Preparation method for doping type four-element multicolor fluorescent Ag-N-In-S quantum dot

A technology of ag-zn-in-s and quantum dots, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of high process requirements and complicated preparation of precursors, and achieve simplified preparation process, strong repeatability, The effect of short synthesis cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In the first step, weigh 34.2mg (0.2mmol) AgNO 3 , 44.8 mg (0.2 mmol) InCl 3 , 27.6mg (0.2mmol) ZnCl 2 , 282.8mg (1.0mmol) of oleic acid and 809.2mg (4mmol) of dodecyl mercaptan were placed in a 100mL three-necked flask, and 6mL of octadecene solvent was added.

[0032] In the second step, 32.4mg (1.0mmol) of sulfur powder was weighed, dissolved in 4mL of oleylamine, and placed in a 50°C water bath to fully dissolve the sulfur powder in oleylamine.

[0033] In the third step, under the conditions of magnetic stirring and argon protection, the precursor solution in the first step is heated to 60°C for 30min, and then the temperature is increased by 60°C→90°C→120°C→150°C→ During the heating process of 170°C, the temperature was raised to 170°C, and after stabilizing for 2 minutes, the S powder dissolved in oleylamine was injected and reacted for 5-90 minutes.

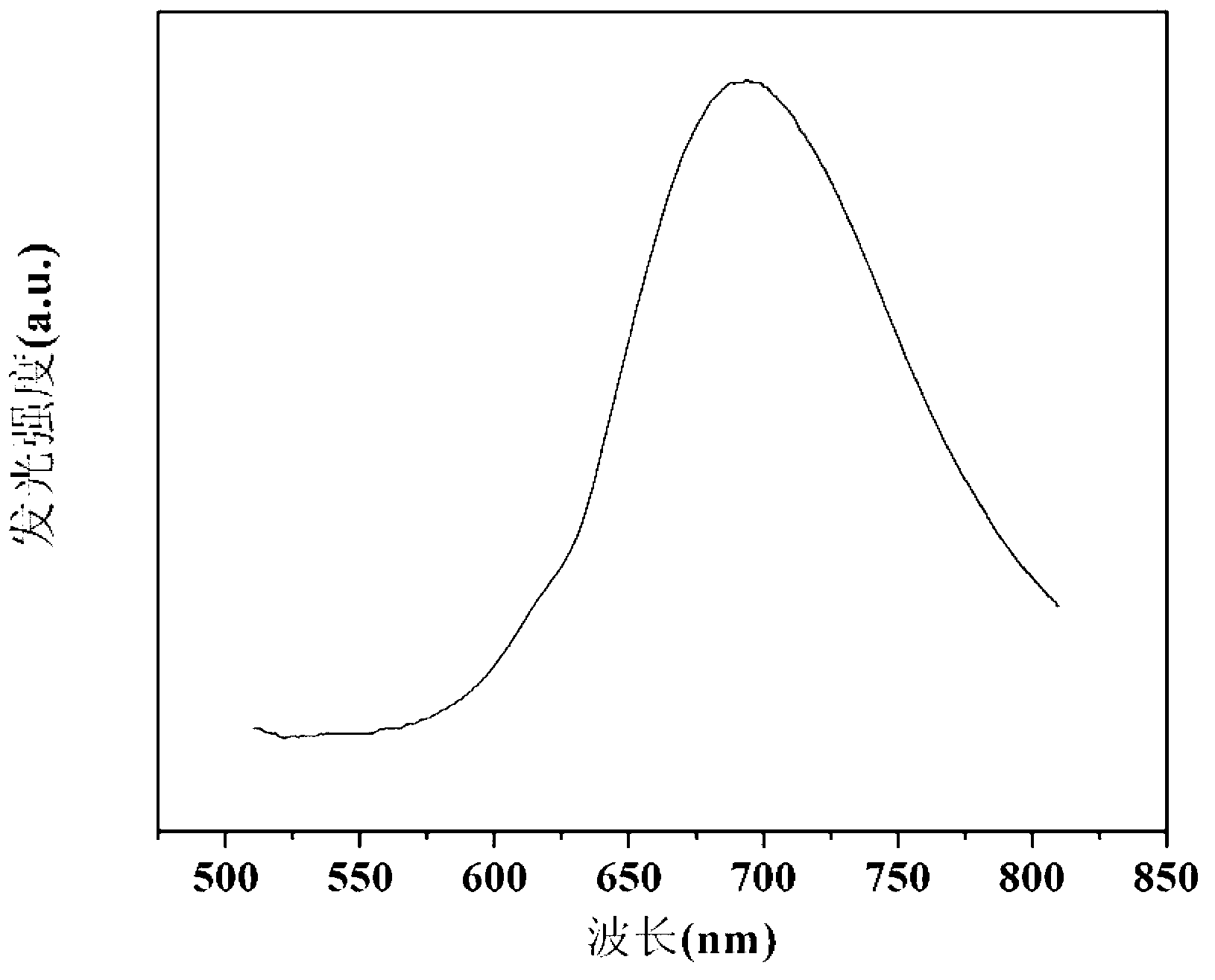

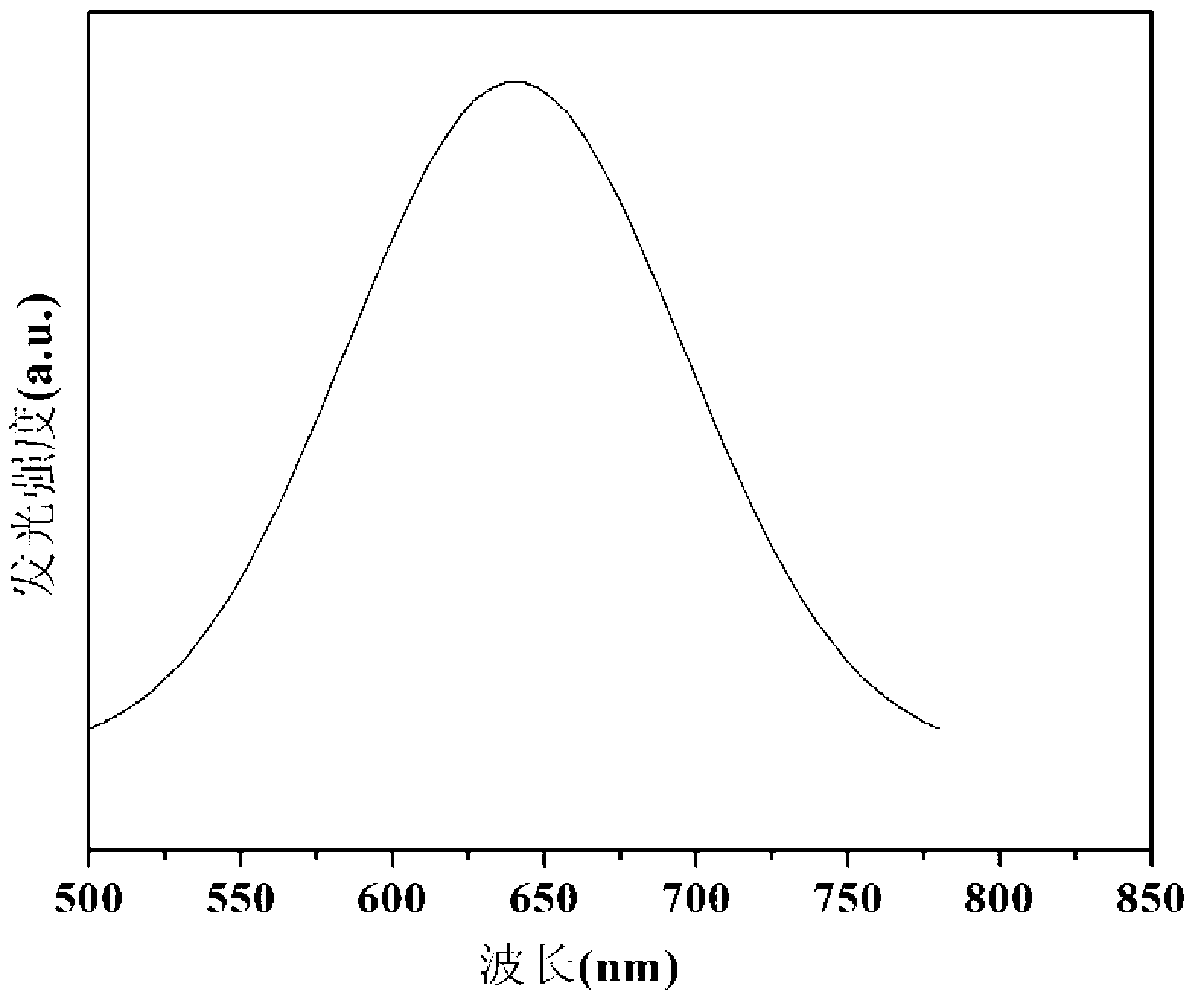

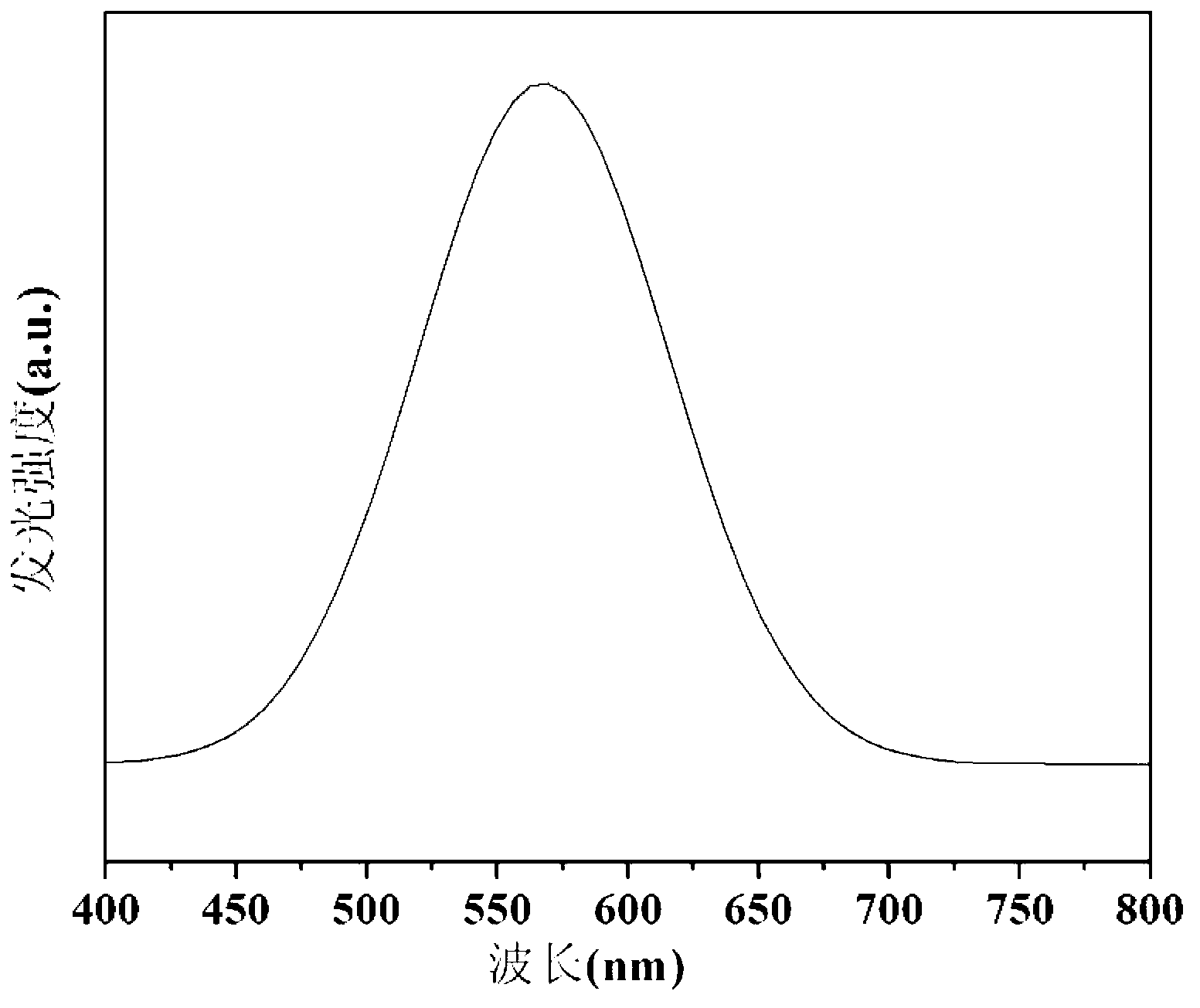

[0034] The fourth step is to take samples when the reaction time is 5min, 10min, 15min, 20min, 30min, 45min, ...

Embodiment 2

[0038] In the first step, weigh 17.2mg (0.1mmol) AgNO 3 , 44.2mg (0.2mmol) InCl 3 , 27.8mg (0.2mmol) ZnCl 2 , 283.2mg (1.0mmol) of oleic acid and 809.9mg (4mmol) of dodecyl mercaptan were placed in a 100mL three-necked flask, and 6mL of octadecene solvent was added.

[0039] In the second step, 32.2mg (1.0mmol) of sulfur powder was weighed, dissolved in 4mL of oleylamine, and placed in a 50°C water bath to fully dissolve the sulfur powder in oleylamine.

[0040] In the third step, under the conditions of magnetic stirring and argon protection, the precursor solution in the first step is heated to 60°C for 30min, and then the temperature is increased by 60°C→90°C→120°C→150°C→ During the heating process of 170°C, the temperature was raised to 170°C, and after stabilizing for 2 minutes, the S powder dissolved in oleylamine was injected and reacted for 5-90 minutes.

[0041] The fourth step is to take samples when the reaction time is 5min, 10min, 15min, 20min, 30min, 45min, 60...

Embodiment 3

[0045] The first step, the first step, weigh 6.9mg (0.04mmol) AgNO 3 , 44.5mg (0.2mmol) InCl 3 , 27.5mg (0.2mmol) ZnCl 2 , 282.6mg (1.0mmol) of oleic acid and 810.2mg (4mmol) of dodecyl mercaptan were placed in a 100mL three-necked flask, and 6mL of octadecene solvent was added.

[0046]In the second step, 32.0mg (1.0mmol) of sulfur powder was weighed, dissolved in 4mL of oleylamine, and placed in a 50°C water bath to fully dissolve the sulfur powder in oleylamine.

[0047] In the third step, under the conditions of magnetic stirring and argon protection, the precursor solution in the first step is heated to 60°C for 30min, and then the temperature is increased by 60°C→90°C→120°C→150°C→ During the heating process of 170°C, the temperature was raised to 170°C, and after stabilizing for 2 minutes, the S powder dissolved in oleylamine was injected and reacted for 5-90 minutes.

[0048] The fourth step is to take samples when the reaction time is 5min, 10min, 15min, 20min, 30mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com