Small-size 600MPa-level aseimatic twisted steel and manufacturing method thereof

A technology of threaded steel bar and manufacturing method, which is applied in the field of iron and steel metallurgy and steel rolling, and can solve the problems of unfavorable seismic performance of small-sized threaded steel bars, reduced strength-to-yield ratio, and unsatisfactory seismic performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

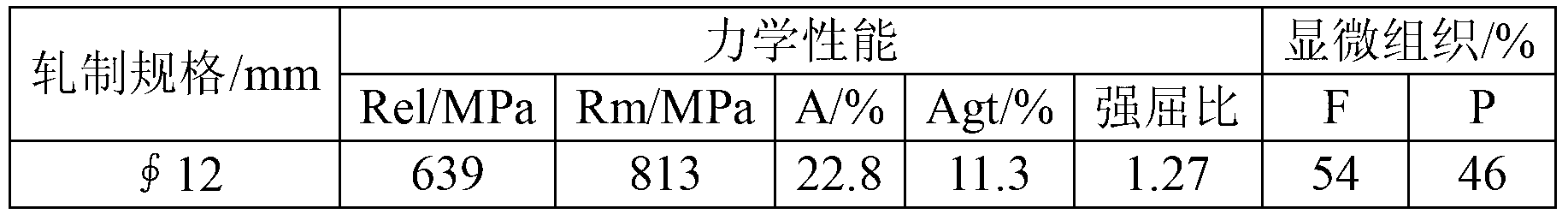

[0025] Using converter smelting, adding VN (V78N15) alloy at the argon blowing station, and then continuous casting into 150mm×150mm billets; the heating temperature of the soaking section in the heating furnace is 1220℃; the continuous bar and wire rolling mill is used for rolling and rolling The specification is ∮12mm, the open-rolling temperature is 1100°C, and the final rolling temperature is 1020°C; it adopts four-cut rolling, without water penetration after rolling, the temperature of the cooling bed on the rolling piece is 950°C, and the cooling bed is naturally cooled to room temperature. That is, 600MPa-level seismic rebar is obtained. The chemical composition of the steel bar is: C0.24wt%, Si0.70wt%, Mn1.10wt%, V0.128wt%, Cr0.56wt%, Ti0.02wt%, N200ppm. Table 1 shows the mechanical properties, yield strength> 620MPa, tensile strength> 750MPa, the elongation after breaking>14%, the total elongation at maximum force>9%, the strength to yield ratio>1.25.

[0026] Table 1 T...

Embodiment 2

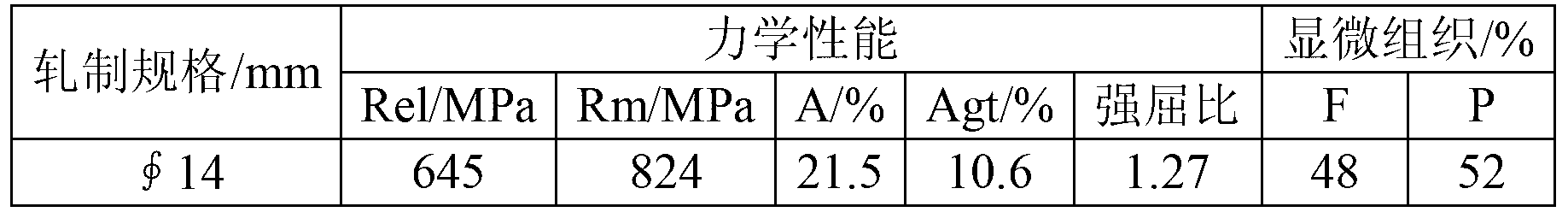

[0029] Using converter smelting, adding VN (V78N15) alloy at the argon blowing station, and then continuous casting into 150mm×150mm billets; the heating temperature of the soaking section in the heating furnace is 1210℃; the continuous bar and wire rolling mill is used for rolling and rolling The specification is ∮14mm, the opening rolling temperature is 1080°C, and the final rolling temperature is 1000°C; adopts three-cut rolling, no water is penetrated after rolling, the temperature of the cooling bed on the rolling piece is 960°C, and it is naturally cooled to room temperature on the cooling bed. Obtained 600MPa earthquake-resistant rebar. The chemical composition of the steel bar is: C0.25wt%, Si0.65wt%, Mn1.05wt%, V0.136wt%, Cr0.57wt%, N210ppm. Table 2 shows the mechanical properties, yield strength> 620MPa, tensile strength> 750MPa, the elongation after breaking>14%, the total elongation at maximum force>9%, the strength to yield ratio>1.25.

[0030] Table 2 The mechanica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com