Parallel-connection electroluminescent wire

An electroluminescent wire and light-emitting wire technology, applied in the direction of electroluminescent light source, electric light source, light source, etc., can solve the problems of complex wiring and cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

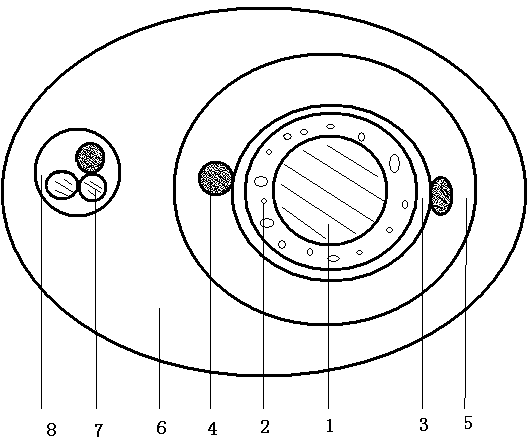

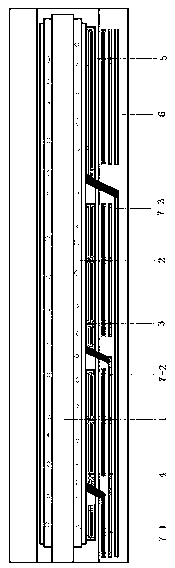

[0045] Preparation of luminous wire: 0.3 mm copper wire is used as the core wire electrode, the surface is coated with luminescent powder layer, the outer conductive layer is made of ITO material, the outer electrode is made of 0.1 mm silver-plated copper wire, and the transparent protective layer is made of PVC plastic.

[0046] The insulated metal wire is made of 0.1mm copper wire, and its surface is coated with an enamelled insulating layer. The surfaces of the three wires are red, blue and green. Three insulated metal wires are twisted into a cable and wrapped in PVC.

[0047] Insulated metal wires parallel to the luminous wires are wrapped in a layer of colored transparent plastic.

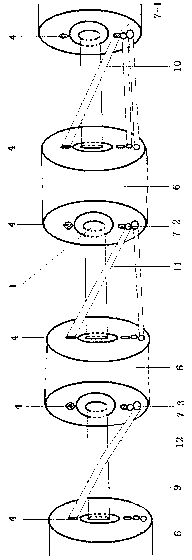

[0048] The luminous wires are cut into 200 meters each, a total of three, 600 meters in total, their core wire electrodes are connected in series in sequence, and the outer electrodes of the three sections of luminous wires are respectively connected to the red, blue and green insulated metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com