Polyvinyl alcohol/graphene oxide composite film preparation method

A graphene composite and polyvinyl alcohol technology, applied in the field of preparation of polyvinyl alcohol/graphene oxide composite films, can solve problems such as poor oxygen barrier properties, achieve great practical and popularization value, good environmental protection, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

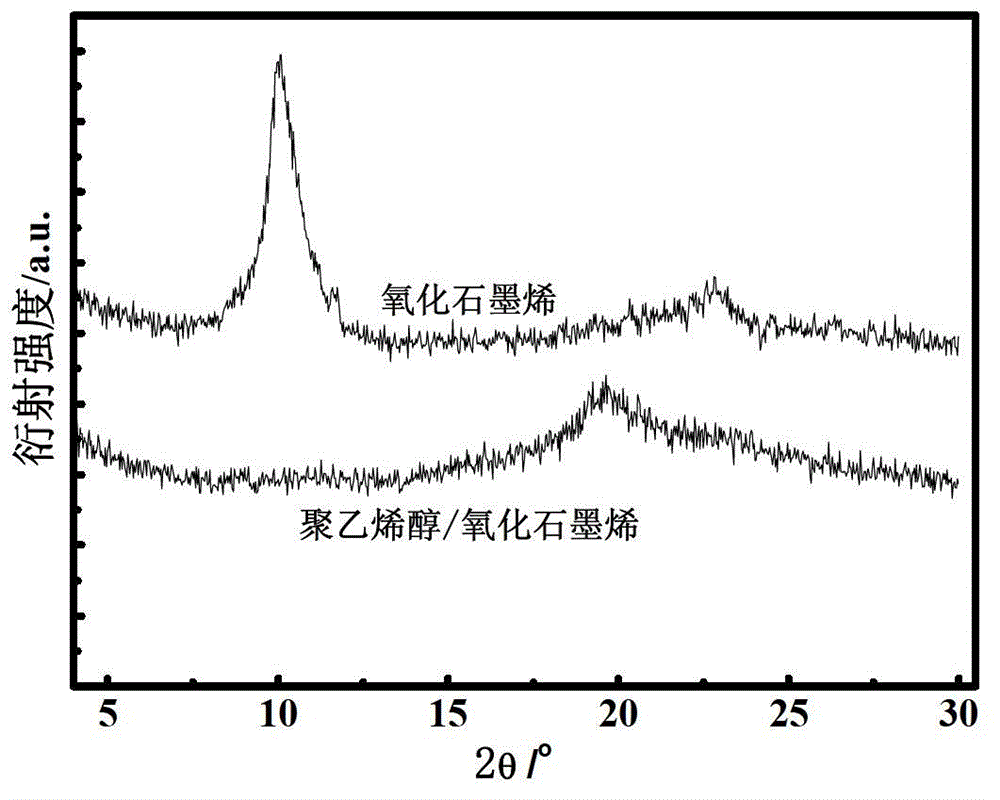

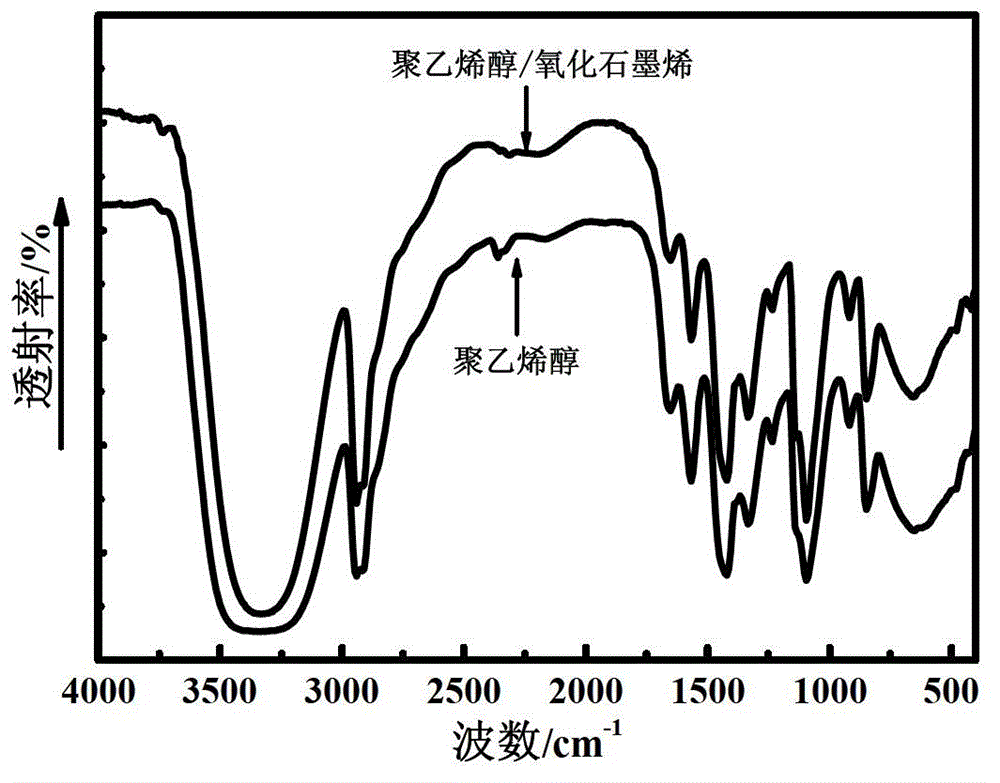

[0051] First weigh 5g of expandable graphite and add it to 125ml of 98% concentrated H 2 SO 4 , stirred in an ice-water bath to prepare mixture a; then to mixture a, gradually add 20g KMnO 4 , the reaction was carried out at a temperature of 10°C for 2h, and then the reaction was continued for 1h in a constant temperature water bath at 35°C to obtain a mixture b; then 500ml of deionized water and 10ml of 30% H 2 o 2 , stir well and filter the mixture while hot to obtain a pasty mixture; wash the pasty mixture repeatedly with 40ml of 5% HCl solution and a large amount of deionized water until there is no SO in the filtrate 4 2- , and then disperse the pasty mixture in 3000ml of deionized water by ultrasonic action, and finally dry the dispersion at 50°C for 48h to obtain 7g of dry graphite oxide.

