Manufacturing technology of plant stem, hull, particle concrete masonry block and wallboard

A plant stem and wall-building technology, which is applied in the field of wall building materials, shells, granular concrete blocks and wall panels, and plant stems, can solve the problems of complex construction technology, heavy wall weight, and long construction period, and achieve Huge economic and social benefits, low cost and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

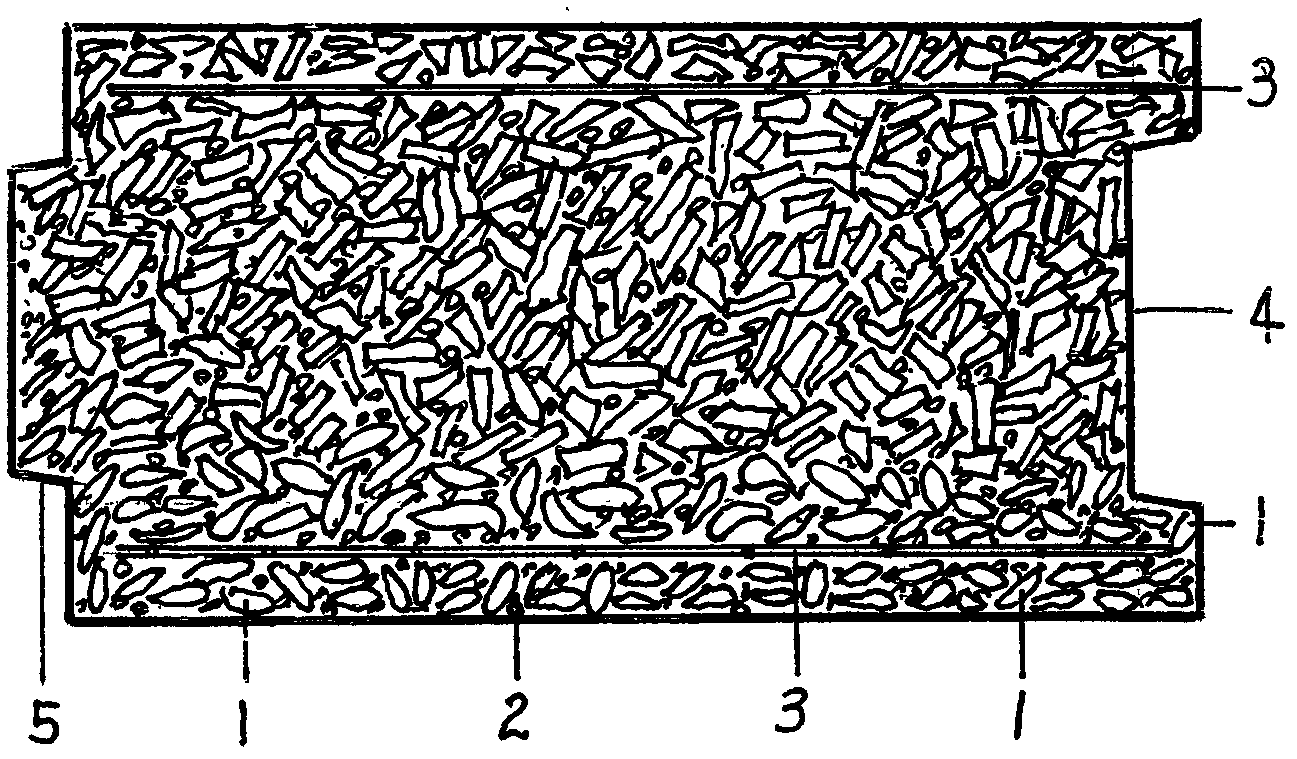

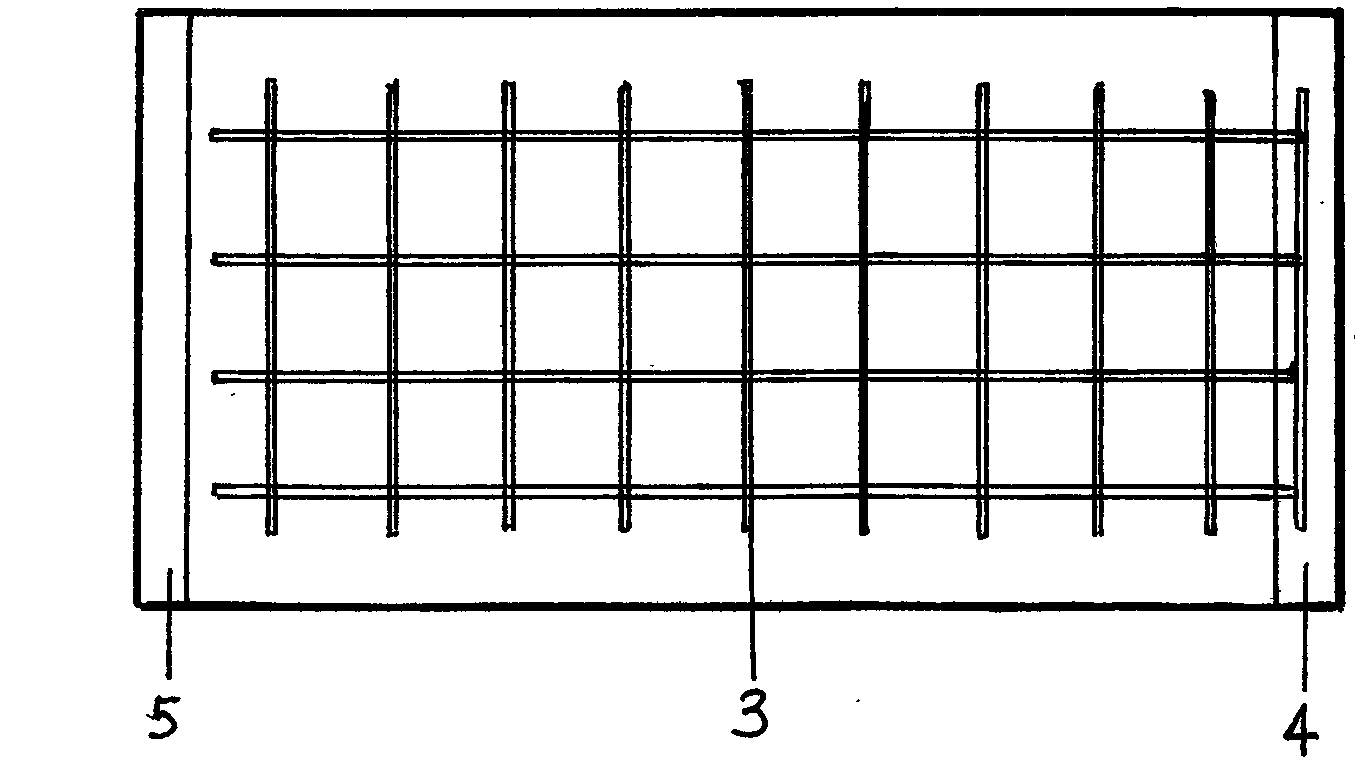

