Piezoelectric actuator and piezoelectric motor

A piezoelectric driver and driving voltage technology, which is applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve complex manufacturing processes, external interference, and large power consumption and other issues, to achieve the effect of convenient production, avoiding failure problems, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

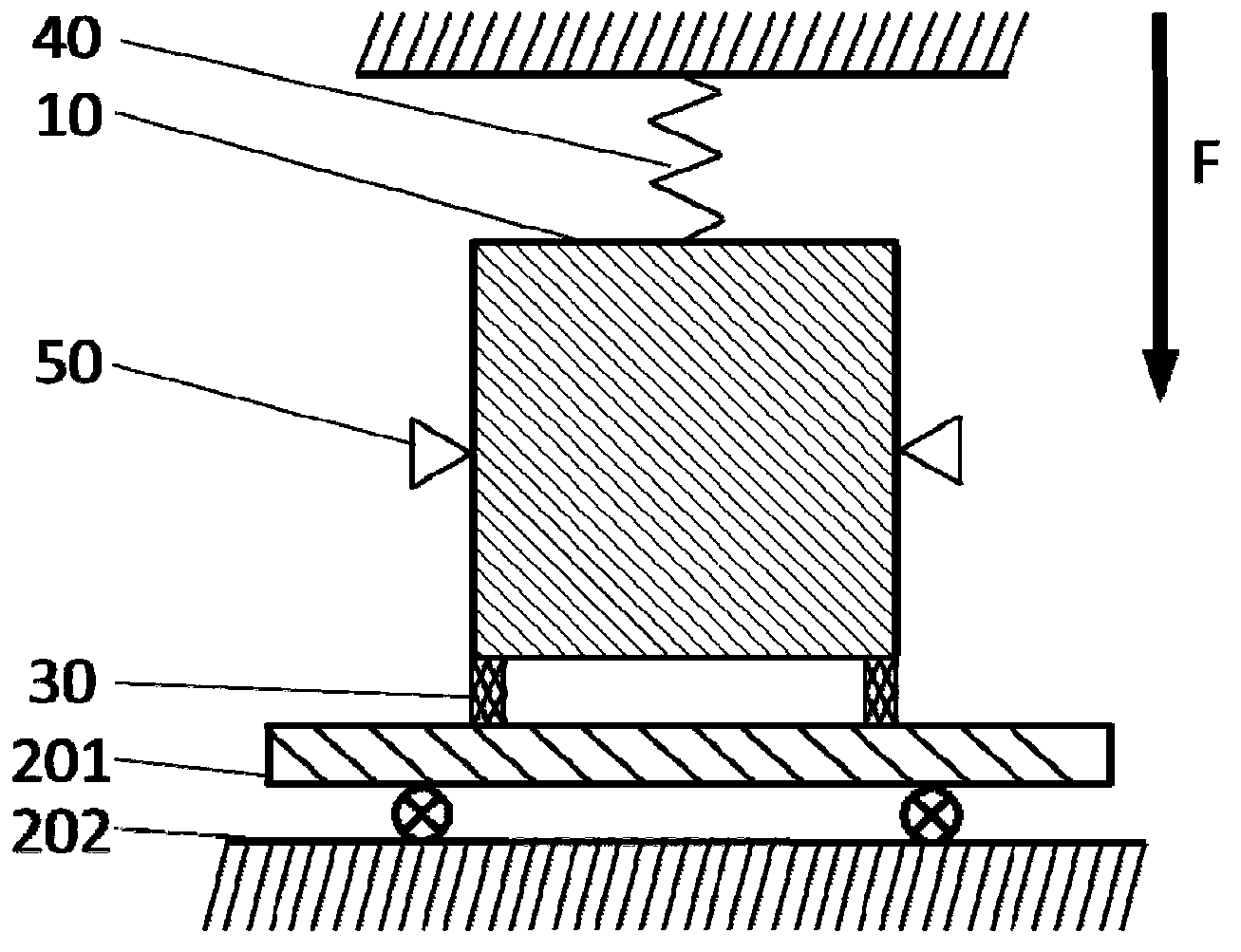

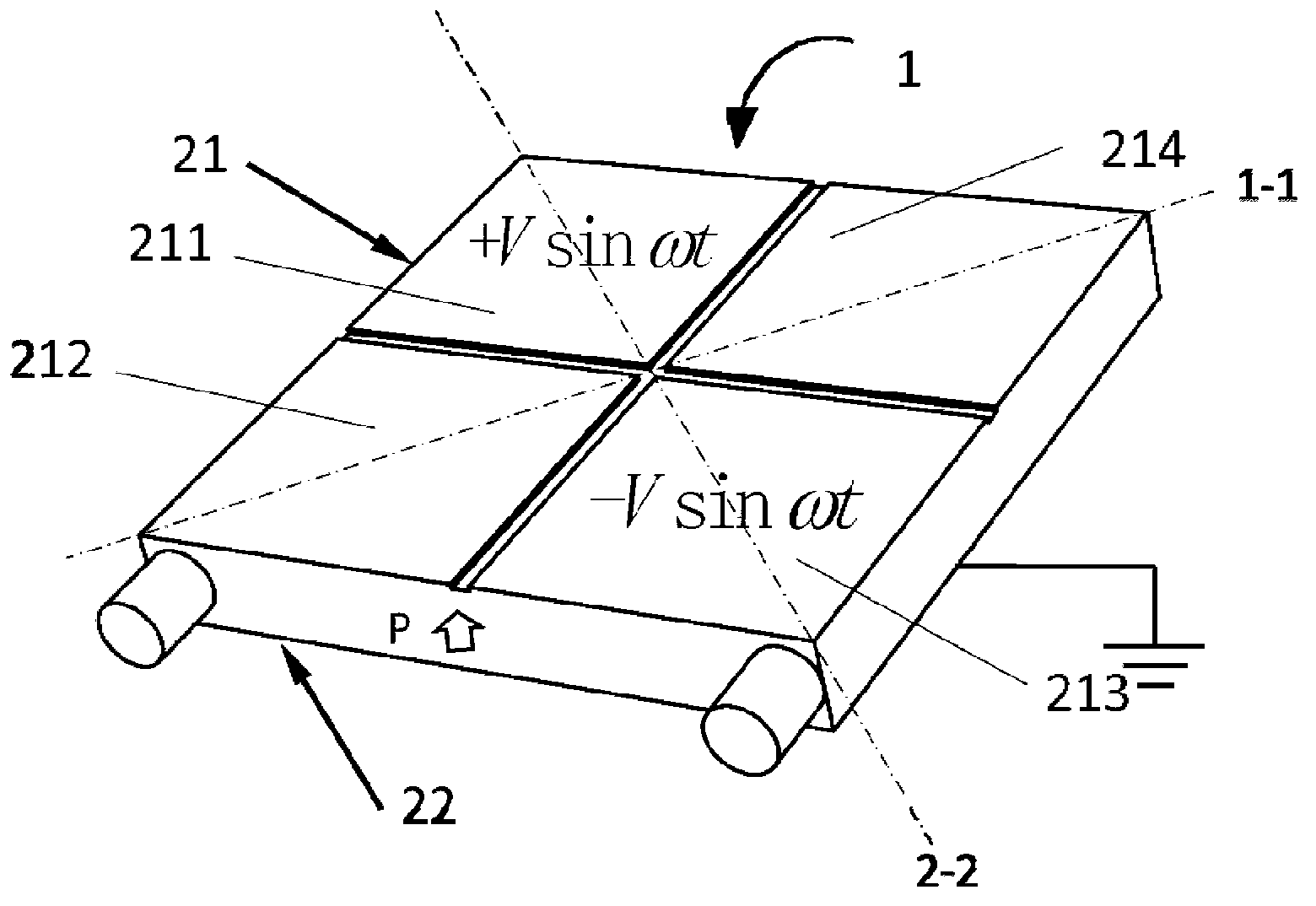

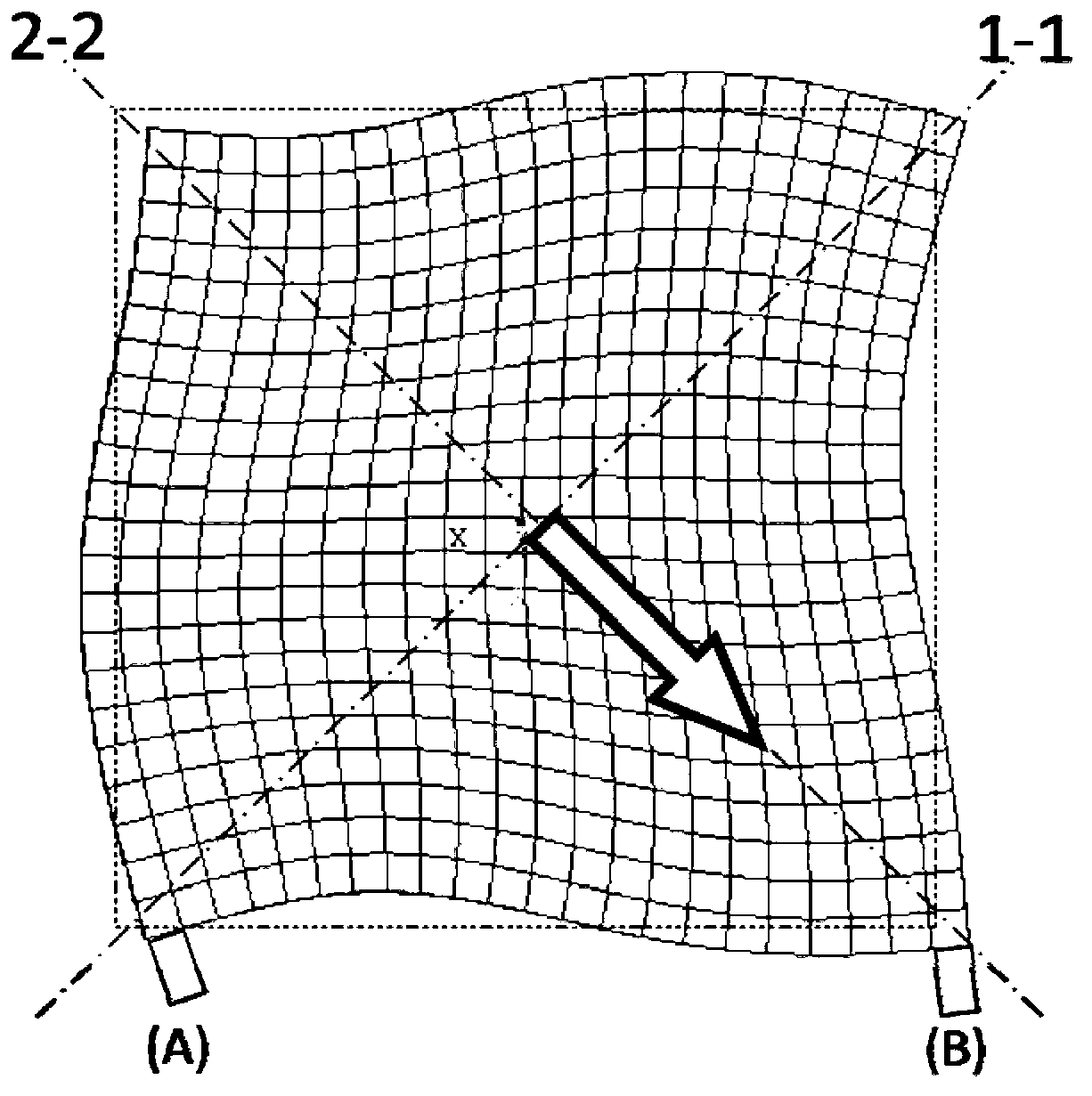

[0029] In view of the traditional piezoelectric L1-B2 dual-vibration mode piezoelectric motor, the piezoelectric driver has complex structures and manufacturing processes, and the cost of large-scale production of the piezoelectric driver is relatively high. The present invention provides a piezoelectric driver that can work in the first The single working mode of the bending vibration along the diagonal in the step plane effectively simplifies the structure of the piezoelectric actuator. The single working mode and simple square plate structure can effectively reduce the manufacturing cost of the piezoelectric driver; at the same time, it can also simplify the design of the driving circuit and avoid the problem of driving failure caused by external interference when working in two modes.

[0030] Specifically, the driver provided by the present invention may include a piezoelectric body, the piezoelectric body is a square plate-shaped structure, and the piezoelectric body is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com