Method for measuring upper terminal difference and lower terminal difference of horizontal-type three-section feed water heater

A water heater and heater technology, applied in the direction of instruments, measuring devices, etc., can solve the problems of wrong and missing measurement data, and high measurement cost of data acquisition system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] Embodiment: In this embodiment, the method for calculating the upper end difference and the lower end difference of the high-pressure heater of a 330MW steam turbine unit #1 of Harbin Steam Turbine includes the following steps:

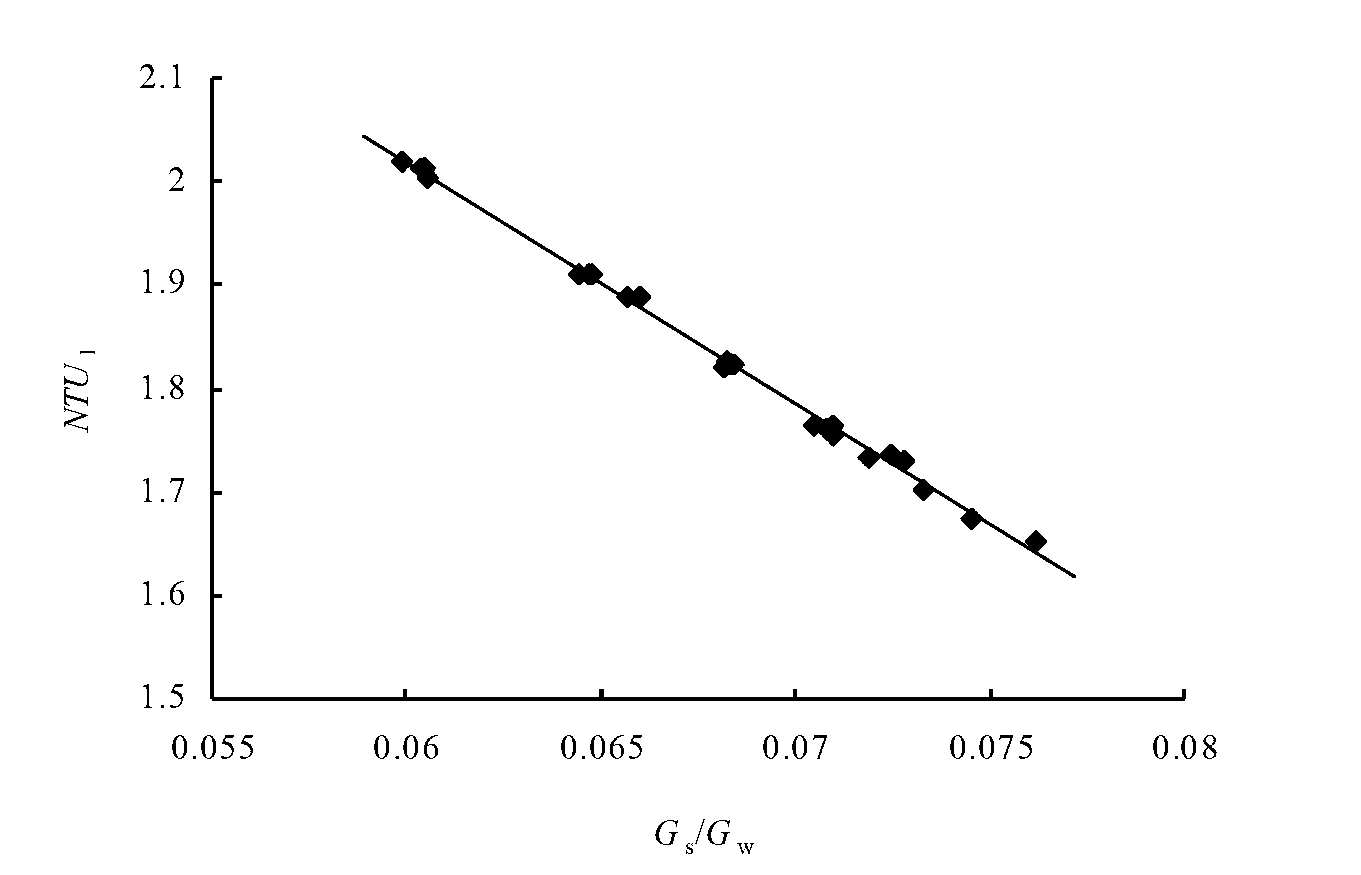

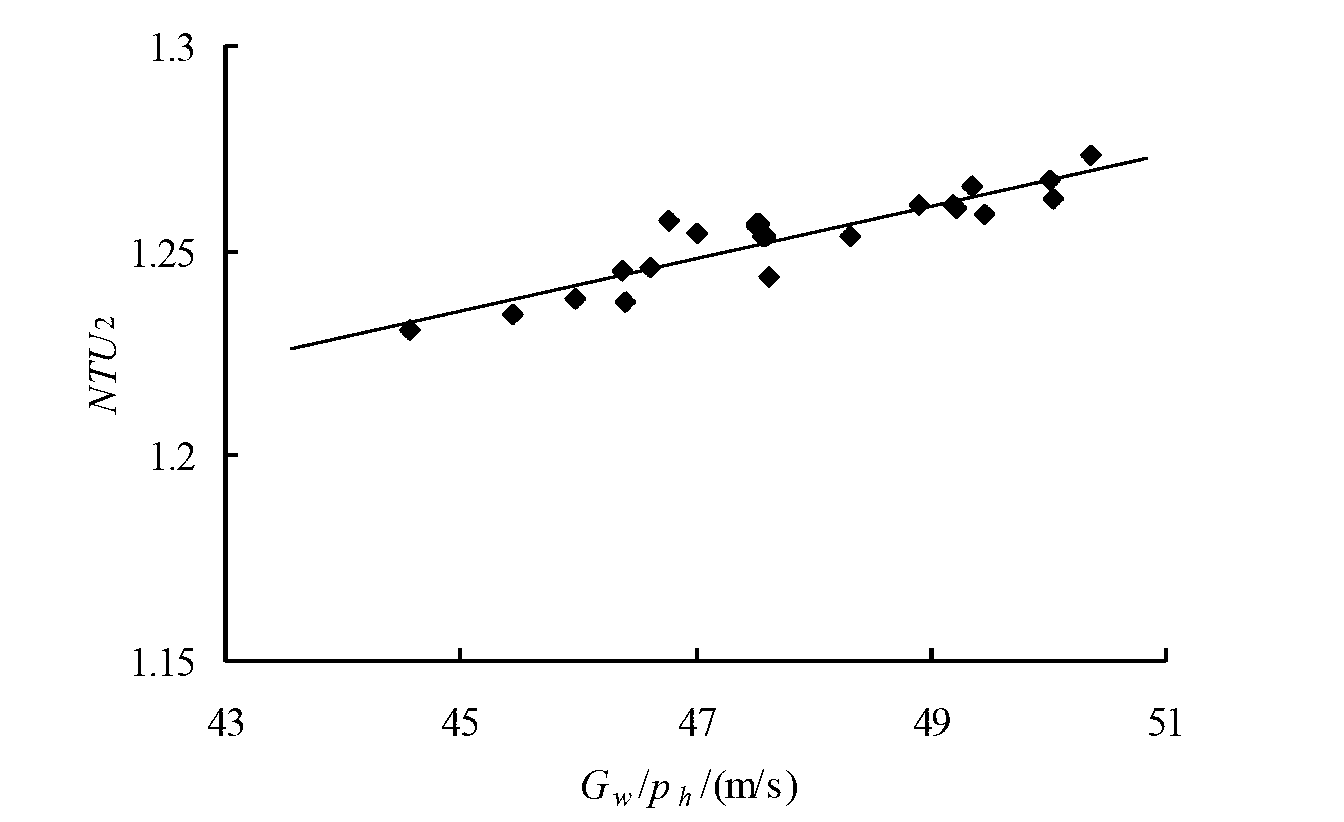

[0045] (1) Calculate the number of heat transfer units NTU in the drain cooling section of the heater 1 and extraction steam flow G s , Feedwater flow G w The ratio of G s / G w The linear relationship:

