Working device for extruding miniature thin-wall multi-hole flat pipes by using multiple-step tower-shaped fishtail type core rod

A working device and mandrel technology, which is applied to metal extrusion dies, manufacturing tools, metal processing equipment, etc., can solve problems such as welding difficulties and material flow filling difficulties, and achieve the effect of avoiding metal eddy currents and turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] one. Mold structure

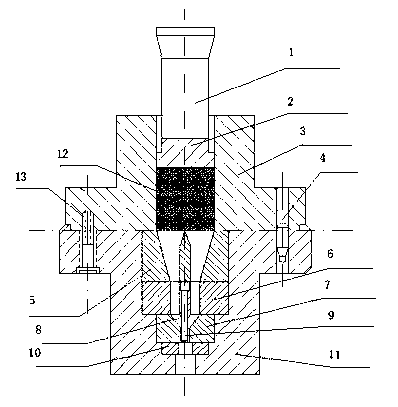

[0034] like figure 1 As shown, the working device of the thin-walled porous flat pipe of the multi-stage tower-shaped fishtail mandrel provided by the present invention includes the forming part of the mould, the fixing part and the pressurizing part.

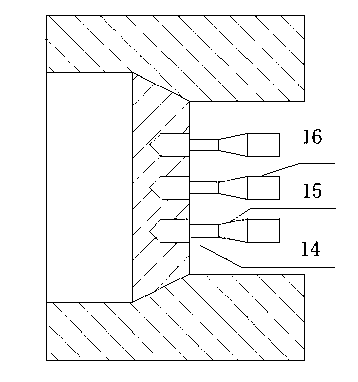

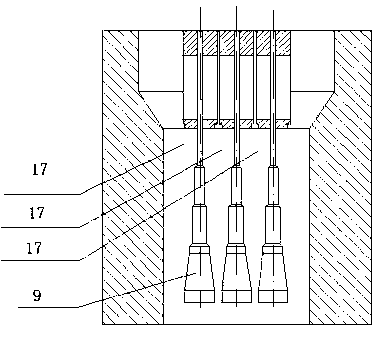

[0035] The molding part includes: splitter mold 5 , diversion mold 6 , welding mold 7 , mandrel 9 .

[0036] The fixed part includes: pin 4, extrusion barrel 3, support ring 10, die set 11, screw 13

[0037] The pressing part includes: extrusion shaft 1, extrusion pad 2.

[0038] The concrete structure of this mould is that in the mounting hole of mold case 11, place support ring 10, welding and mold 7, diversion die 6, and diversion die 5 successively, mandrel 9 is arranged in diversion die 6, the top of die case The extrusion cylinder 3 is fixed by the pin 4 and the screw 13, and the extrusion pad 2 and the extrusion shaft 1 are sequentially placed in the extrusion cylinder. The mandrel descr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com