A dry strength agent for papermaking and its preparation and application method

A technology of dry strength agent and alcohol solvent, which is applied in the direction of strengthening agent addition, etc., can solve the problems of high water retention value, paper is easy to break, and large amount of dry strength agent is used, so as to improve the tensile strength, increase the tensile strength, and fine paper texture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

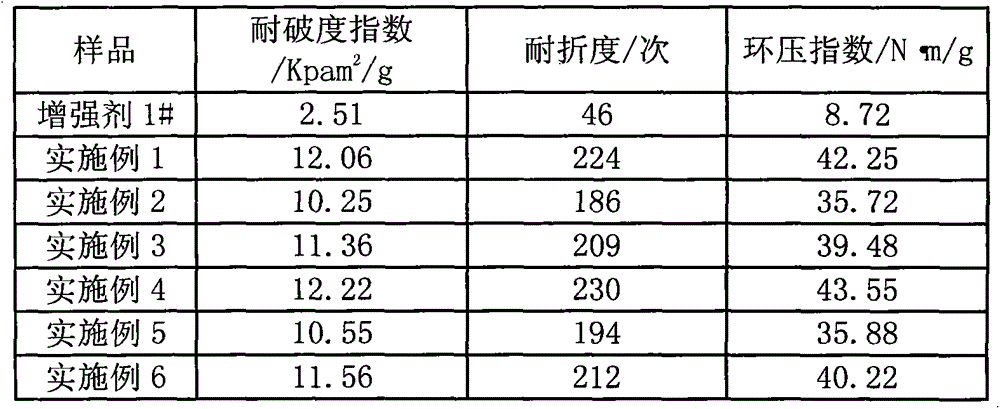

Examples

Embodiment 1

[0026] Weigh 430kg of cornstarch and 250kg of etherification agent sodium chloroacetate and mix them evenly, put them into the mixer, then add 50kg of soda ash to the mixer, stir for 25min, then add 200kg of caustic soda, react for 30min, add 80kg of ethanol, and the temperature rises to 45 ℃, reacted for 2 hours, dried at 85 ℃, and pulverized to obtain a white powder which is a dry strength agent for papermaking.

Embodiment 2

[0028] Weigh 550kg of cornstarch and 275kg of etherification agent sodium chloroacetate, mix them evenly, put them into the mixer, then add 80kg of soda ash to the mixer, stir for 40min, then add 225kg of caustic soda, react for 45min, add methanol 100kg, and the temperature rises to 55 ℃, reacted for 3 hours, dried at 95 ℃, and pulverized to obtain a white powder which is a dry strength agent for papermaking.

Embodiment 3

[0030] Weigh 650kg of cornstarch and 300kg of etherification agent sodium chloroacetate and mix them evenly, put them into the agitator, then add 100kg of soda ash to the agitator, stir for 60min, then add 250kg of caustic soda, react for 60min, add 110kg of isopropanol, and the temperature rises to 65°C, react for 4 hours, dry and pulverize at 105°C to obtain a white powder which is a dry strength agent for papermaking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com