Determination method of bearing capacity of overlong bored pile

A technique for bored piles, determination methods, applied in sheet pile walls, special data processing applications, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

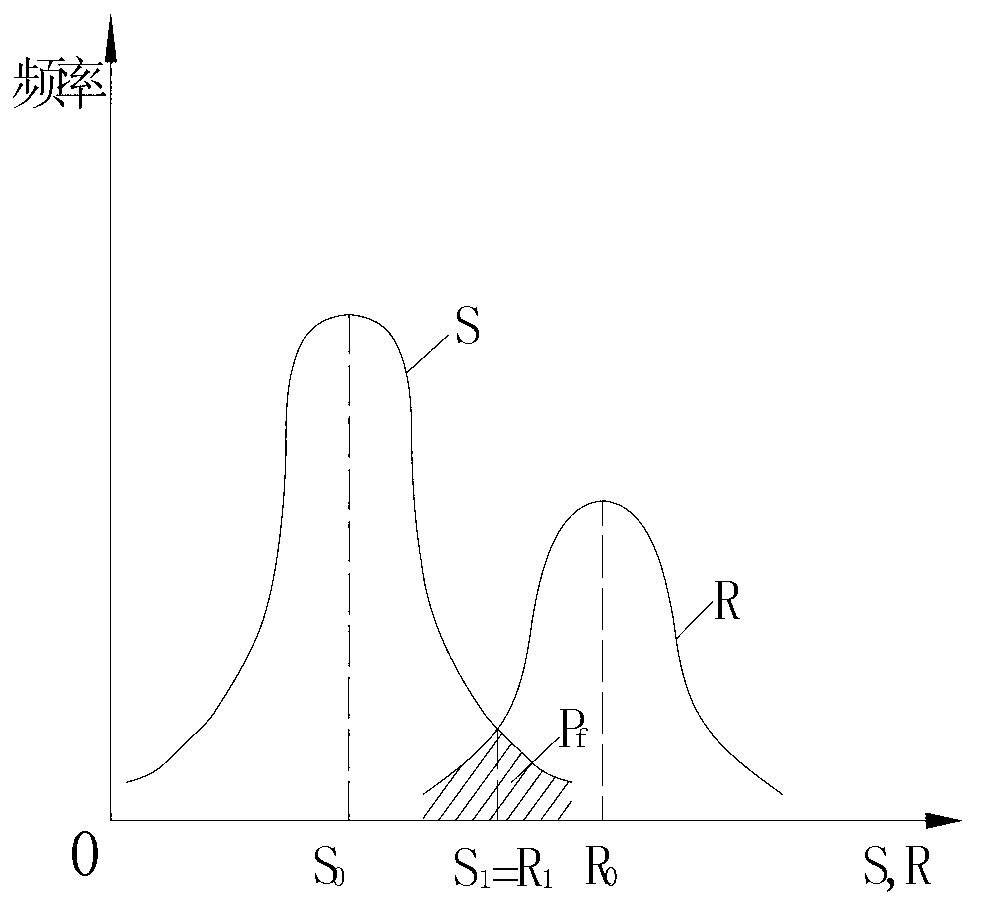

[0036] The traditional fixed value design method regards the bearing capacity of the pile foundation as a fixed value, and uses the total safety factor K to measure the safety (reliability) of the pile foundation. In fact, for pile foundations with different geological conditions and different soil layers that bear different loads (the ratio of dead load to live load, etc.), the actual reliability is different under the same safety factor. not clear. Because of the load effect S resistance R is a random variable. by figure 1 The S, R frequency distribution curve shown, the traditional safety factor is: K=μ R / μ s .

[0037] From figure 1 It can be seen that S and R are around the mean R 0 =μ R , S 0 =μ S It changes regularly, so for the same soil and the same pile type, the actual safety factor K is also non-fixed. For different soils and different pile types, the variability of R is different. When the same safety factor κ is used for design, the actual safety is different, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com