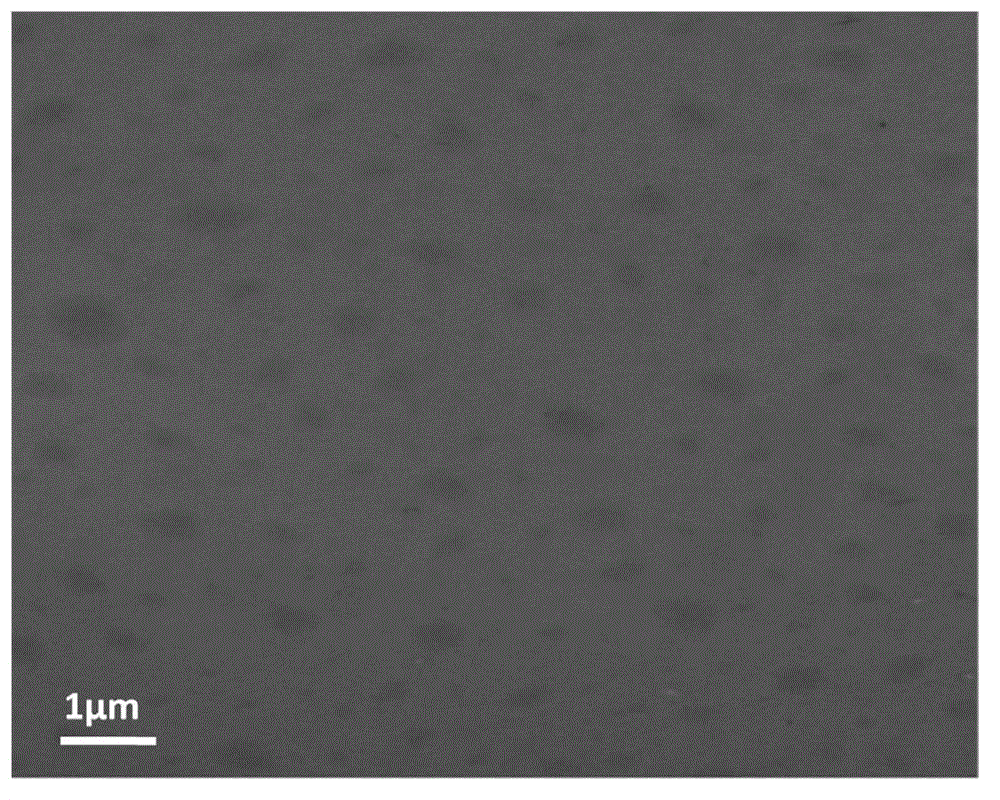

[0052] Take 0.1g of dry graphite oxide and add it to 100ml of deionized water, ultrasonicate at 25°C with an ultrasonic power of 100W, and stir for 2h to obtain a graphene oxide ...

Embodiment 2

[0059] First weigh 4g of expandable graphite and add it to 100ml of 98% concentrated H 2 SO 4 , stirred in an ice-water bath to prepare mixture a; then to mixture a, gradually add 18g KMnO 4 , the reaction was carried out at a temperature of 12°C for 2h, and then the reaction was continued for 1h in a constant temperature water bath at 35°C to obtain a mixture b; then 450ml of deionized water and 8ml of 30% H 2 o 2 , stir well and filter the mixture while hot to obtain a pasty mixture; wash the pasty mixture repeatedly with 35ml of 5% HCl solution and a large amount of deionized water until there is no SO in the filtrate 4 2- , and then disperse the pasty mixture in 2500ml of deionized water by ultrasonic action, and finally dry the dispersion at 40°C for 72h to obtain 6g of dry graphite oxide.

[0060] Add 0.05g of dry graphite oxide into 50ml of deionized water, ultrasonicate at 30°C with an ultrasonic power of 100W, and stir for 1.5h to obtain a graphene oxide colloidal...

Embodiment 3

[0063] First weigh 2g of expandable graphite and add it to 100ml of concentrated H2O with a concentration of 98%. 2 SO 4 , stirred in an ice-water bath to prepare mixture a; then to mixture a, gradually add 10g KMnO 4 , the reaction was carried out at a temperature of 15°C for 2h, and then the reaction was continued for 1h in a constant temperature water bath at 35°C to obtain a mixture b; then 400ml of deionized water and 5ml of 30% H 2 o 2 , stir well and filter the mixture while hot to obtain a pasty mixture; wash the pasty mixture repeatedly with 30ml of 5% HCl solution and a large amount of deionized water until there is no SO in the filtrate 4 2- , and then the pasty mixture was dispersed in 2000ml of deionized water by ultrasonic action, and finally the dispersion was dried at 45°C for 60h to obtain 3.4g of dry graphite oxide.

[0064] Add 0.025g of dry graphite oxide into 25ml of deionized water, ultrasonicate at 40°C with an ultrasonic power of 100W, and stir for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com