Reel-to-reel manufacturing method for cadmium sulfide buffering layer

A cadmium sulfide and buffer layer technology, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, electrical components, etc., can solve problems such as large difference in band gap, increase in defect states, and low conversion efficiency of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments of the present invention will be described in more detail below in conjunction with the accompanying drawings.

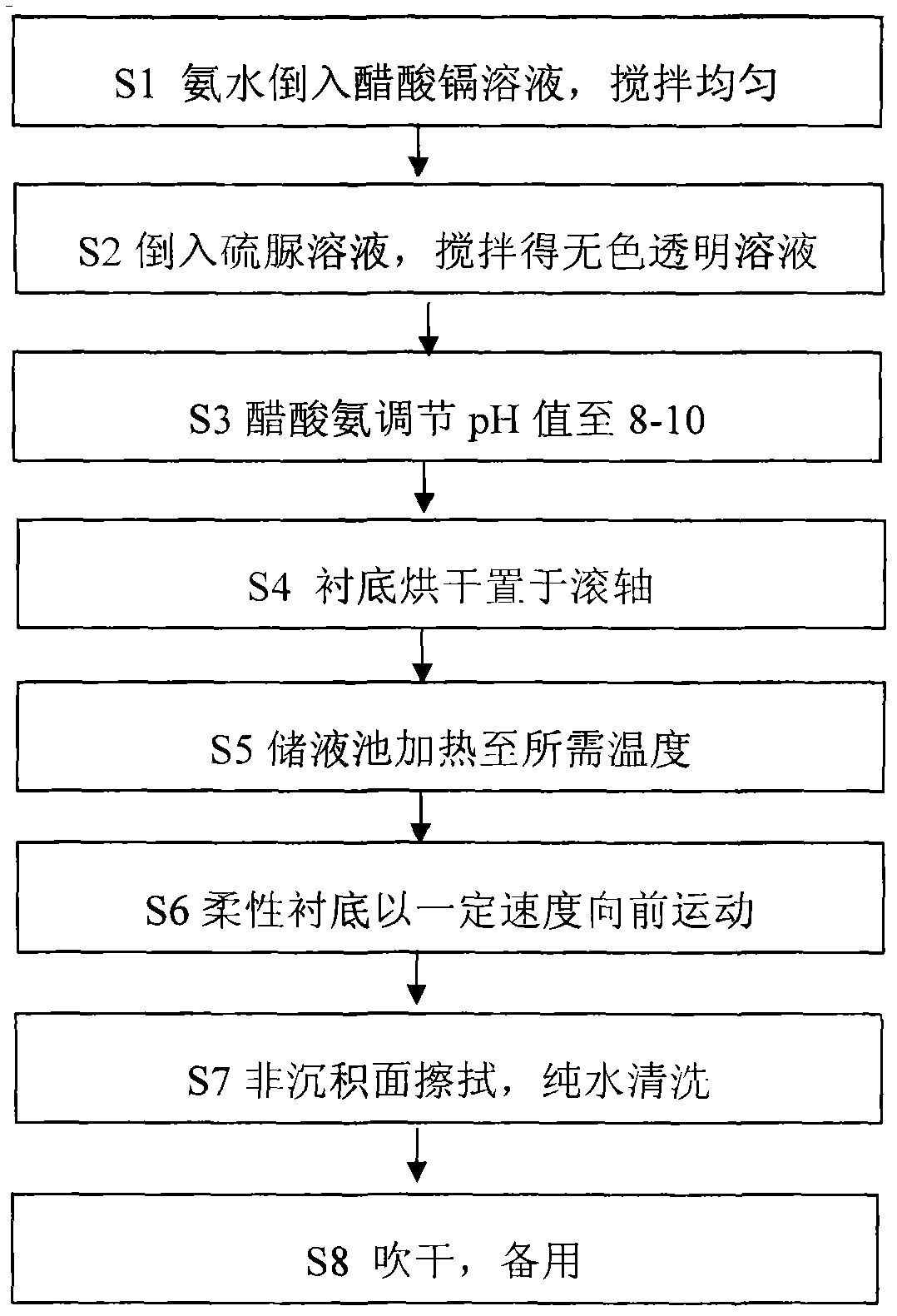

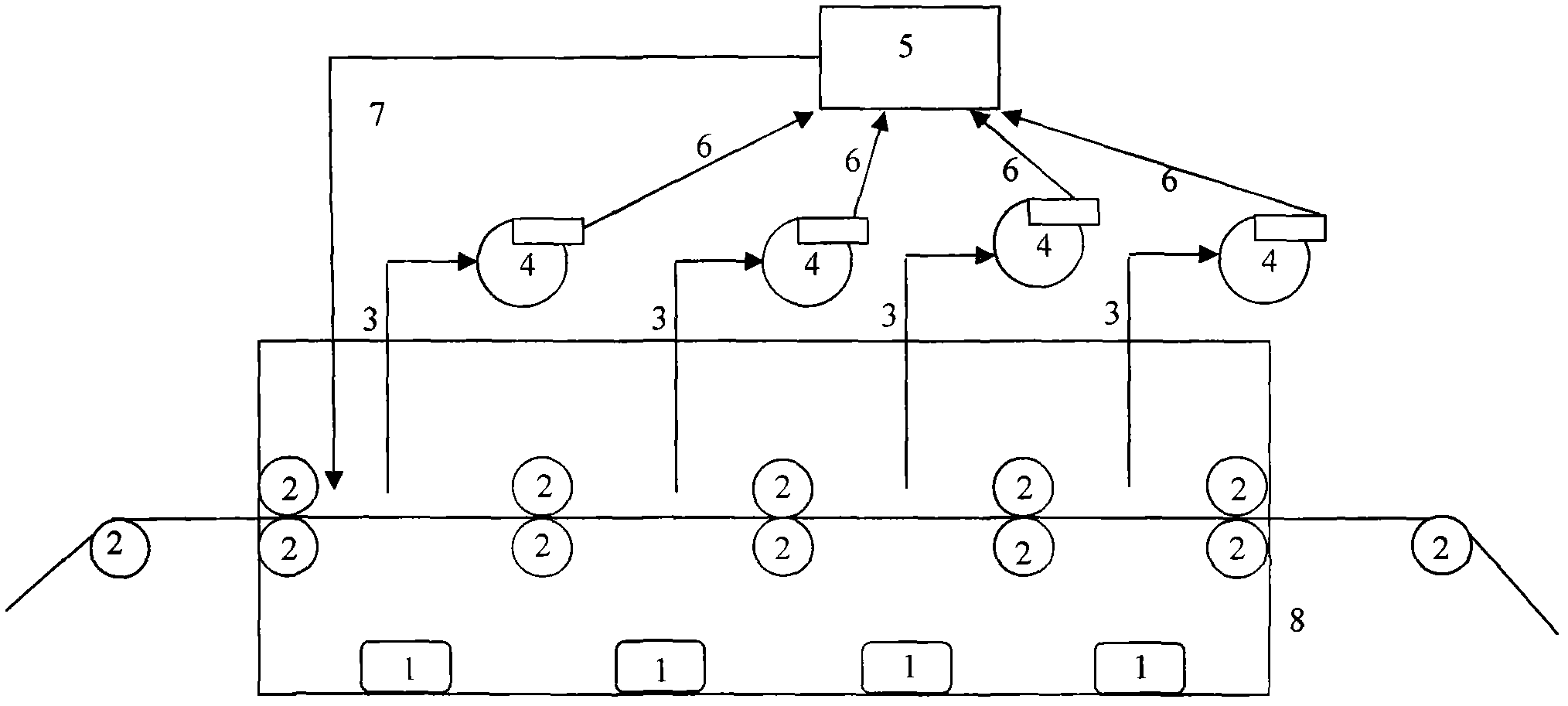

[0012] refer to figure 1 , is a flow chart of the roll-to-roll preparation method of the cadmium sulfide thin film of the present invention. Such as figure 1 As shown, the preparation method of the cadmium sulfide buffer layer of the present invention starts from step S1. Firstly, ammonia water is poured into the cadmium acetate solution of a specified concentration and stirred evenly. Then proceed to step S2, pour in the thiourea solution of the specified concentration, and continue to stir until a colorless and transparent solution is obtained. In step S3, the buffer solution ammonium acetate solution is used to adjust the pH value to pH 8-10. In step S4, the flexible substrate is dried in an oven and placed on rollers. Then proceed to step S5, start to heat the reaction solution, and this process is carried out in the liquid storage tank wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com