Bean grinding system of full-automatic coffee machine

A coffee machine, fully automatic technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of loss of worm gear rotation energy, coffee powder lifting, and the inability to quantitatively output the powder output of the coffee machine, so as to achieve low equipment costs. , compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

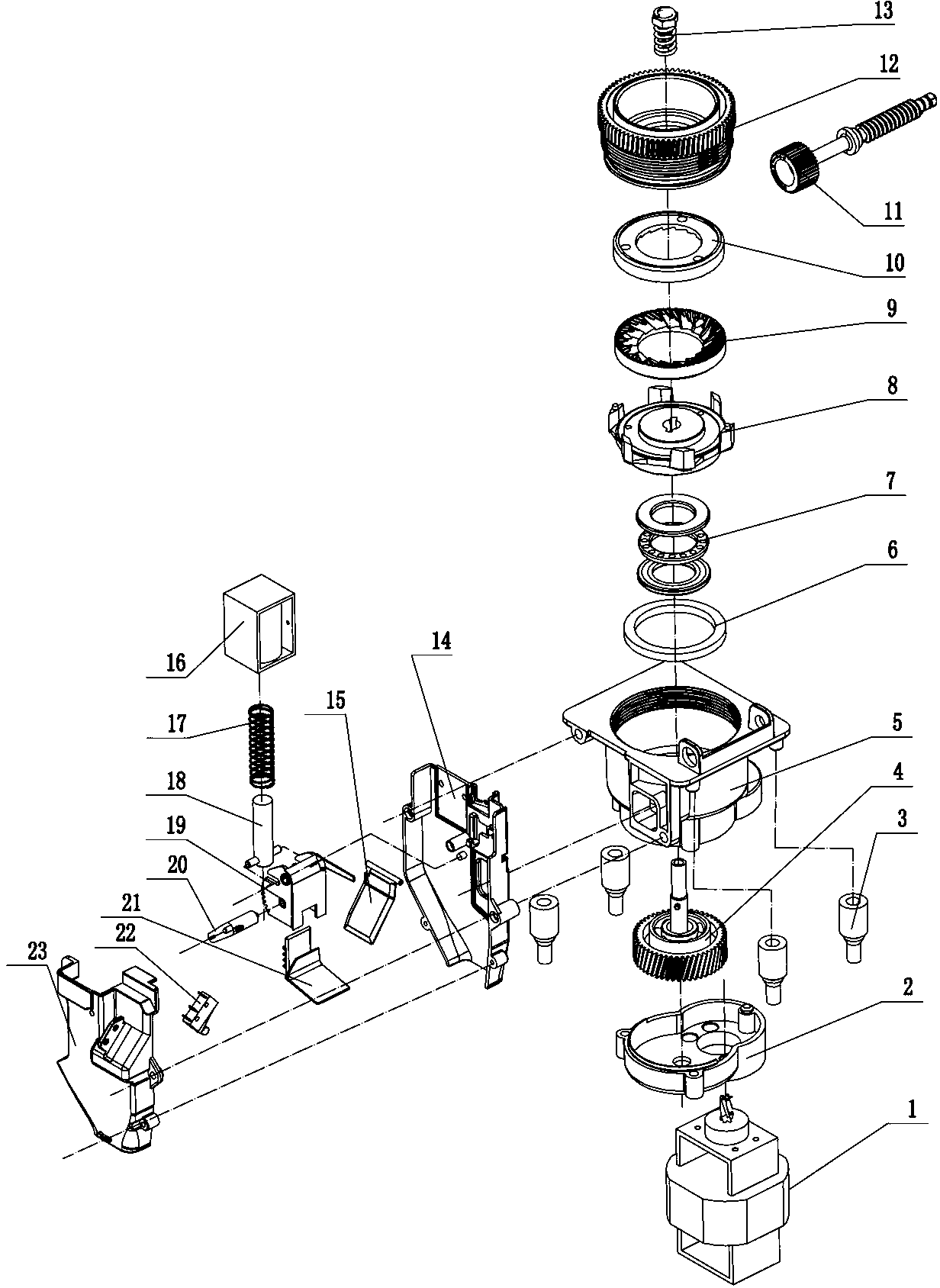

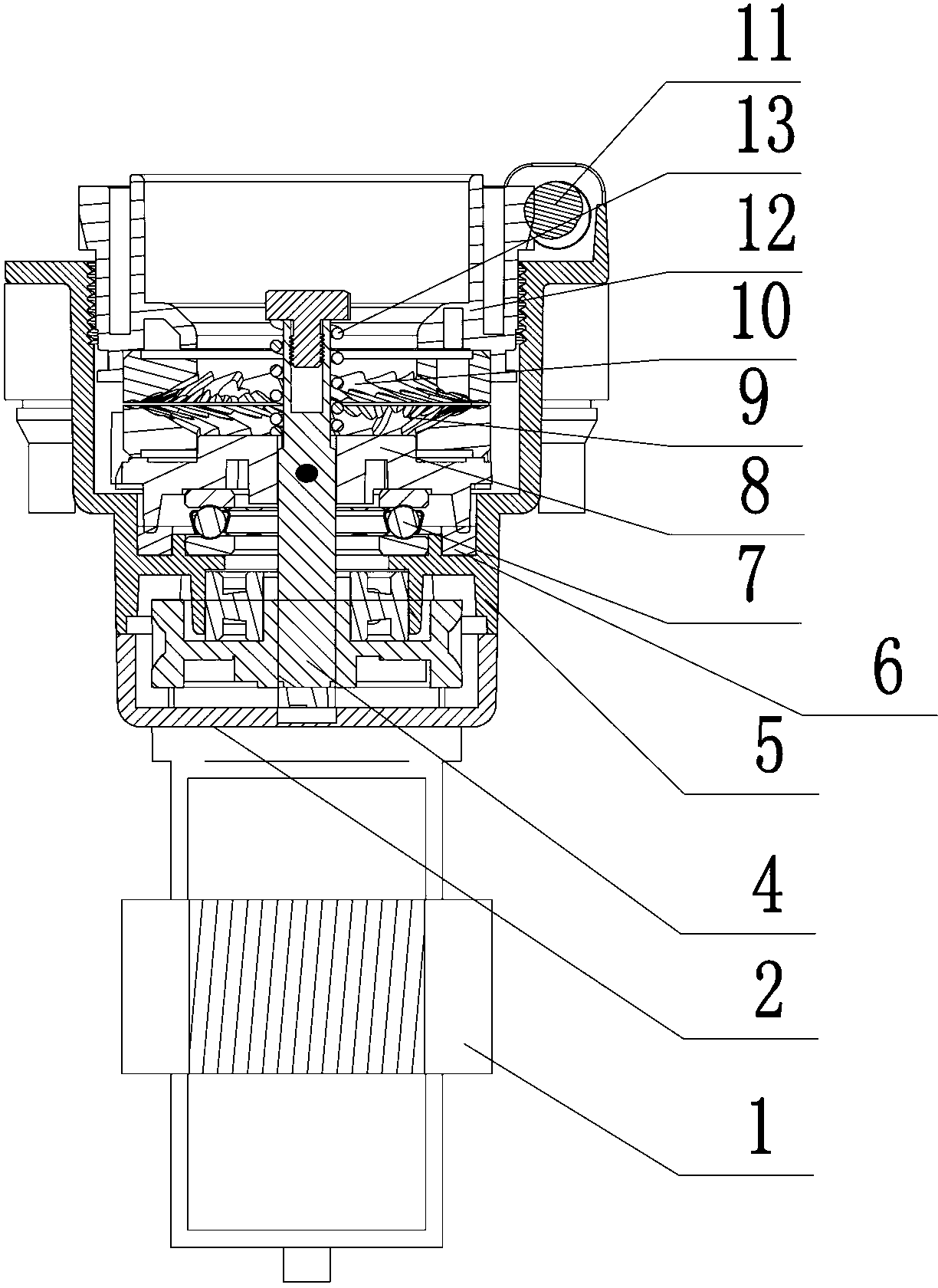

