Drop test machine

A testing machine and testing point technology, used in impact testing, machine/structural component testing, electrical measurement, etc., can solve the problems of time-consuming and labor-intensive operation, low general accuracy, etc., and achieve the effect of high efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

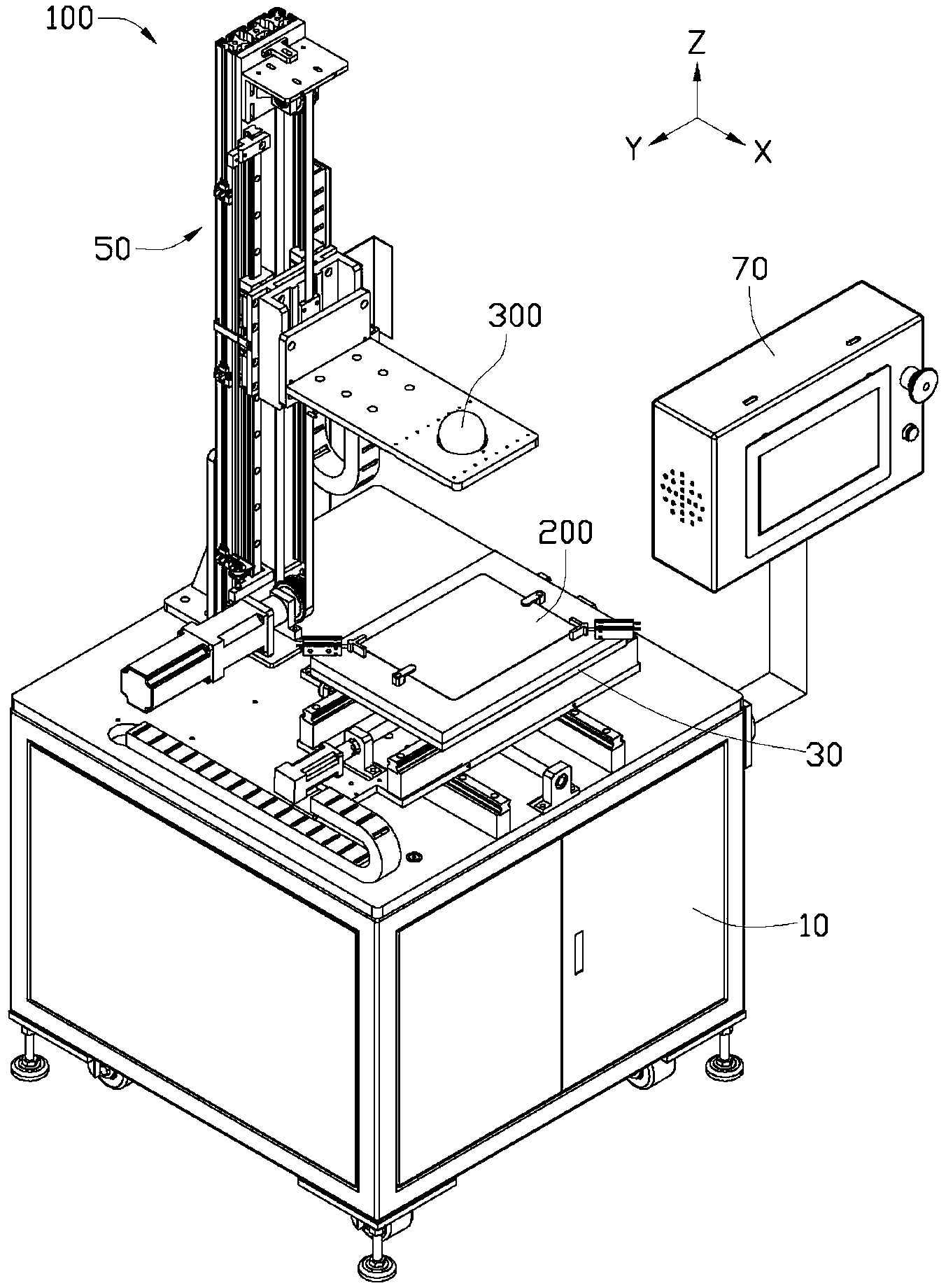

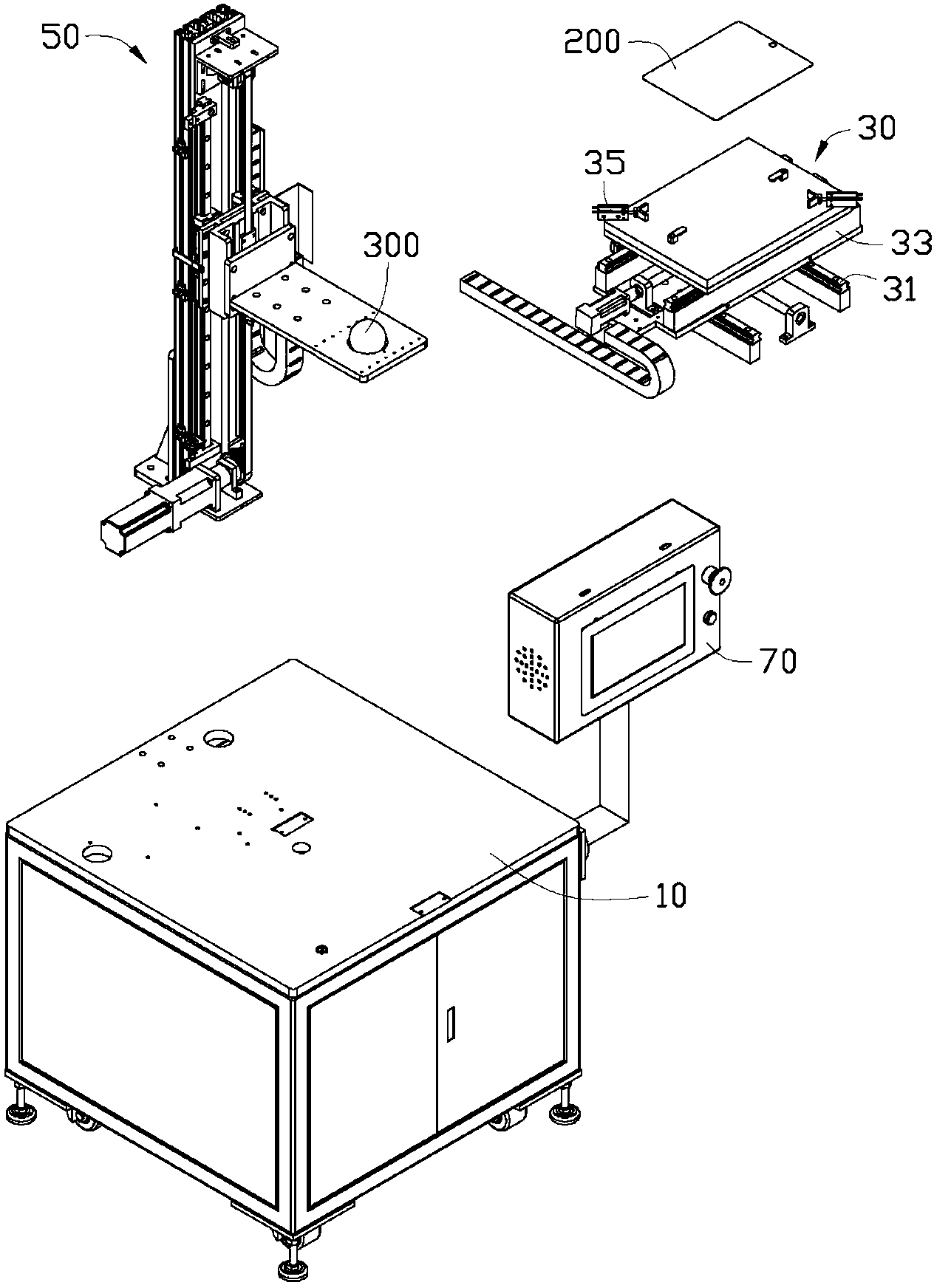

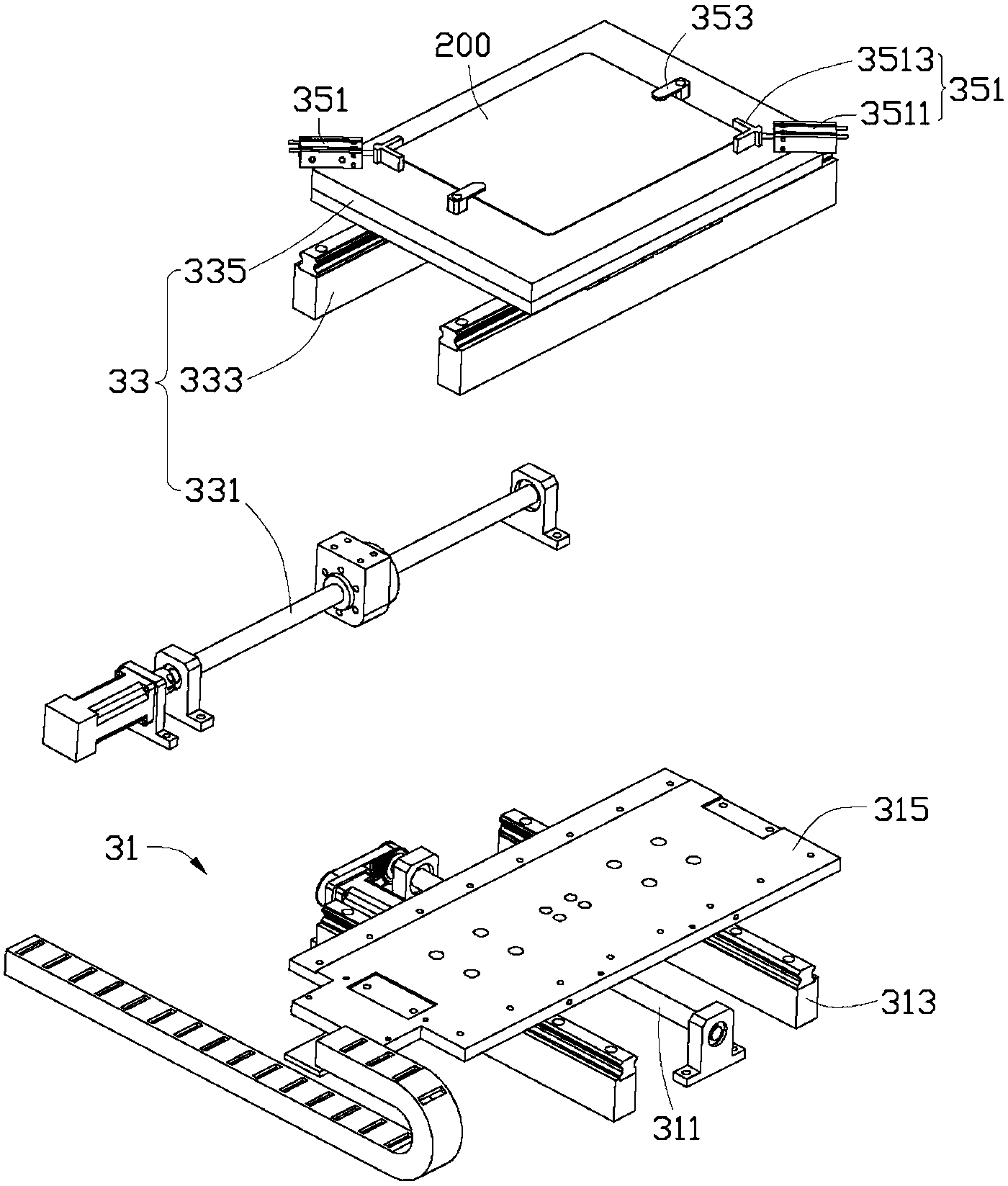

[0016] see figure 1 and figure 2 , the drop testing machine 100 of the preferred embodiment of the present invention includes an electric control box 10 , a bearing assembly 30 , a ball dropping device 50 and a control device 70 . The electric control box 10 carries and is electrically connected to the bearing assembly 30 , the ball dropping device 50 and the control device 70 , and under the control of the control device 70 adjusts the vertical height of the ball dropping device 50 and the height of the bearing assembly 30 . The horizontal position of the object to be tested 200 enables the impact ball 300 with a certain weight to fall freely through the ball drop device 50 and hit each test point of the object to be tested 200 in turn, thereby applying a predetermined impact force to each test point to perform the test. Impact resistance test. In this embodiment, the object under test 200 is an electronic product, and the impact ball 300 is generally a shot ball.

[0017...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com