Injection moulding machine control system based on function adapter line boxes with CPUs (central processing units)

A transfer junction box and control system technology, which is applied in the field of injection molding machine controllers, can solve the problems of easy interference in long-distance transmission of analog signals, large errors in electronic scale and temperature signals, and difficulty in guaranteeing the control accuracy of injection molding machines, etc., to achieve IO expansion Ease of use and the effect of reducing the number of cable connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

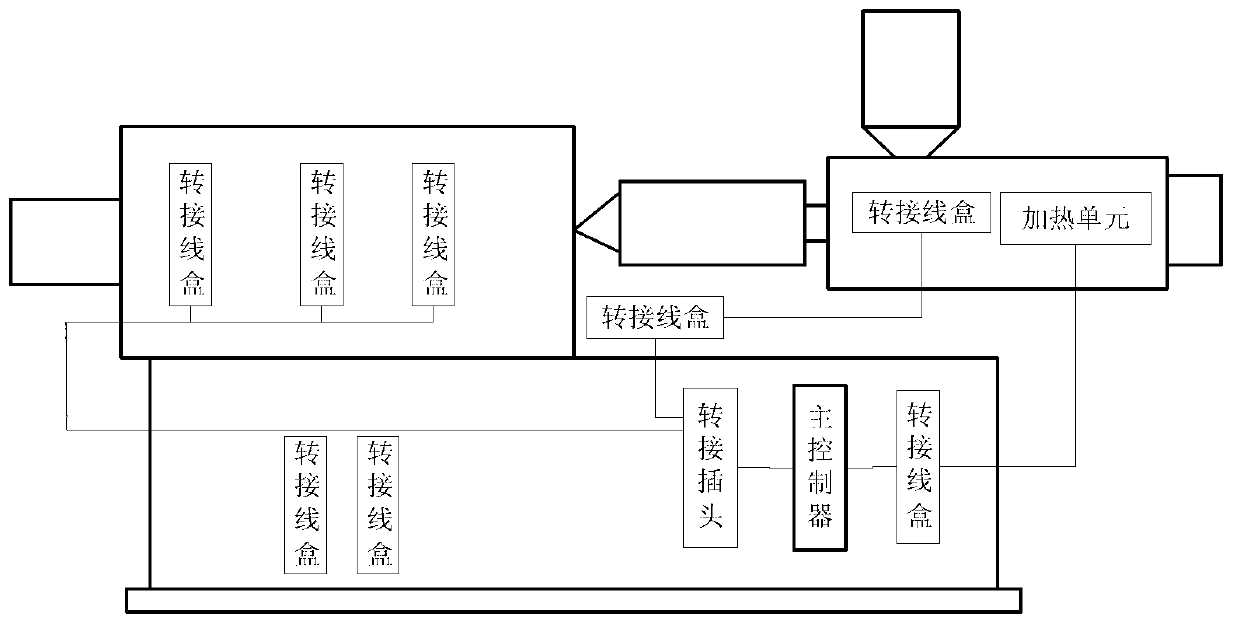

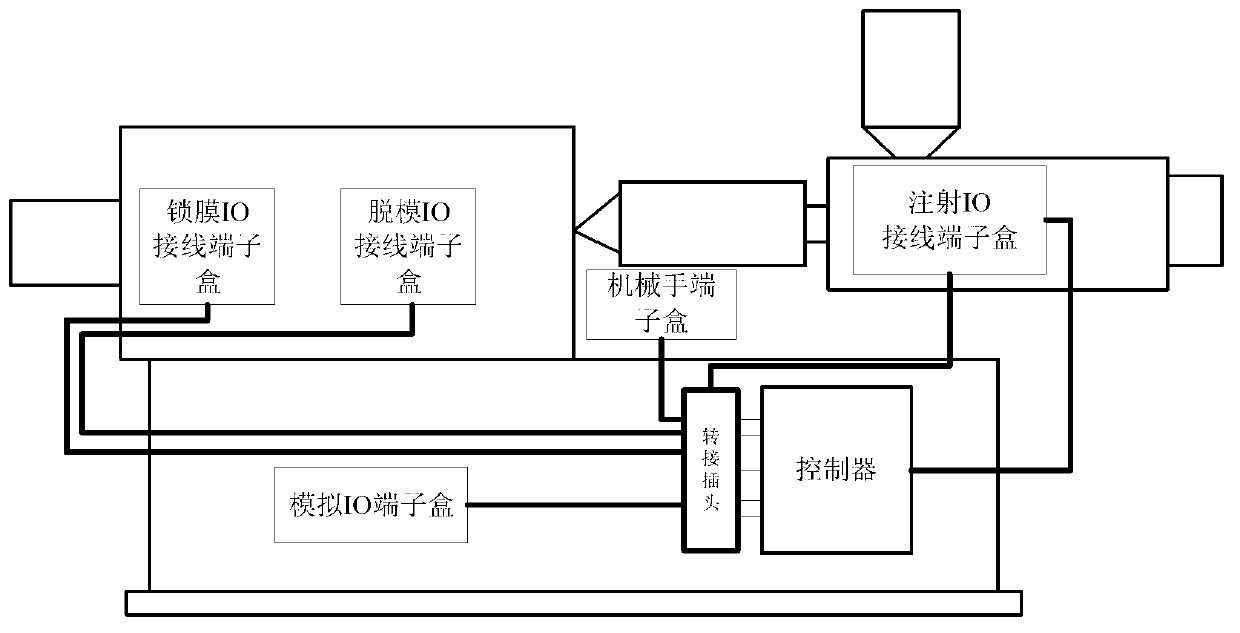

[0019] The present invention will be further described below with reference to the accompanying drawings.

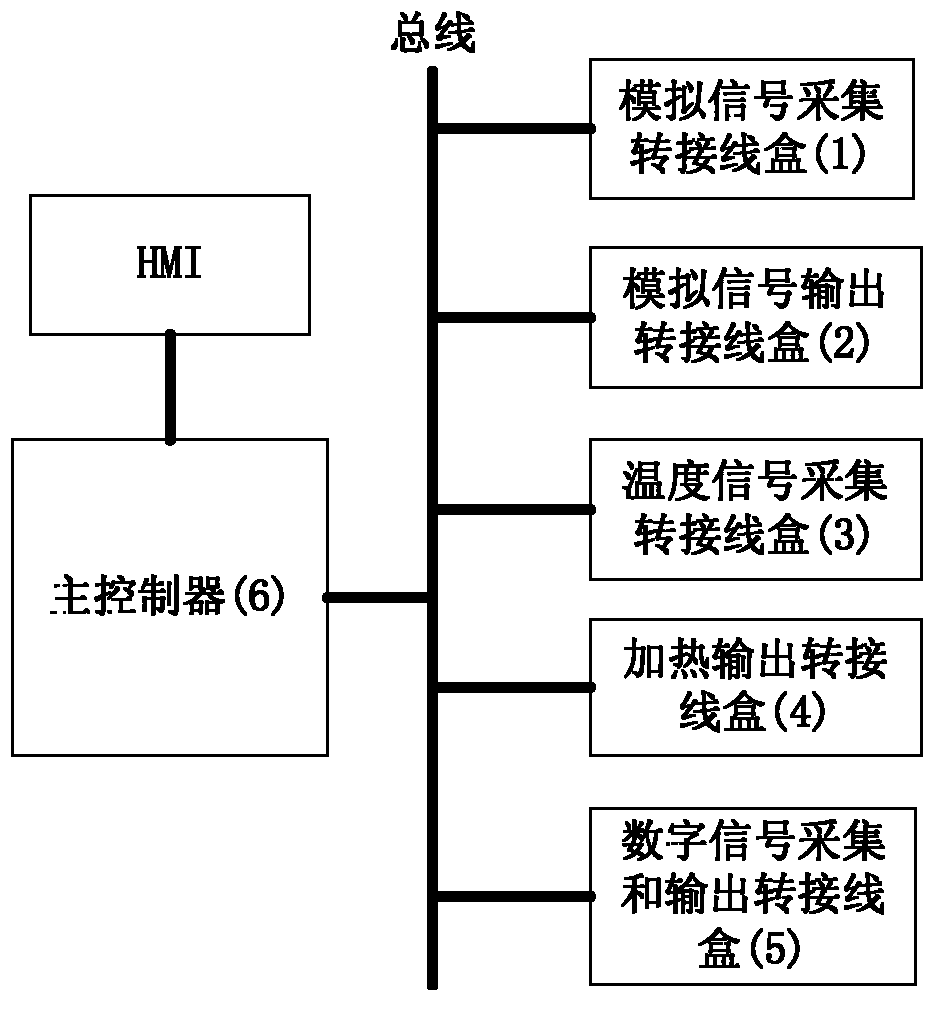

[0020] The injection molding machine control system with CPU transfer junction box according to the present invention has the composition principle as follows figure 2 As shown, the injection molding machine control system is composed of the main controller 6 and the function junction box with CPU, wherein the junction box is designed according to different functional purposes and different parameter requirements, and there are analog signal acquisition junction box 1, analog signal Output transfer junction box 2, temperature signal acquisition transfer junction box 3, heating output transfer junction box 4, digital signal acquisition and output transfer junction box 5, main controller 6 and transfer junction box through CAN bus (can be RS485, industrial Ethernet etc.), each type of junction box can be connected to the bus according to the needs, and the main controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com