Special air saving unit for pneumatic conveying and control system of special air saving unit

A control system and material conveying technology, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of low downstream pressure, waste, and increased conveying flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

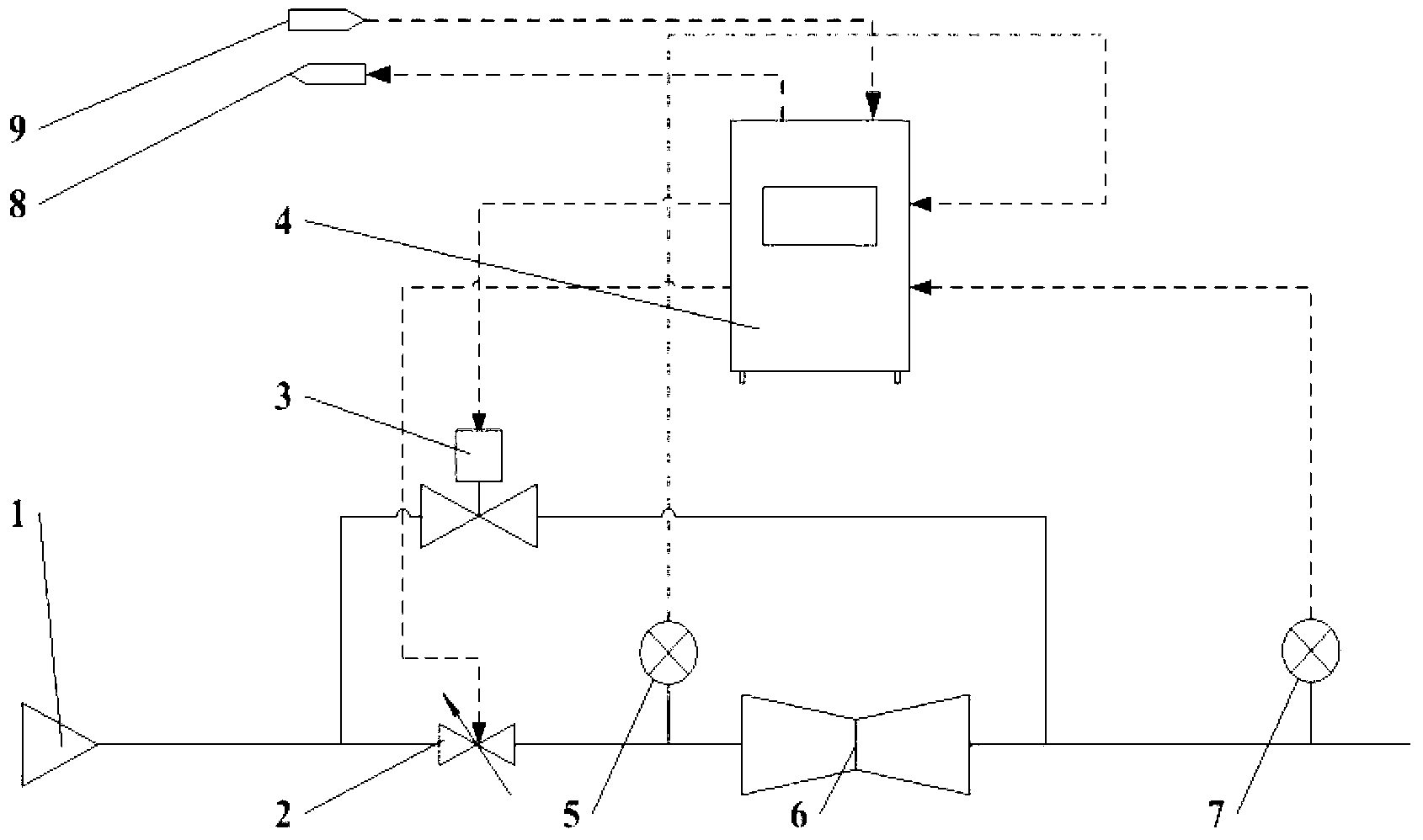

[0014] 1. The control unit has a touch screen, communicates with the main control PLC, displays the real-time curve of upstream and downstream pressure and valve opening feedback, and can set the opening and closing of each valve and program control parameters by touching the buttons.

[0015] 2. The control program is divided into manual state and automatic state. In the manual state, the valve action is manually operated through the touch screen. The opening of the main regulating valve (2) can be set and the opening value can be fed back; if the bypass valve (3) is an on-off valve, its switching value can be set and the on-off status can be fed back; if the bypass valve (3) is a regulating valve, Its opening can be set and the opening value can be fed back. When the material is conveyed, through the debugging of the valve in the manual state, you can know the upstream pressure range of the steady flow element (6) and the corresponding opening range of the regulating valve (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com