Hydraulic automatic tensioner

A hydraulic and tensioner technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., to achieve the effect of simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

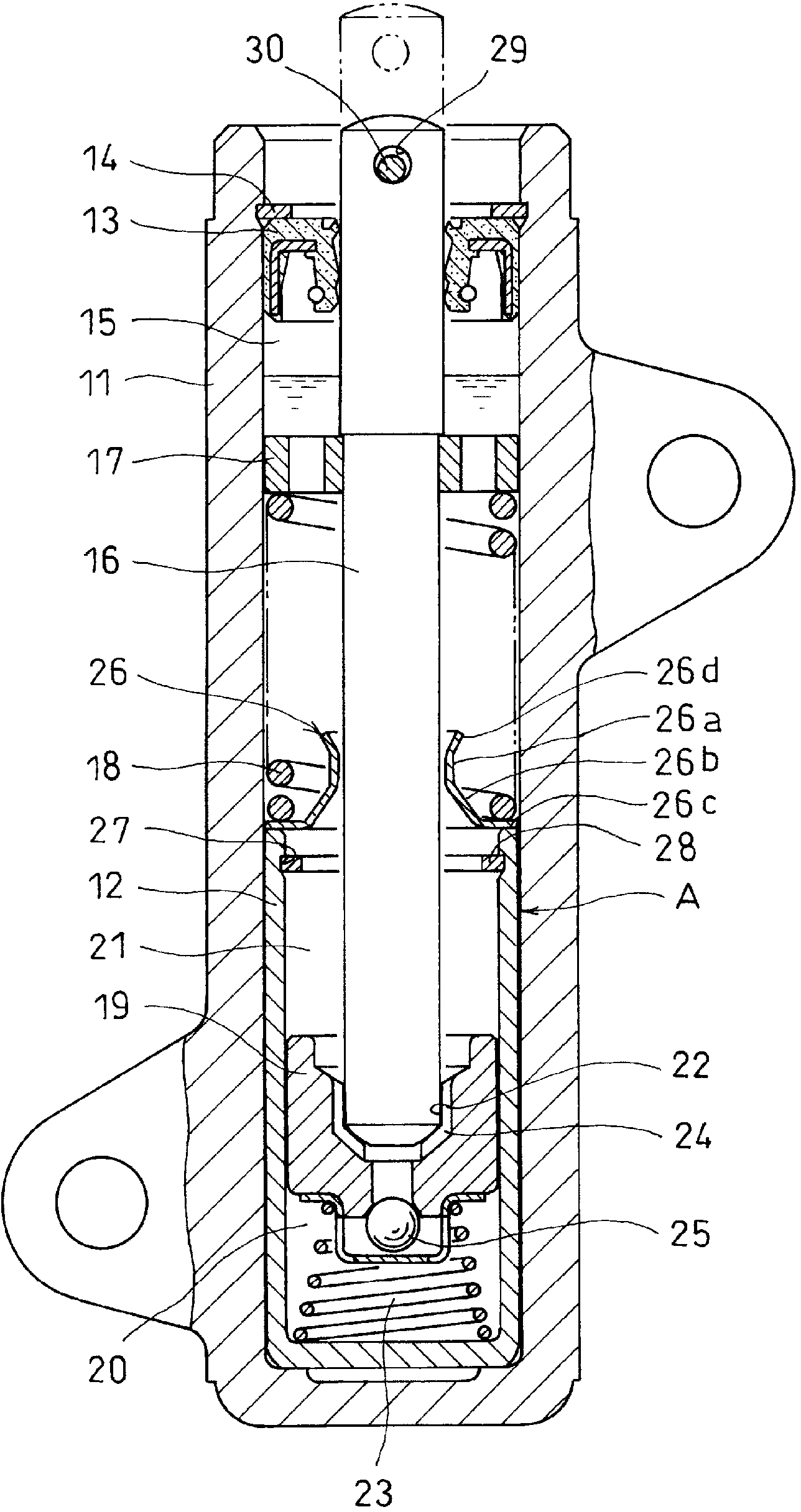

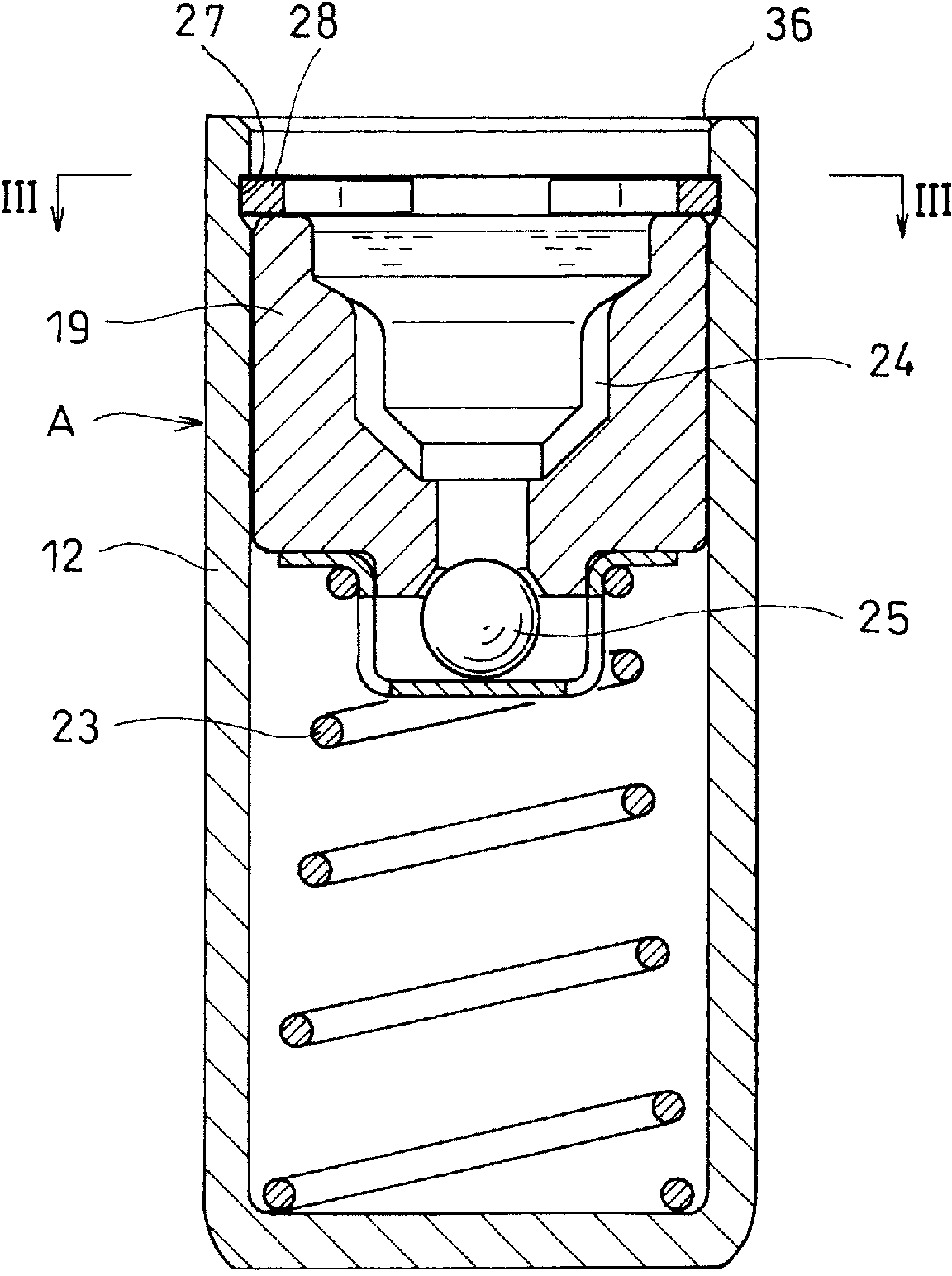

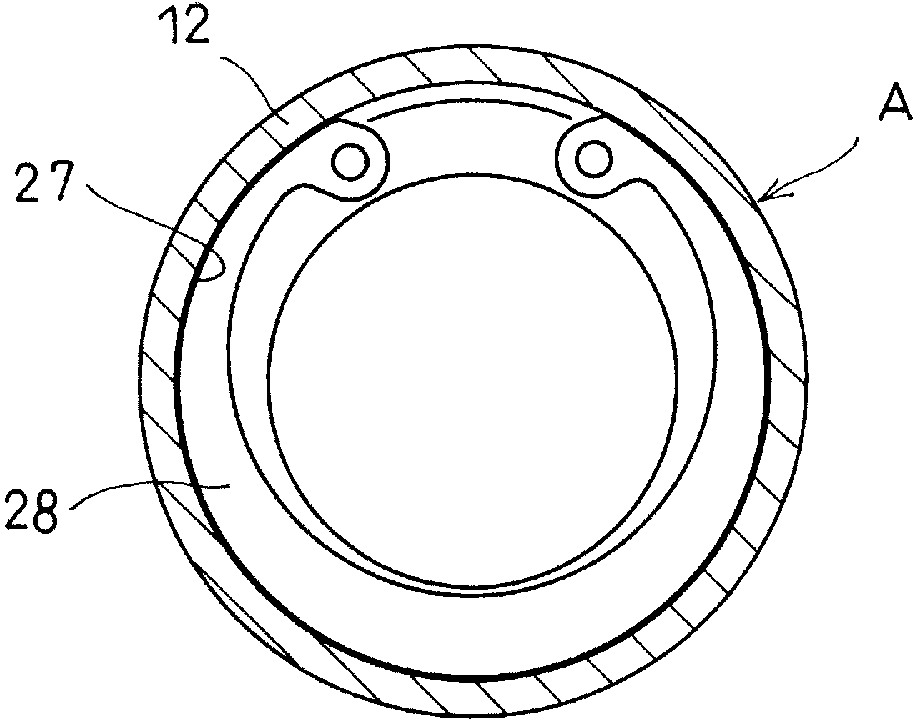

[0043] Embodiments of the present invention will be described below based on the drawings. Such as figure 1 As shown, the hydraulic automatic tensioner related to the present invention has a cylinder 11 installed in the engine block. The cylinder 11 is formed of aluminum alloy and has a bottom, and a valve sleeve 12 is fitted inside. The air valve sleeve 12 is made of steel and has a bottom.

[0044] The upper opening of the cylinder 11 is sealed by incorporating a sealing member 13 formed of an oil seal, and the sealing member 13 is prevented from falling off by a stop ring 14 installed on the inner periphery of the upper end of the cylinder 11, and the sealing member 13 is used to prevent filling into the cylinder 11. The internal working oil leaks to the outside. Furthermore, an air retention portion 15 is provided on the oil surface of the working oil.

[0045] On the push rod 16 that penetrates the sealing member 13 in a slidable manner and is located above the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com