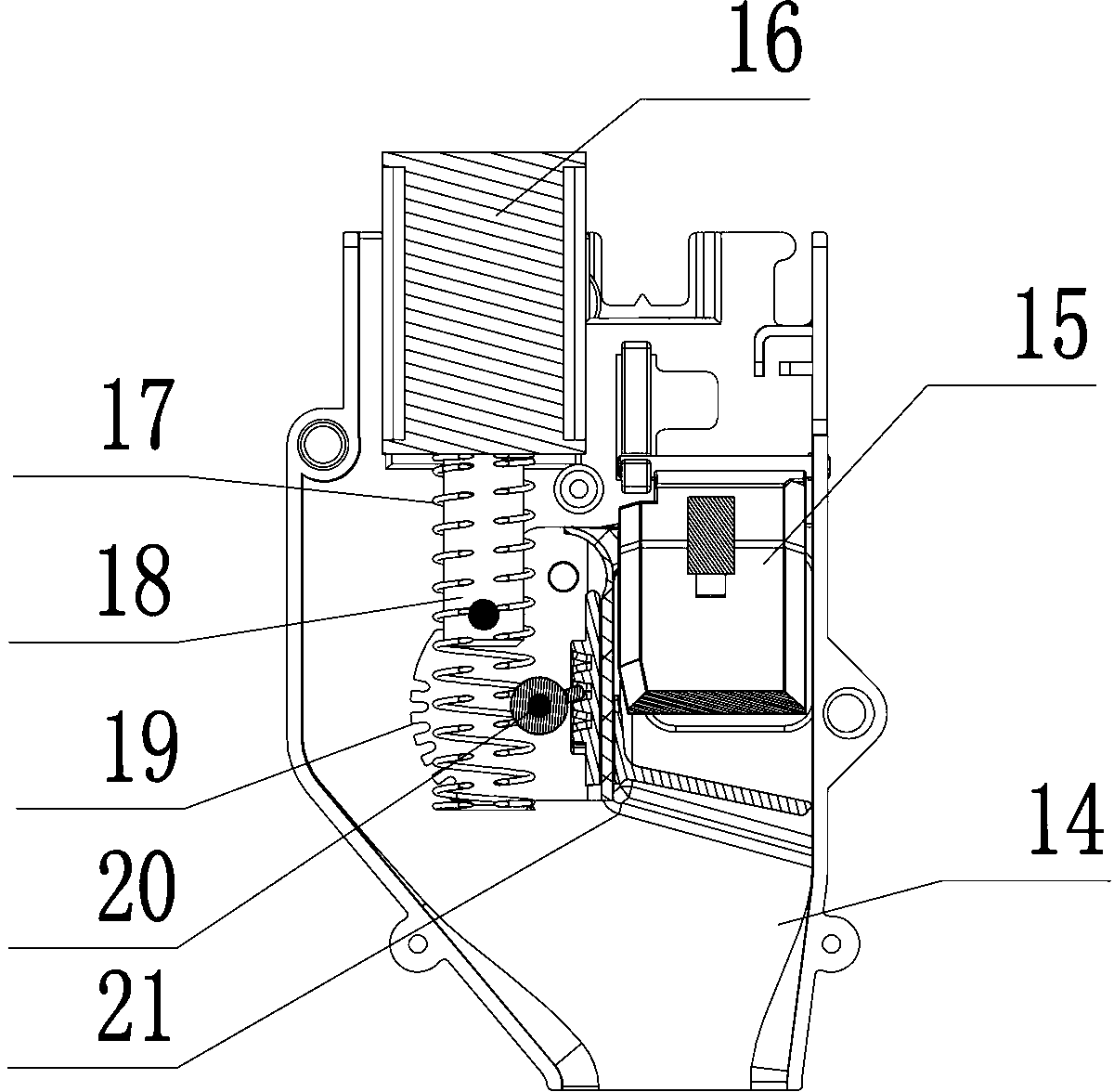

[0026] The bean grinding system of the fully automatic coffee machine includes a motor 1, a helical gear 4, a lower tool holder 8, a lower tool 9 and an upper tool 10.

[0027] The output end of the motor 1 is provided with a gear meshed with the helical gear 4 . The central axis of the helical gear 4 is clamped with the lower tool holder 8, the lower cutter 9 is fixedly arranged on the lower tool holder 8, the upper cutter 10 is fixedly arranged on the upper tool holder 12, the lower cutter 9 and the upper The cutter 10 is arranged coaxially.

[0028] When working, the motor 1 rotates, and the helical gear 4 is driven by the cylindrical twist gear arranged at the output end of the motor 1 to rotate. The helical gear 4 converts the high-speed rotation of the motor 1 into a low-speed rotation, and drives the lower tool holder 8 and the lower tool 9 to rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com