Molding method of window opening

A molding method and wood square technology, applied in the processing of building materials, on-site preparation of building components, formwork/formwork/work frame, etc., can solve the problems of easy cracks in inner windows, high construction costs, and thick inner plastering and other problems, to achieve the effect of solving the window leakage problem, high production efficiency and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

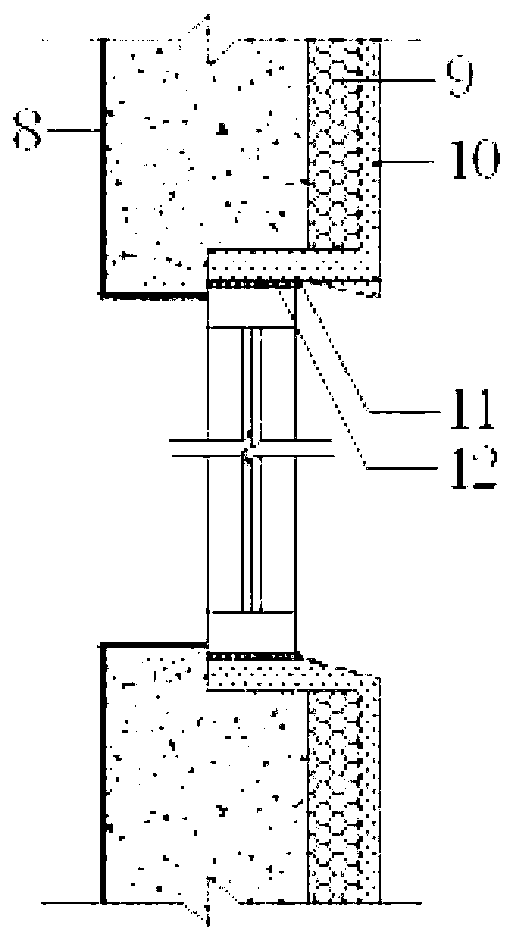

[0014] The specific process of realizing the one-time forming of the window opening in this embodiment includes three steps: setting up the opening formwork at the top of the window, setting up the opening formwork at the bottom of the window, and forming the window opening:

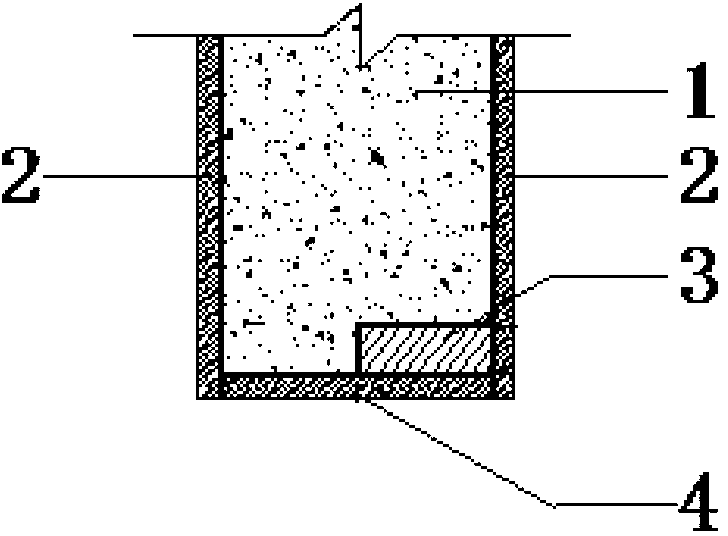

[0015] (1) Supporting of the opening formwork at the top of the window: First, the beam bottom formwork 4 is supported at the bottom of the structural beam 1, and the first wooden square 3 is added at the inner side of the beam bottom formwork 4 corresponding to the window. The size of the first wooden square 3 is based on the external The thickness of the window is determined; then the beam side formwork 2 is symmetrically supported on both sides of the structural beam 1, the height of the beam side formwork 2 is higher than the height of the structural beam 1, and the higher dimension is the width of the first wooden square 3;

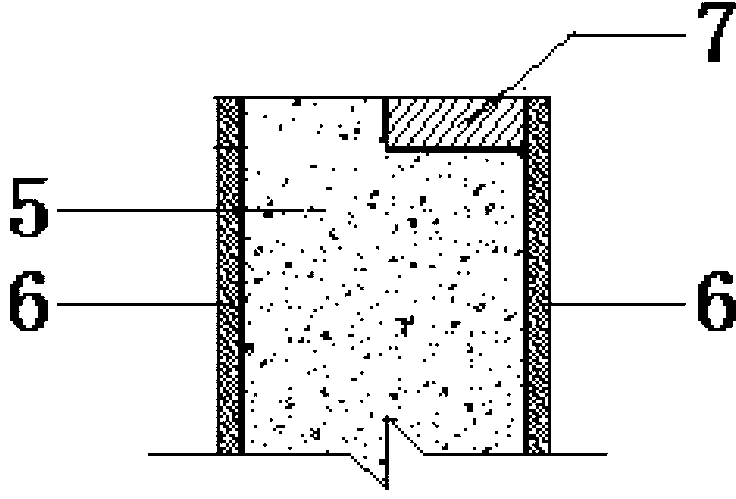

[0016] (2) Supporting of opening formwork at the bottom of the window: the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com