Maintenance trolley driving mechanism

A technology of driving mechanism and trolley, which is applied in the direction of motor vehicles, vehicle parts, elastic suspension, etc., can solve the problems of increasing configuration and maintenance costs, falling steel slag, increasing resistance, etc., and achieves the reduction of operating costs in high temperature areas Danger, reduce configuration and maintenance costs, reduce the effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention relates to the field of metallurgy, especially when the ground space of the steel plant is relatively compact, the ladle car and the maintenance trolley in the RH vacuum refining device cannot share the same track to run, and at this time it is necessary to cross the tracks of the ladle car and the maintenance trolley Cross arrangement, in order to ensure that both vehicles can run normally, the invention adopts a new driving structure type of maintenance trolley, which solves the technical problem of difficult operation when the tracks meet.

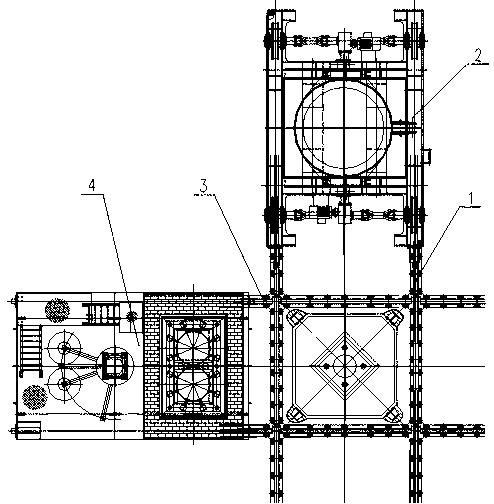

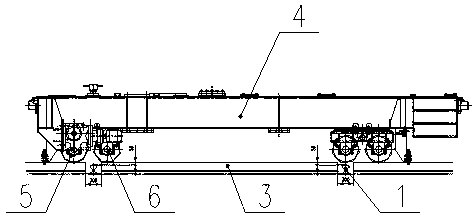

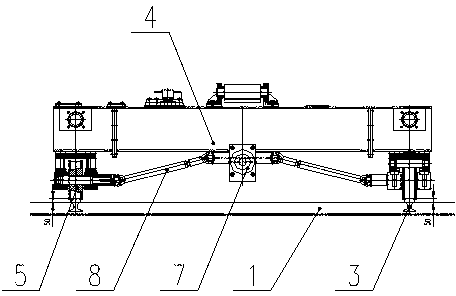

[0016] see Figure 1 to Figure 4 , the specific structure of a maintenance trolley drive mechanism involved in the present invention is:

[0017] Including driving wheel system 5, driven wheel system 6, driving system 7, universal coupling 8, wheel frame 9, connecting ear seat 10, disc spring 11 and steel pad 12; wherein,

[0018] The wheel frame 9 is hinged under the 4 girders of the main body of the maintenance t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com