Ethylene glycol terephthalate-modified halogen-free flame-retardant polyamide composite material

A technology of ethylene terephthalate and polyethylene terephthalate is applied in the field of halogen-free flame retardant polyamide composite materials, and can solve the problems of high processing requirements and easy moisture absorption.

Inactive Publication Date: 2013-08-21

常熟市弘基无纺制品有限公司

View PDF4 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the strong polarity of the polyamide material, it is easy to absorb moisture, which makes it more demanding in processing and other processes.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

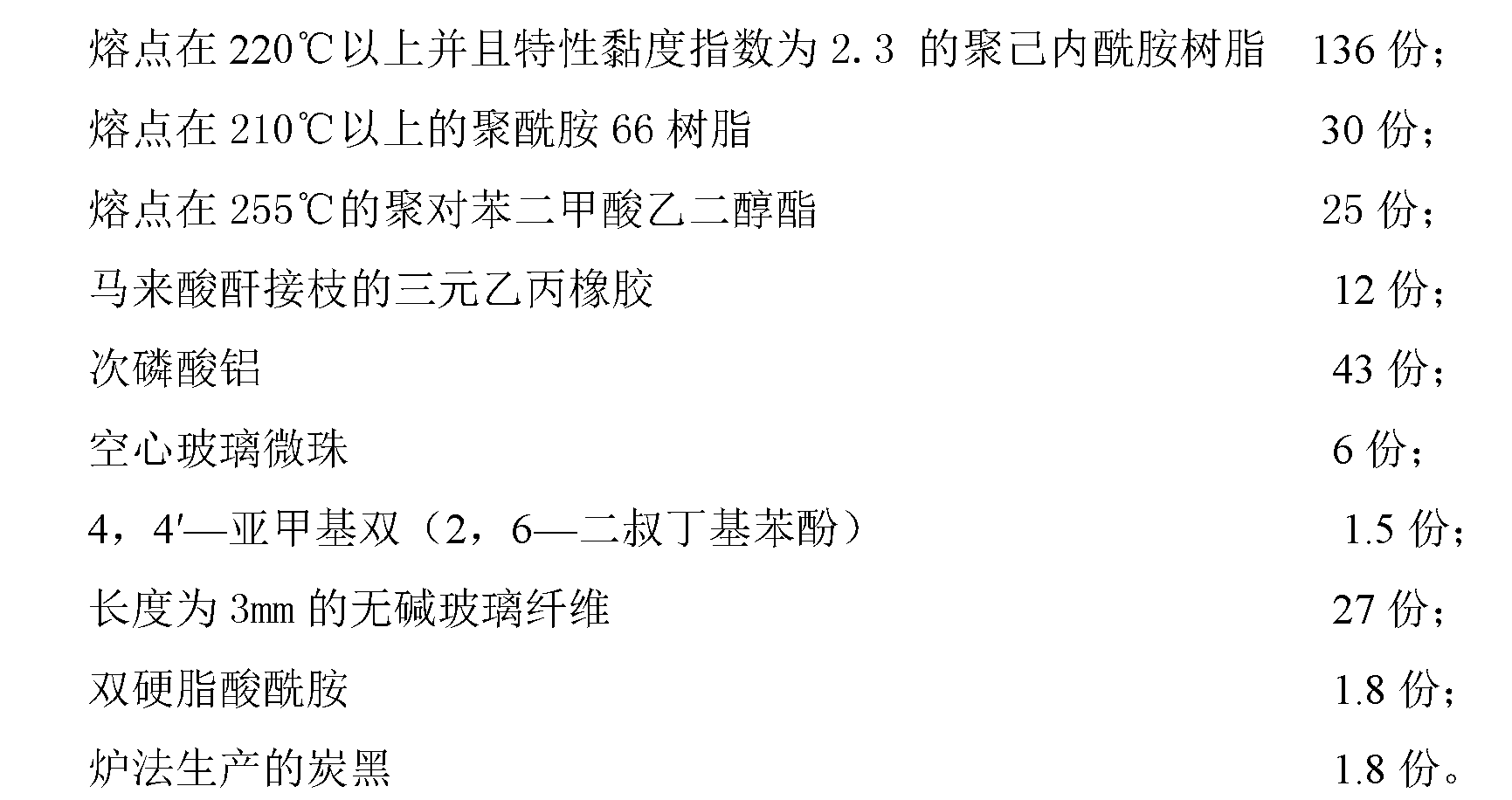

Embodiment 1

[0017]

