Colored polyurethane paint having elastic handfeel and used for spraying and preparation method as well as application thereof

A polyurethane elastic and hand-feeling paint technology, which is applied in the direction of polyester coatings and coatings, can solve the problems of inelastic hand feel, etc., and achieve the effects of good transparency, excellent color, and good touch elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

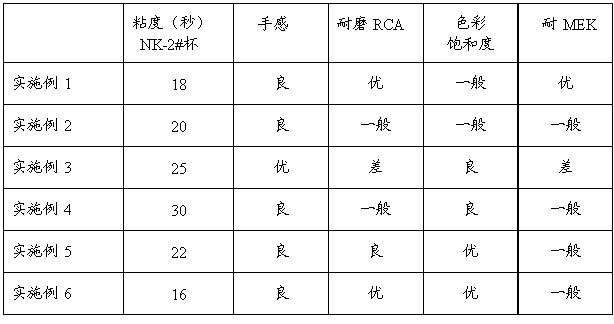

Examples

Embodiment 1

[0070] The described spraying of embodiment 1 uses color polyurethane elastic feel paint coating, wherein, its weight percentage consists of:

[0071] 27.5 parts of high hydroxyl value saturated polyester resin;

[0072] 12.5 parts of low hydroxyl value saturated polyester resin;

[0073] 32 parts of butyl acetate;

[0074] 19.4 parts of xylene;

[0075] Dumb powder 6.5 parts;

[0076] Leveling agent 0.5 part;

[0077] Drier 0.1 part;

[0078] Nano color paste 1.5 parts.

[0079] The preparation method of the described spraying of embodiment 1 is as follows with colored polyurethane elastic feel paint coating:

[0080] Take 27.5 parts (weight) of saturated polyester resin with high hydroxyl value, the hydroxyl value is 130 mg KOH / g, 12.5 parts (weight) of saturated polyester resin with low hydroxyl value, the hydroxyl value is 50 mg KOH / g, and then add leveling agent 0.5 parts (weight), wherein the leveling agent is BYK-333 type siloxane, after the formed mi...

Embodiment 2

[0081] The described spraying of embodiment 2 uses colored polyurethane elastic feel paint coating, wherein, its weight percentage consists of:

[0082] 20.5 parts of high hydroxyl value saturated polyester resin;

[0083] 19.5 parts of low hydroxyl value saturated polyester resin;

[0084] 28.5 parts of butyl acetate;

[0085] 20.9 parts of xylene;

[0086] Dumb powder 6.5 parts;

[0087] Leveling agent 0.5 part;

[0088] Drier 0.1 part;

[0089] Nano color paste 3.5 parts.

[0090] The preparation method of the described spraying of embodiment 2 is as follows with colored polyurethane elastic feel paint coating:

[0091] Take 20.5 parts (weight) of saturated polyester resin with a high hydroxyl value and a hydroxyl value of 130 mg KOH / g, 19.5 parts (weight) of a saturated polyester resin with a low hydroxyl value and a hydroxyl value of 50 mg KOH / g, and then add a leveling agent 0.5 parts (by weight), of which the leveling agent is BYK-333 type siloxane. A...

Embodiment 3

[0092] The described spraying of embodiment 3 uses colored polyurethane elastic feel paint coating, wherein, its weight percentage consists of:

[0093] 27.5 parts of high hydroxyl value saturated polyester resin;

[0094] 12.5 parts of low hydroxyl value saturated polyester resin;

[0095] 20 parts of butyl acetate;

[0096] 27.4 parts of xylene;

[0097] Dumb powder 6.5 parts;

[0098] Leveling agent 0.5 part;

[0099] Drier 0.1 part;

[0100] Nano color paste 5.5 parts.

[0101] The preparation method of the described spraying of embodiment 3 is as follows with colored polyurethane elastic feel paint coating:

[0102] Take 27.5 parts (weight) of saturated polyester resin with high hydroxyl value, the hydroxyl value is 130 mg KOH / g, 12.5 parts (weight) of saturated polyester resin with low hydroxyl value, the hydroxyl value is 50 mg KOH / g, and then add leveling agent 0.5 parts (weight), of which the leveling agent is BYK-333 type siloxane. After the formed mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com