Integral horizontally moving type traveling shuttering construction device for long-strip-shaped uniform section concrete structure

A concrete structure and horizontal movement technology, applied in the field of industrial and civil construction projects, can solve the problems of repeated use of construction materials, large length of concrete structure, waste of manpower and material resources, etc., to save manpower and material resources, simple structure, and improved efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

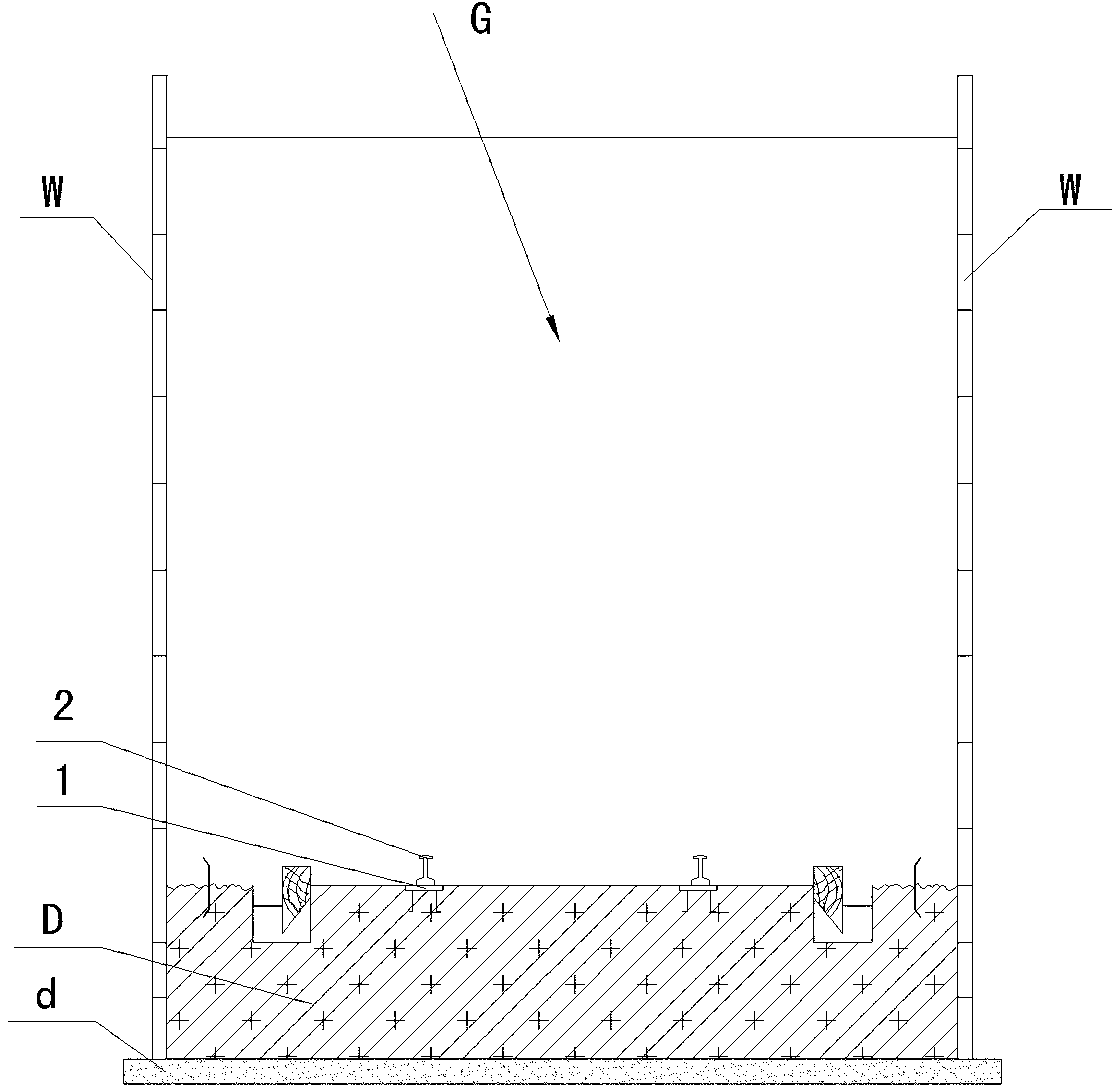

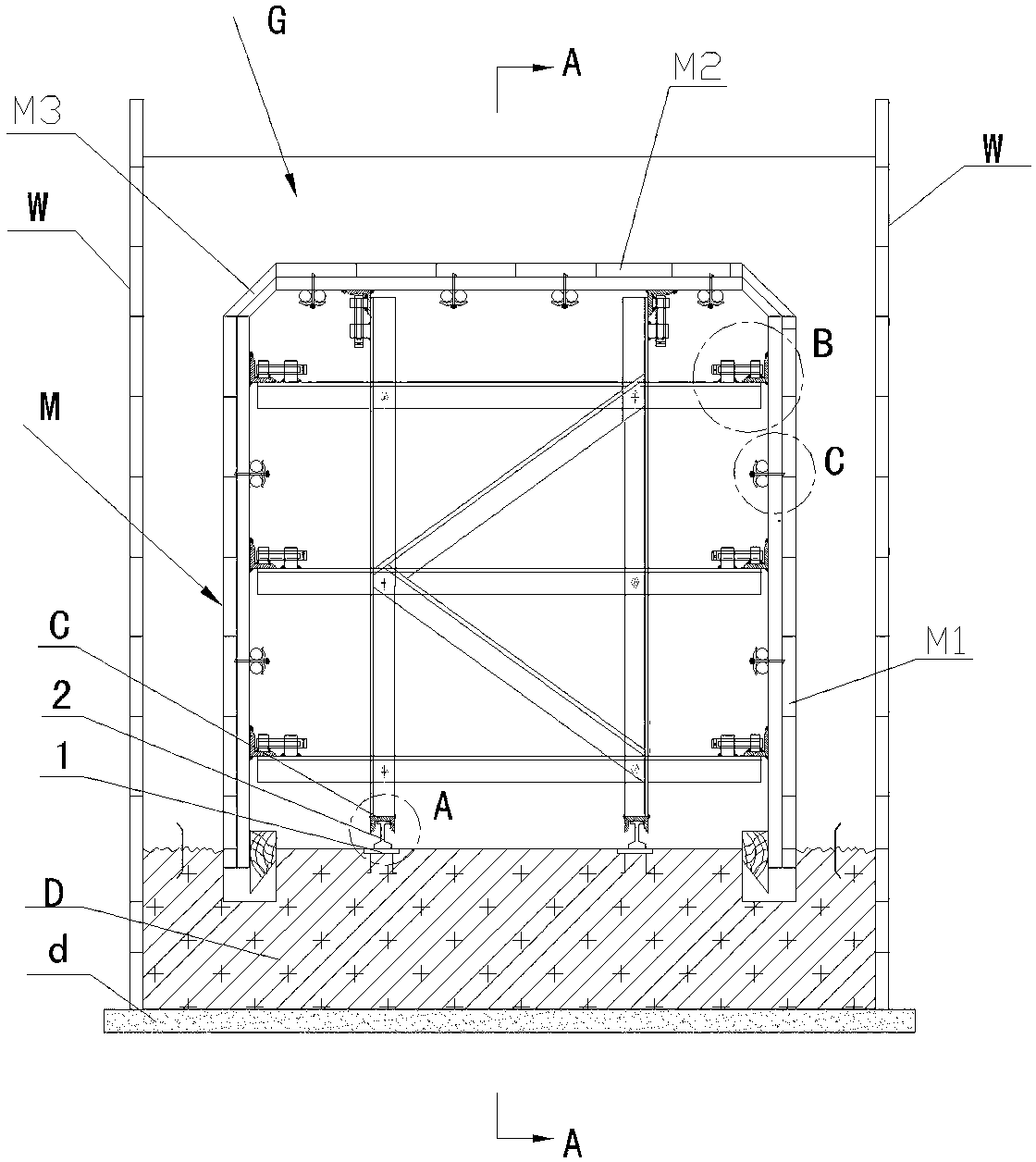

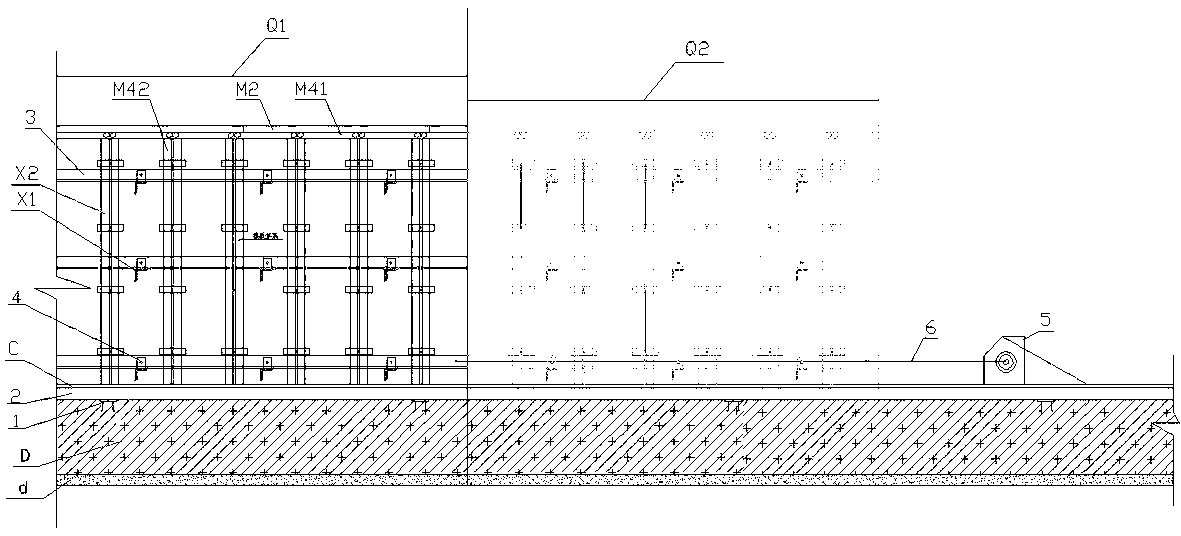

[0092] A pre-embedded steel plate 1 with a size of 100×100×6mm is set on the structural concrete base plate D;

[0093] After the concrete of the structural bottom plate is completed, the light steel rail 2 of type P24 is laid on the bottom plate;

[0094] Assemble the section steel frame X of type ∠80×10 on the light rail 2;

[0095] Install Ф50 bolt jacks 4 on both ends of the beam X1 of the section steel frame and the top of the vertical beam X2;

[0096] An angle steel 3 with a model of ∠125×80×8 is installed between the section steel frame X and the inner wall formwork system M, and an outer right-angle surface 31 of the angle steel 3 is fixed to the steel pipe formwork vertical corrugation M42 of the interior wall formwork system M , the other outer right-angle surface 32 is welded to the bottom of the first rectangular nut 42 of the bolt jack 4 .

Embodiment 2

[0098] On the basis of the above Example 1, for the construction of a cable engineering tunnel with a total length of 400m, a 20m-long section steel frame X and an inner wall formwork system M are used, and the device of the present invention is reused for a total of 20 times, which can shorten the construction period. More than four times, thereby significantly improving work efficiency and greatly reducing engineering costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com