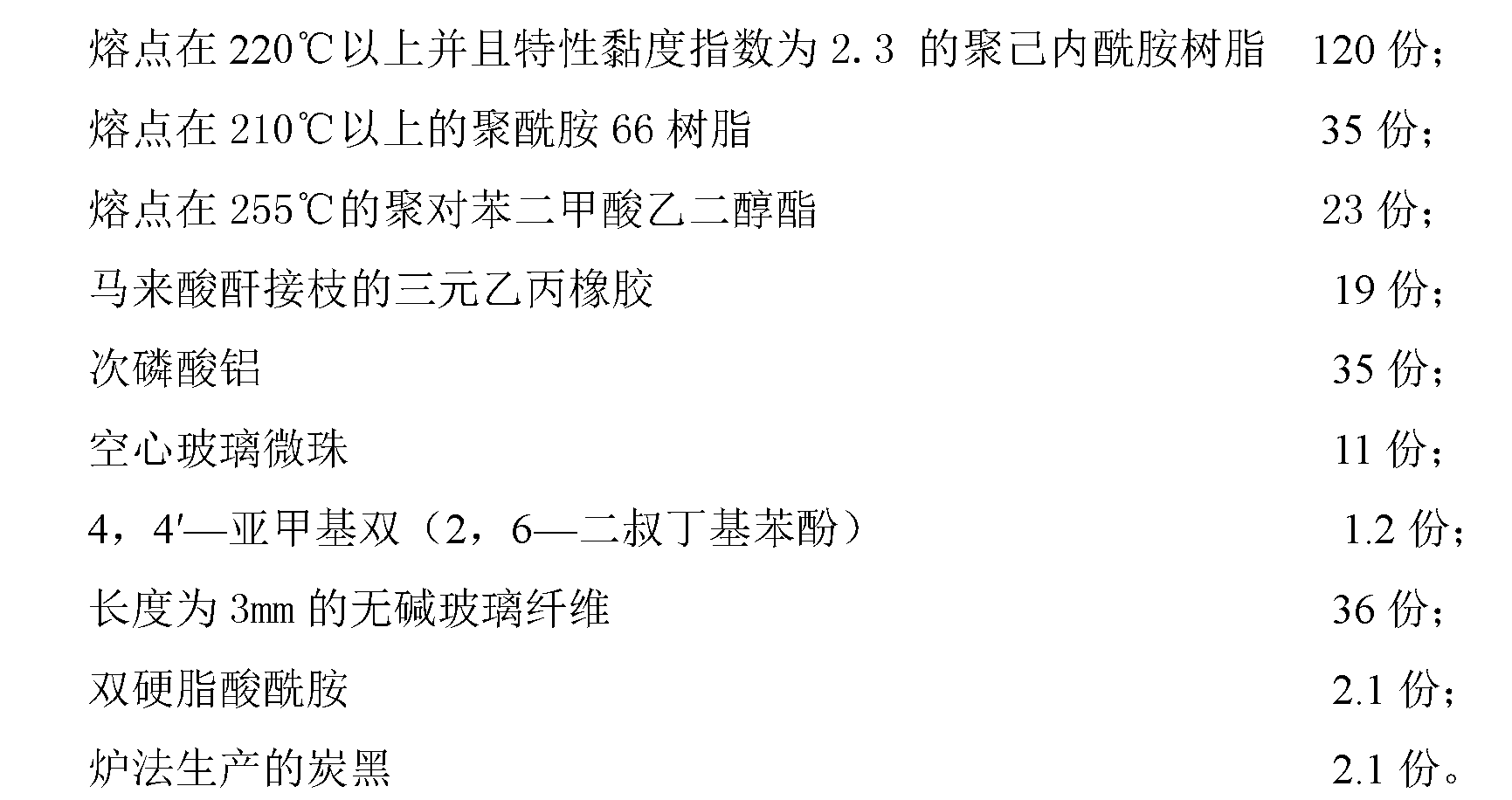

Embodiment 2

[0019]

