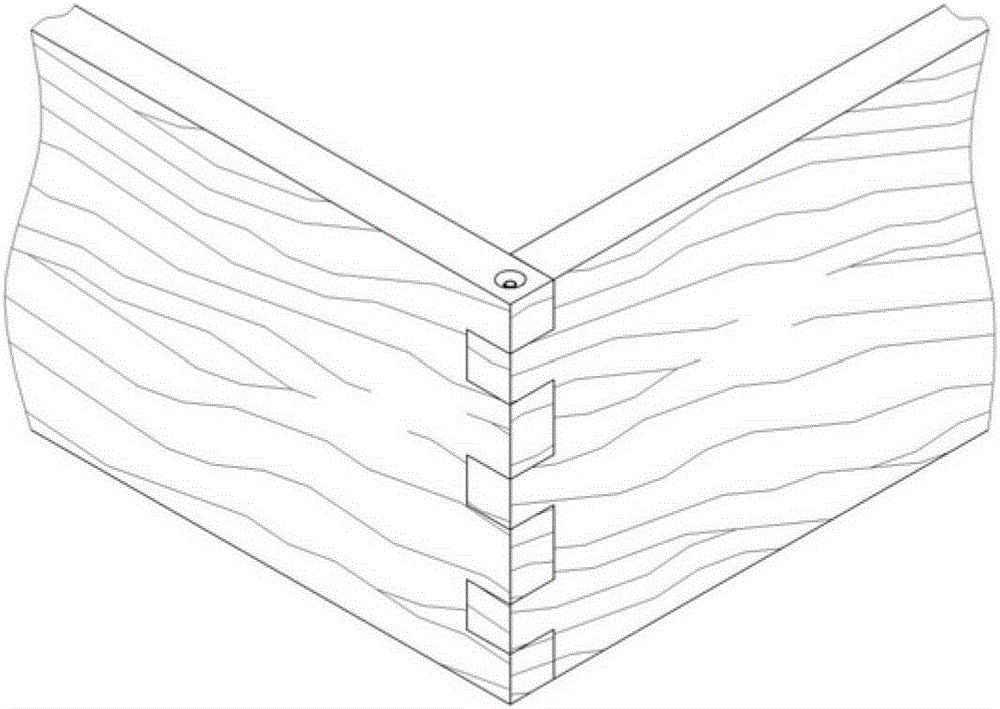

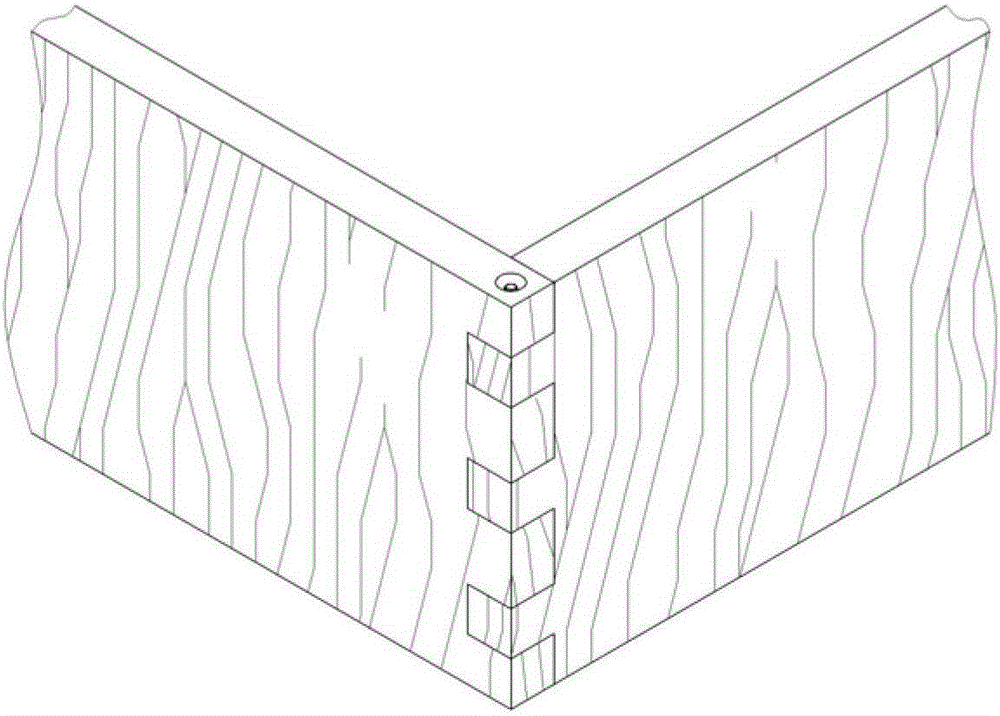

[0028] 2. Process design of active combination

[0029] 3. Shape design of active parts

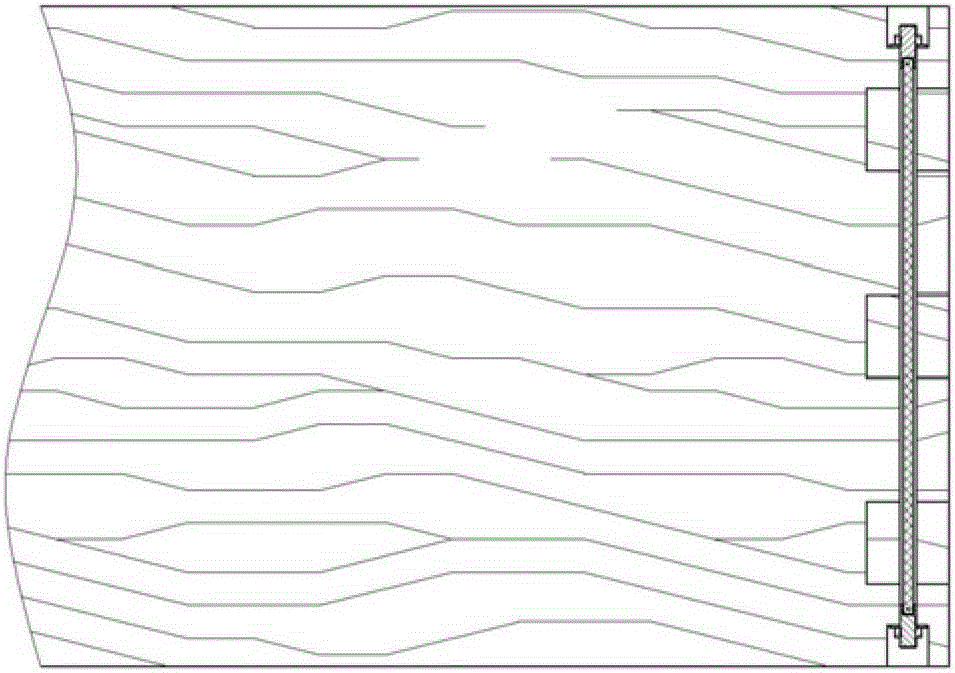

[0030] 4. Position of anti-crack control icon

[0031] 5. Produce parts according to the drawing

[0032] 6. Install anti-crack metal parts

[0033] 7. Overall trial assembly

[0034] 8. Disassemble the parts for grinding

[0035] 9. All fine grinding and trimming

[0036] 10. Apply rubbing wood wax oil (or base color) two to four times

[0037] 11. Fine sand polishing

[0038] 12. Parts combination

[0039] 13. Polishing and waxing

[0040] 14. Packing and leaving the factory

[0041] 15. The user should regularly wipe and maintain it with wood wax when using it.

[0042] The feature of the present invention in the manufacturing process flow is:

[0043] 1. Install elastic fasteners in each single component, and the elastic fasteners are as follows: im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com