Meniscus gelatinizing device for single-sided gelatinizing of steel band tapes

A technology of gluing device and steel tape ruler, which is applied to the device for coating liquid on the surface, coating, etc., can solve the problems of poor uniformity of film thickness, harsh technical conditions, difficult implementation, etc., and achieve high utilization rate and recovery rate , Precise control of film thickness, good effect of coating and coating requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

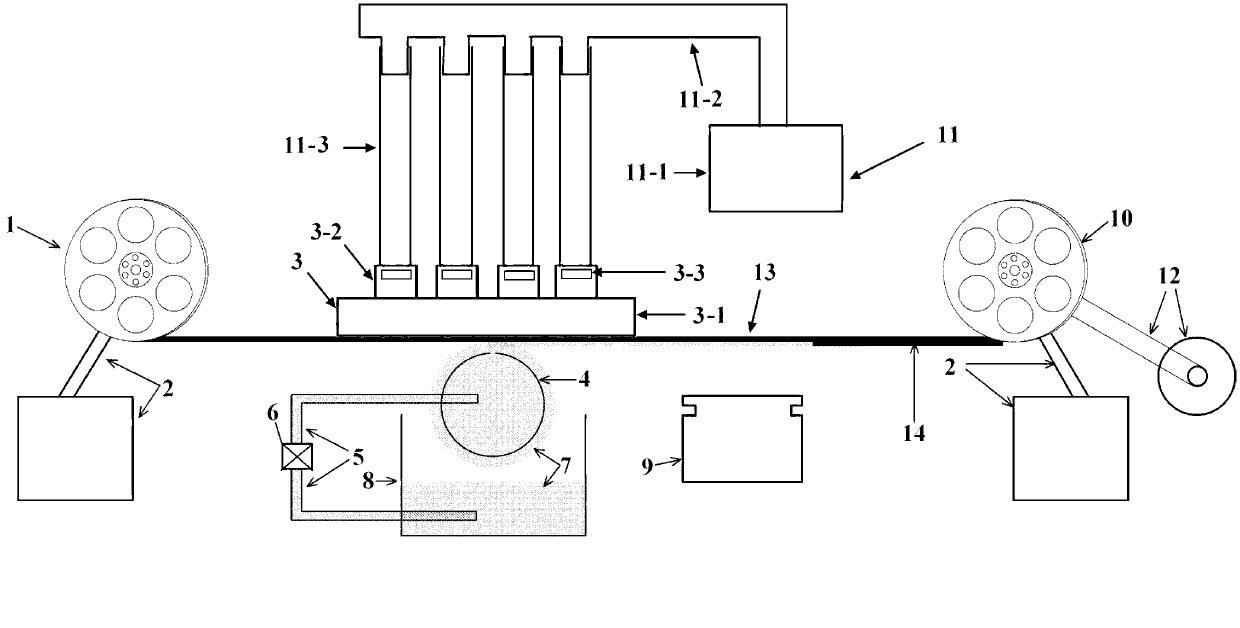

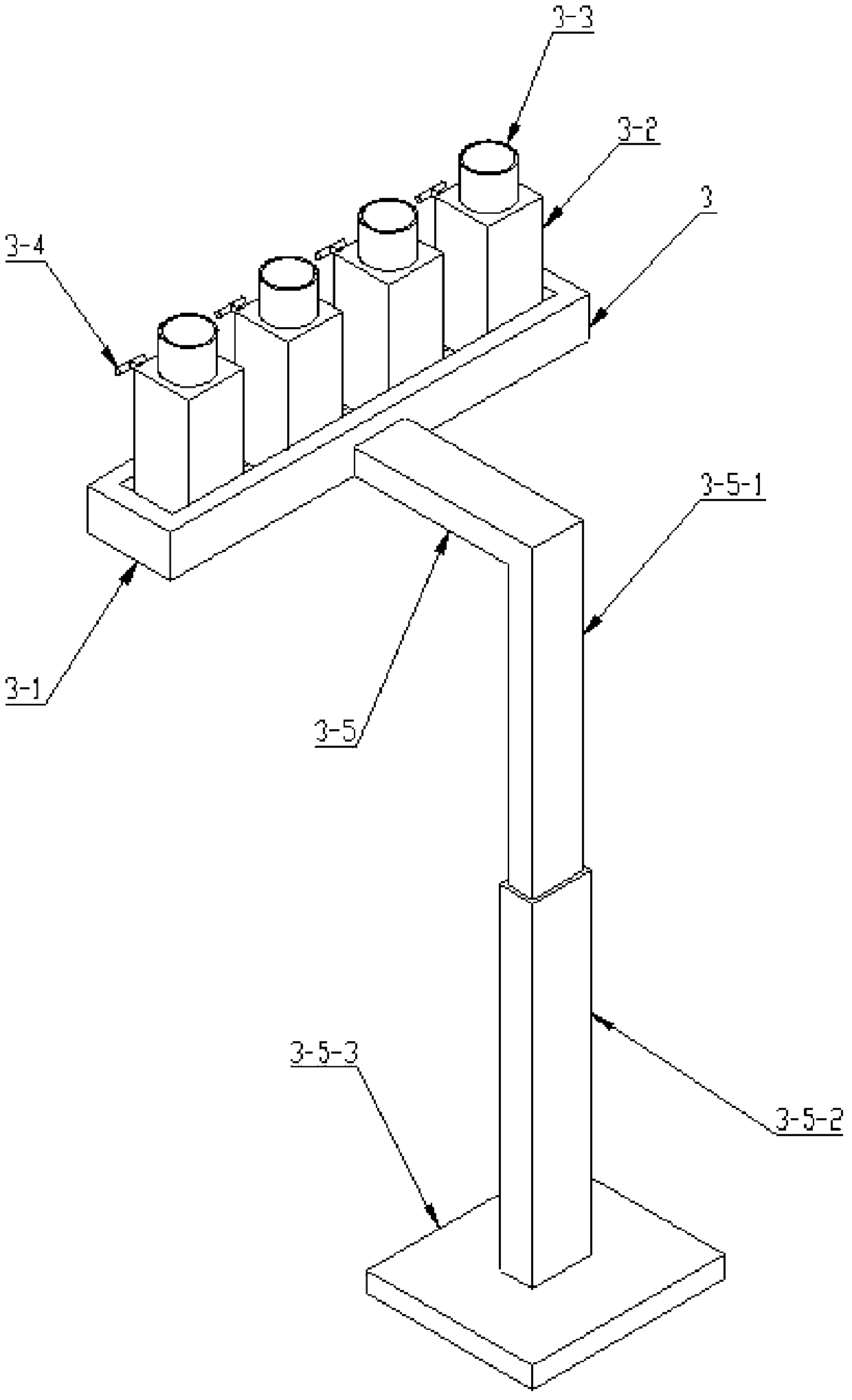

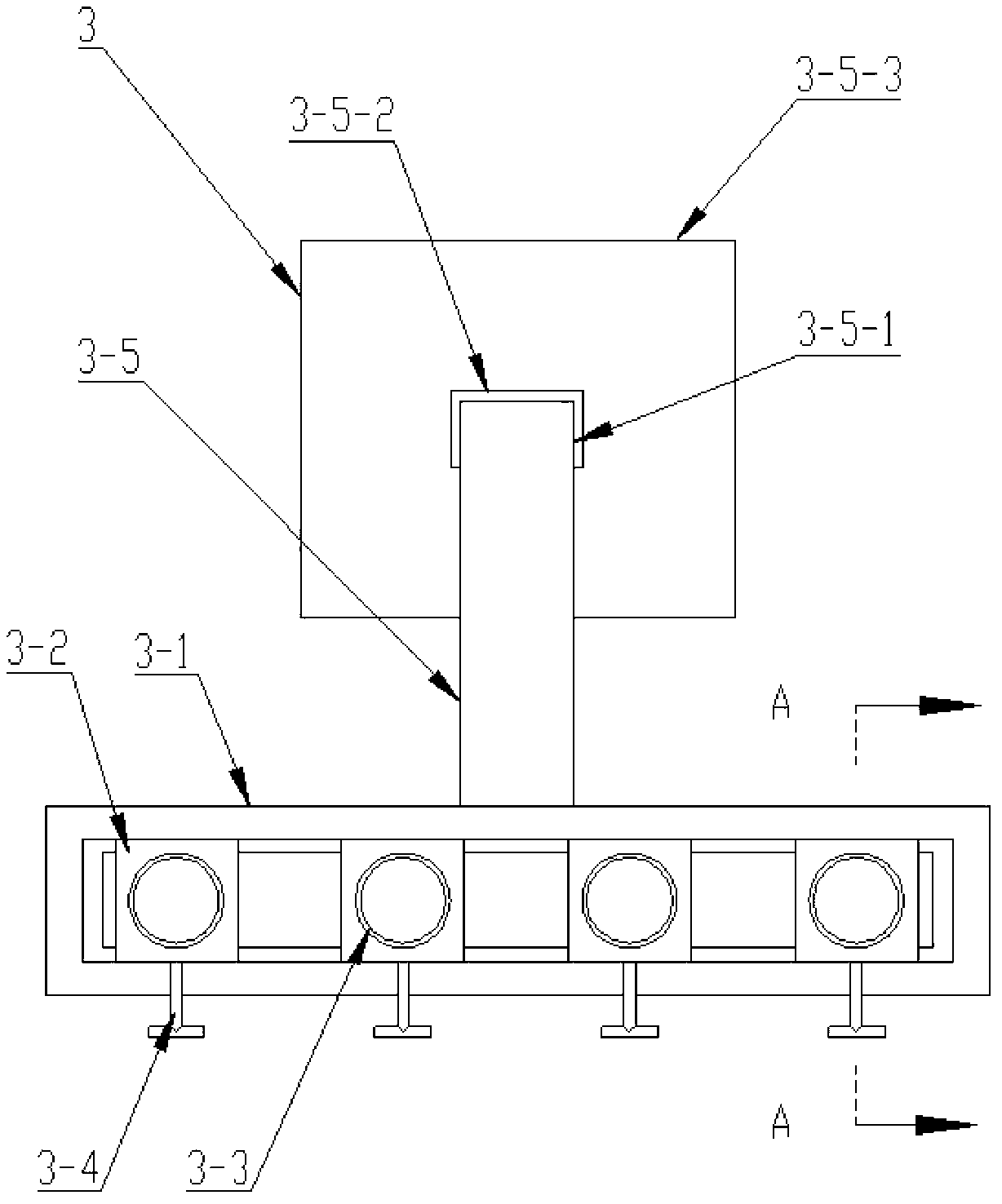

[0026] Such as Figure 1 to Figure 8 As shown, the meniscus gluing device for one-sided gluing of a steel tape ruler of the present invention includes a driven steel tape reel 1, two steel tape reel supports 2, a steel tape ruler horizontal positioning device 3, a slit plating rod 4. Rubber pipe 5, delivery pump 6, glue container 8, glue curing device 9, active steel belt reel 10, vacuum system 11 and transmission device 12, driven steel belt reel 1 and active steel belt reel 10 are relatively placed , the rotation axes of the two are parallel and are respectively fixed on the level ground by a steel belt reel support 2 below respectively, and the lower ends of the driven steel belt reel 1 and the driving steel belt reel 10 are all located on the steel belt running plane 13.

[0027] The slit plating rod 4 is located between the driven steel strip reel 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com