Adjusting mechanism for wire-arranging distance of wire-drawing machine

An adjusting mechanism and wire drawing machine technology are applied in the field of adjusting mechanism and wire drawing machine wire spacing adjusting mechanism, which can solve the problems of difficulty in meeting and low adjustment and control precision, and achieve a simple and compact structure, improve the adjustment and control precision, and improve the degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific drawings and embodiments.

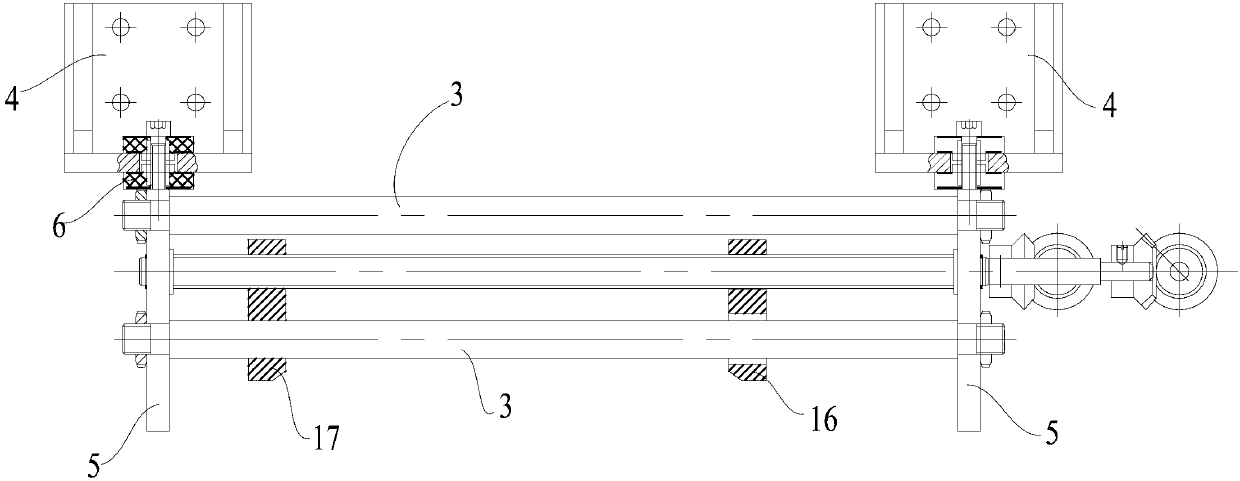

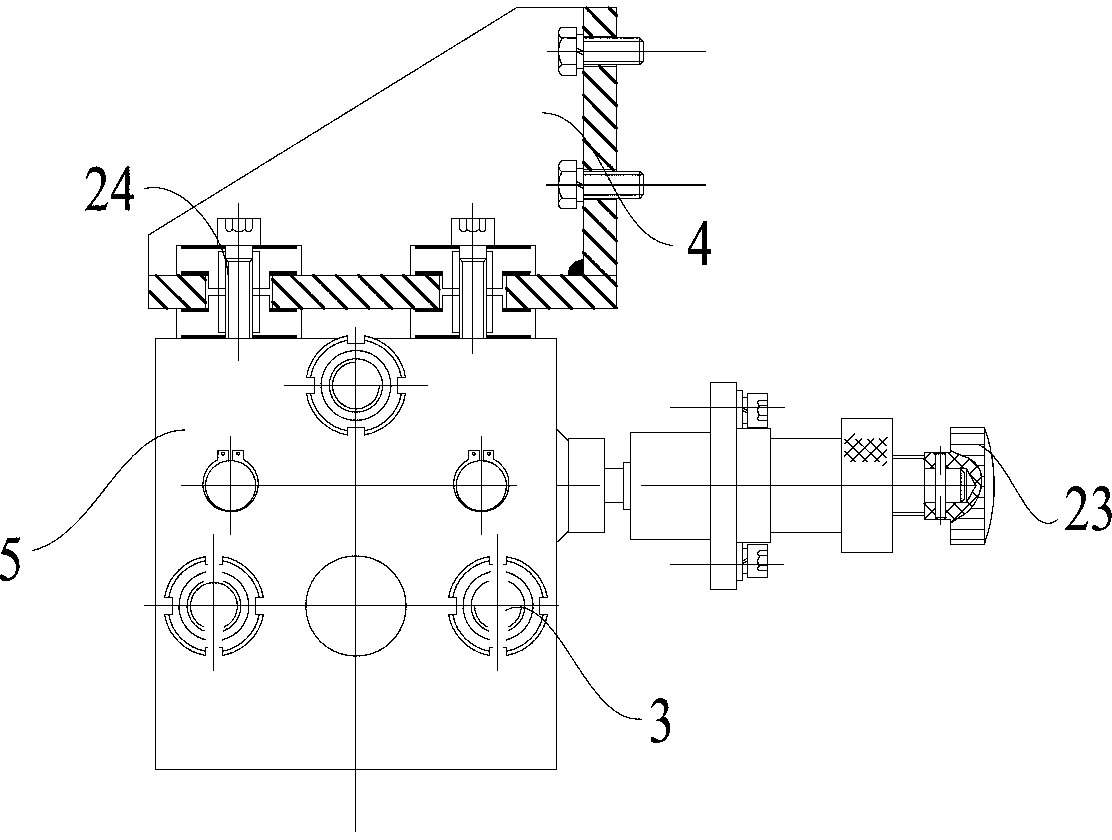

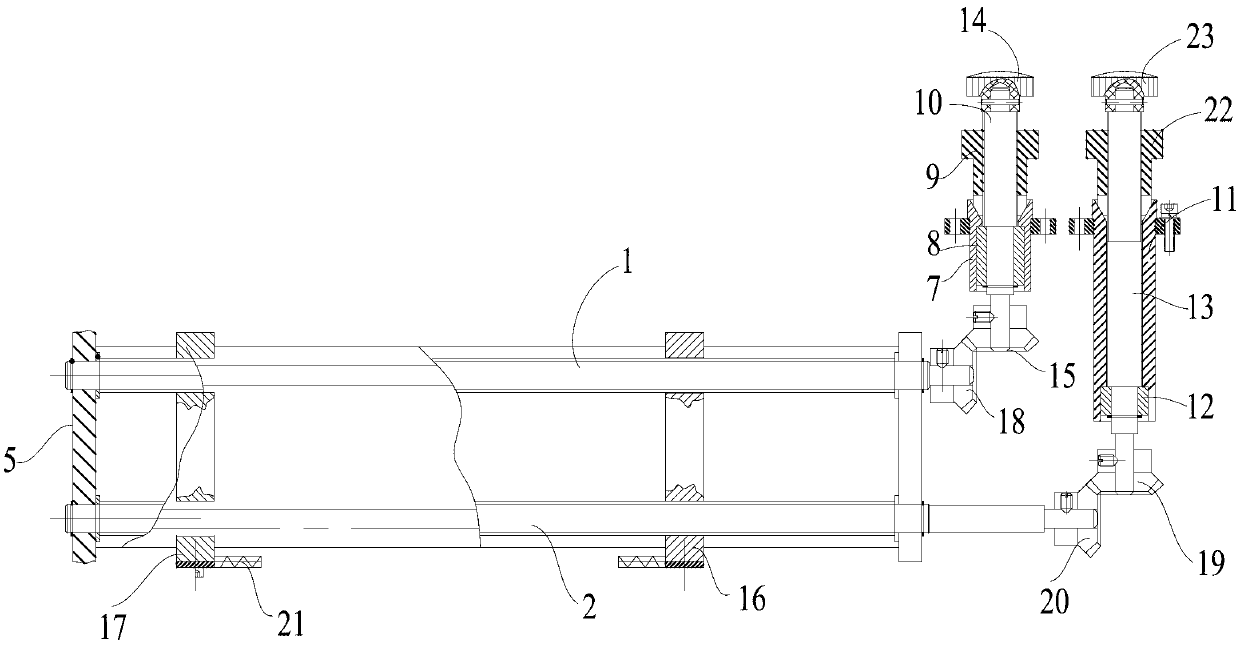

[0020] like figure 1 , figure 2 and image 3 As shown: In order to improve the adjustment requirements for the wire spacing of the wire drawing machine, the present invention includes an adjustment bracket, and the adjustment bracket is provided with a first thread adjustment rod 1 and a second thread adjustment rod 1 parallel to the first thread adjustment rod 1. Screw adjustment rod 2; the first screw adjustment rod 1 is screwed with a signal board 16, and the second screw adjustment rod 2 is screwed with a sensor board 17, and the sensor board 17 is provided with a cable corresponding to the signal board 16 Distance measuring sensor 21; one end of the first screw adjusting rod 1 is provided with a first screw adjusting mechanism, and one end of the second adjusting screw rod 2 is provided with a second screw adjusting mechanism.

[0021] Specifically, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com