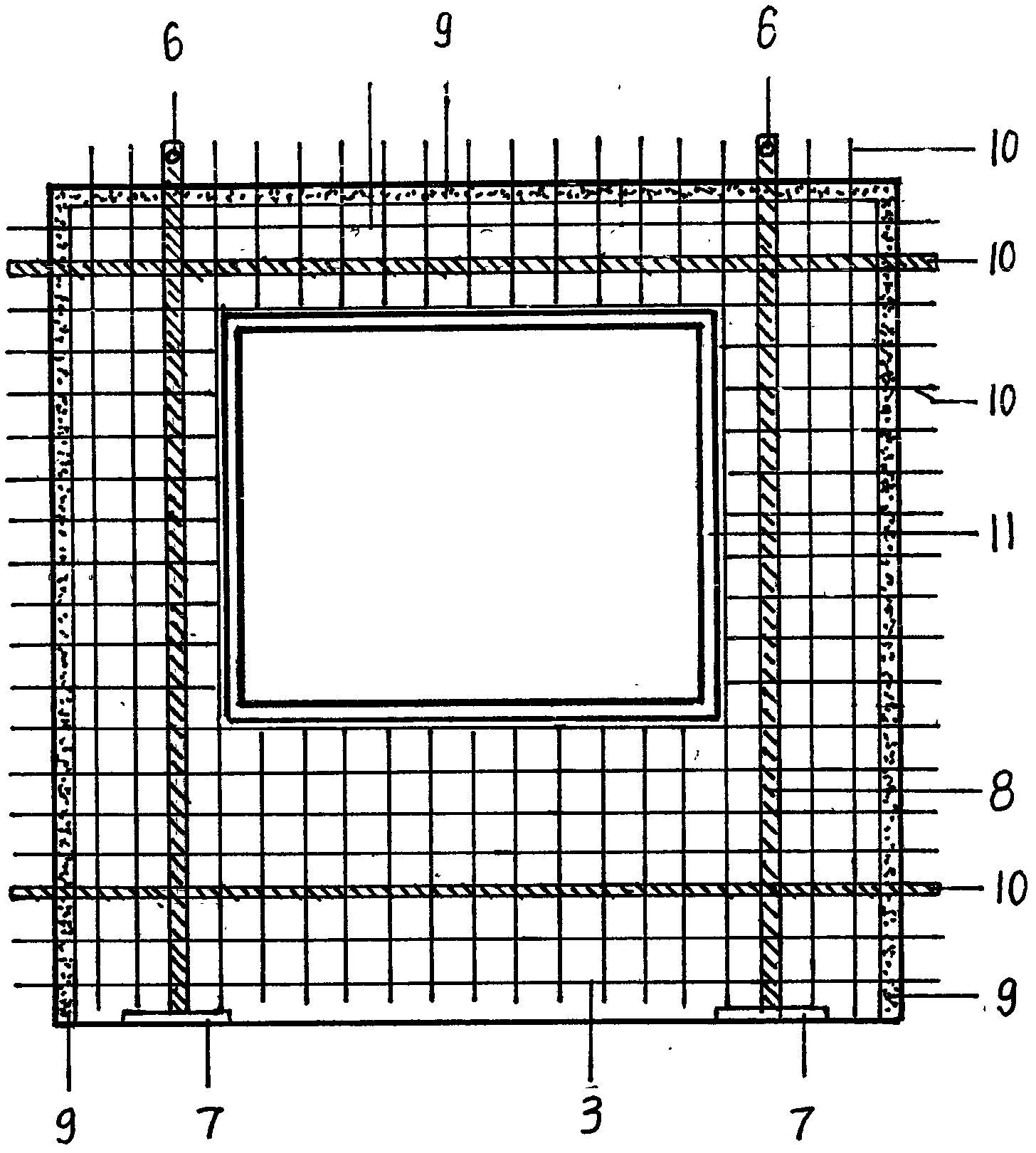

[0018] Below in conjunction with accompanying drawing the embodiment of the technical solution of the present invention is described in detail

[0019] In order to overcome the defects existing in the existing technology of building walls with small hollow sintered bricks, the present invention proposes a manufacturing technology for plant stems, shells, granular concrete blocks and wallboards, which share the same The necessary technical features: all are the basic materials of building walls, and the plant stems, shells, granular concrete blocks and wall panels of the present invention are characterized in that they are dried after being soaked in cooked glutinous rice juice with alum Lightweight granular aggregates of plant stems and shells and lightweight high-strength blocks and lightweight high-strength prefabricated wallboards made of adhesives,

[0020] The plant stem and shell lightweight granular aggregate made after soaking glutinous rice juice with alum and drying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com