Embodiment 3

[0021]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

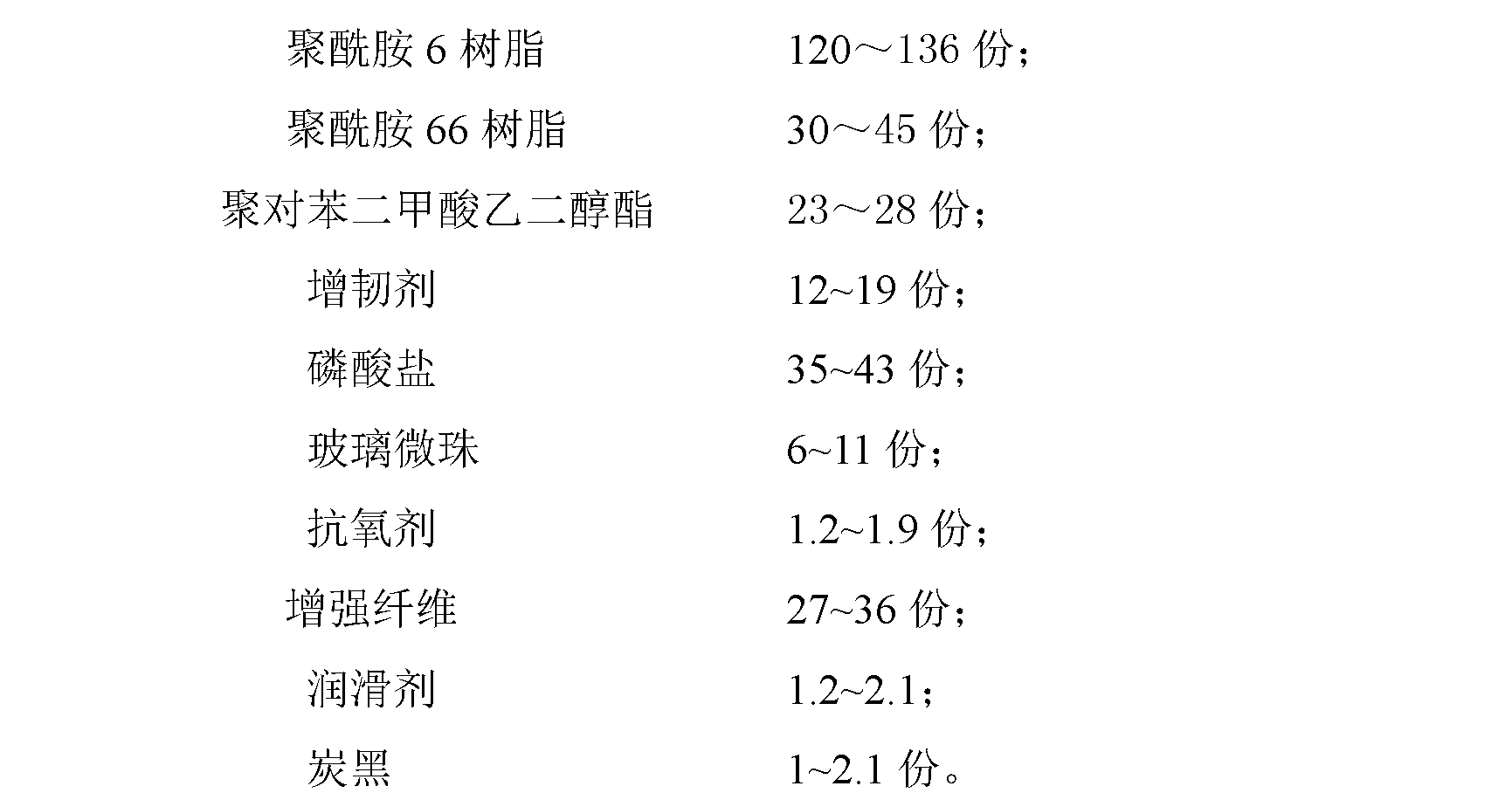

The invention relates to an ethylene glycol terephthalate-modified halogen-free flame-retardant polyamide composite material and belongs to the technical field of macromolecular materials. The ethylene glycol terephthalate-modified halogen-free flame-retardant polyamide composite material is prepared from the following raw materials in parts by weight: 120 to 136 parts of polyamide 6 resin, 30 to 45 parts of polyamide 66 resin, 23 to 28 parts of polyethylene glycol terephthalate, 12 to 19 parts of a flexibilizer, 35 to 43 parts of phosphate, 6 to 11 parts of glass microbeads, 1.2 to 1.9 parts of an antioxidant, 27 to 36 parts of reinforced fiber, 1.2 to 2.1 parts of a lubricating agent and 1 to 2.1 parts of carbon black. According to a test, the polyethylene glycol terephthalate-modified halogen-free flame-retardant polyamide composite material provided by the invention has the following performance indexes: the tensile strength is 135-158 MPa; the bending strength is 226-247 MPa; the bending modulus is 3,800-4,700 MPa; the notch impact strength is 12.4-15.2 kj / m<2>; and the flame resistance reaches V-0(UL-94-1.5mm).

Description

technical field [0001] The invention belongs to the technical field of polymer materials, and in particular relates to a halogen-free flame-retardant polyamide composite material modified by ethylene terephthalate. Background technique [0002] Polyamide is the most widely used engineering plastic material, widely used in automobiles, electrical appliances, construction and other fields. However, due to the strong polarity of the polyamide material, it is easy to absorb moisture, which makes it more demanding in processing and other processes. Polyethylene terephthalate has strong crystallinity, high melting point, and good strength. It is often used in the alloying of some engineering plastic materials to meet the requirements of engineering plastic materials in special fields such as temperature resistance and solvent resistance. The technical solution to be introduced below is based on this premise. Contents of the invention [0003] The task of the present invention ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L77/02C08L77/06C08L67/02C08K13/04C08K7/28C08K3/32C08K3/04C08K7/14

Inventor 李梅新

Owner 常熟市弘基无纺制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com