Integrated grounding piezoelectric fuze

A fuze and piezoelectric technology, applied in the field of sensors, can solve the problems of increasing unreliable factors, poor contact of connectors, failure of connector springs, etc., and achieve the effect of light weight, simple structure and elimination of interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

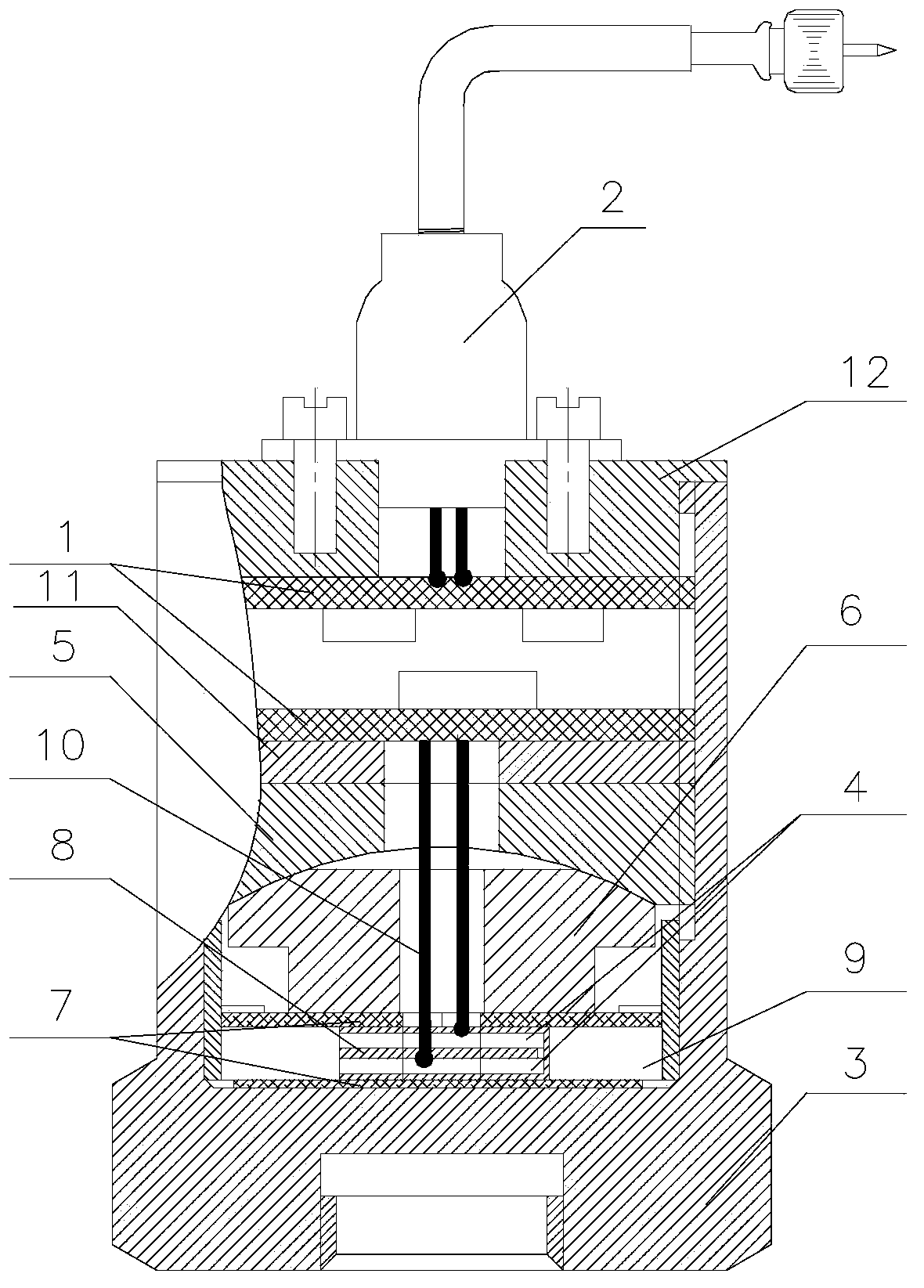

[0029] Such as figure 1 Shown is the cross-sectional view of the structure of the integrated piezoelectric fuze of the present invention. The high-impact integrated ground-contacting piezoelectric fuze of the present invention includes a signal processing circuit module 1, a signal output assembly 2, a housing 3, a piezoelectric sheet 4, a preset Tight ring 5, inertial mass block 6, insulating sheet 7, lead sheet 8, positioning ring 9, lead wire 10, pressure ring 11 and upper cover 12, wherein the piezoelectric sheet 4 is a piezoelectric ceramic sheet.

[0030] The signal processing circuit module 1 is potted inside the casing 3 with an insulating and damping material, placed above the pressure ring 11, and the insulating and damping material can be silicon rubber. The preload ring 5 is located between the pressure ring 11 and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com