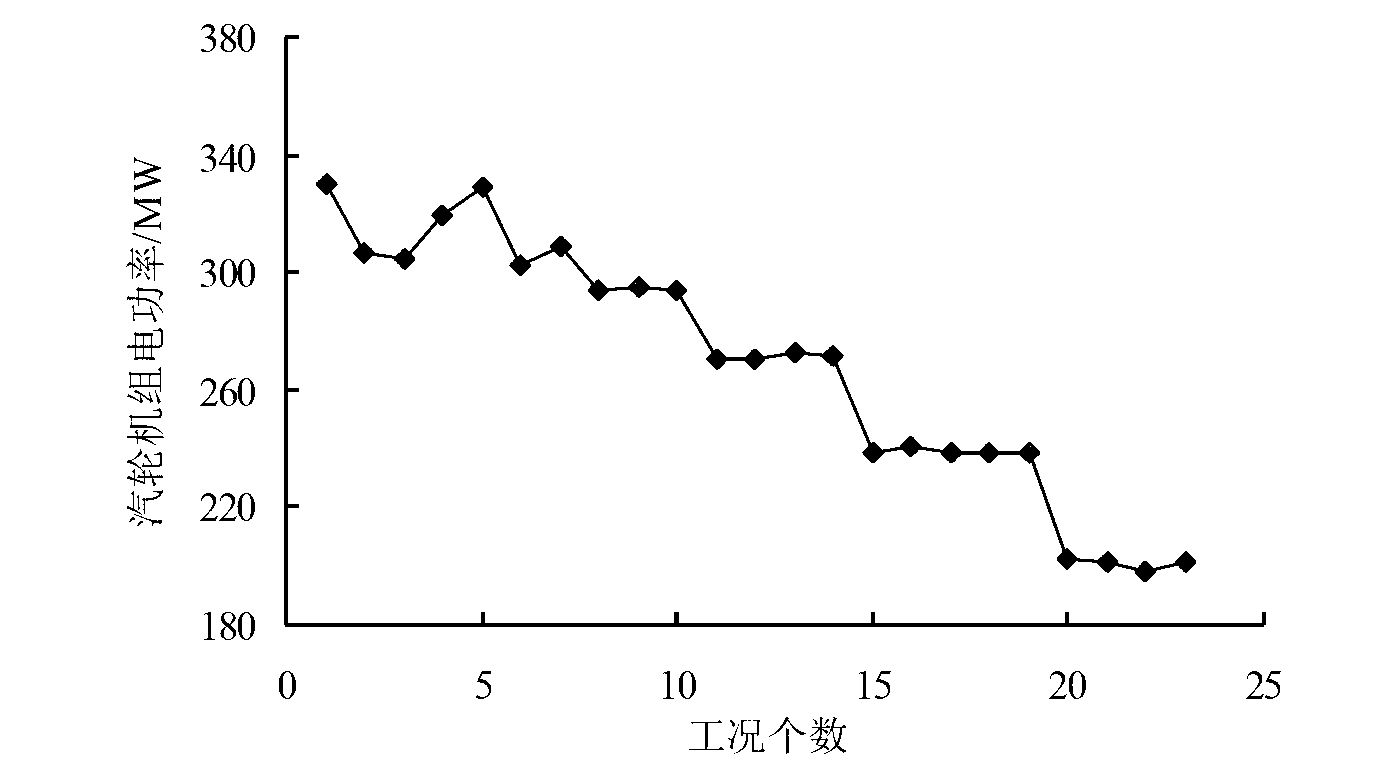

[0046] (11) Set 23 test conditions with different powers, and the 23 test conditions correspond to the changes in the electric power of the steam turbine generator set as follows: figure 1 As shown, under each test condition, the heater feed water pressure p is obtained by measuring the temperature and pressure measuring instrument w , saturation pressure p h , Hydrophobic temperature t od and feedwater inlet temperature t w1 , using the flow measuring instrument to measure the extraction steam flow G of the heater s and feedwater flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com