Acoustic characteristic detection device of forming material under state of controllable change of temperature and pressure

A technology of changing state and acoustic characteristics, applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc., can solve the problems that cannot meet the detection conditions of physical and mechanical properties, and achieve the effect of reducing manufacturing cost, reducing leakage, and long replacement path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings.

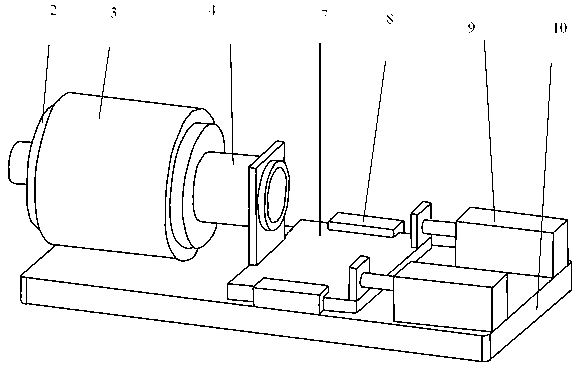

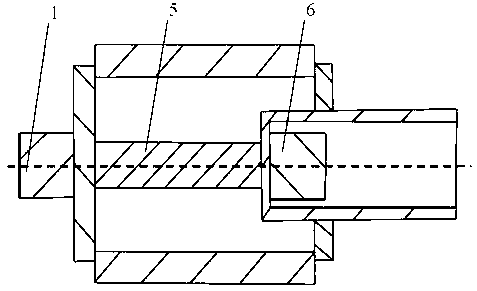

[0017] The present invention provides a device for detecting acoustic characteristics of forming materials under controllable change of temperature and pressure. The test cabin 3 is installed on the machine base 10, and the left and right symmetrical positions along the central axis of the test cabin 3 are installed on the machine base 10. Two A guide rail 8 and two hydraulic cylinders 9, the two hydraulic cylinders 9 are respectively connected to one end of the slide table 7, the slide table 7 is embedded in the two guide rails 8 to slide, and the other end of the slide table 7 is connected to the slide table sleeve 4; the forming material The sample 5 is horizontally placed in the test chamber 3, and the test chamber end cover 2 is installed at one end of the test chamber 3, and the test chamber end cover 2 is connected with the first transducer 1; The seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com