Easy-to-tear plastic film material and preparation technology thereof

A preparation process and technology of plastic film, applied in the field of easy-to-tear plastic film material and its preparation process, can solve the problems of difficult to tear and tear of plastic film, the retention of unfavorable indentations and creases, and achieve a wide range of applications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

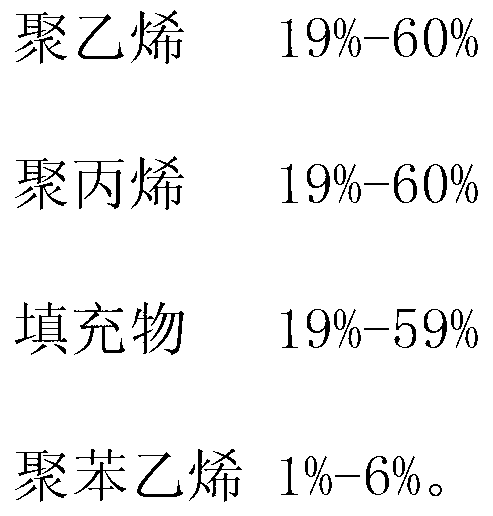

[0024] This embodiment provides an easy-to-tear plastic film material, comprising the following components by weight percentage:

[0025]

[0026] The filler is aragonite formed from natural minerals.

[0027] The preparation process of the above-mentioned easy-to-tear plastic film material is as follows:

[0028] (1) Mixing: Weigh 600kg of polyethylene, 190kg of polypropylene, 190kg of aragonite formed from natural minerals and 20kg of polystyrene to form a uniform mixture;

[0029] (2) Mixing: Use a twin-screw extruder to mix the mixture. During mixing, the temperature of the main engine is 230°C, the pressure of the barrel and the screw is 3MPa, and extrude to obtain a strip-shaped compound;

[0030] (3) Cooling: further cooling the strip-shaped kneaded material through the cooling water tank;

[0031] (4) Moisture removal: use a blower to remove the surface moisture of the cooled strip kneading material;

[0032] (5) Pelletizing: Pelletize the strip-shaped kneaded ma...

Embodiment 2

[0035] This embodiment provides an easy-to-tear plastic film material, comprising the following components by weight percentage:

[0036]

[0037] The filler is lignin.

[0038] The preparation process of the above-mentioned easy-to-tear plastic film material is as follows:

[0039] (1) Mixing: Weigh 190kg polyethylene, 600kg polypropylene, 200kg lignin and 10kg polystyrene to form a uniform mixture;

[0040] (2) Mixing: Use a twin-screw extruder to mix the mixture. When mixing, the temperature of the host machine is 210°C, the pressure of the barrel and the screw is 5MPa, and extrude to obtain a strip-shaped compound;

[0041] (3) Cooling: further cooling the strip-shaped kneaded material through the cooling water tank;

[0042] (4) Moisture removal: use a blower to remove the surface moisture of the cooled strip kneading material;

[0043] (5) Pelletizing: Pelletize the strip-shaped kneaded material after removing water to obtain the easy-to-tear plastic film material ...

Embodiment 3

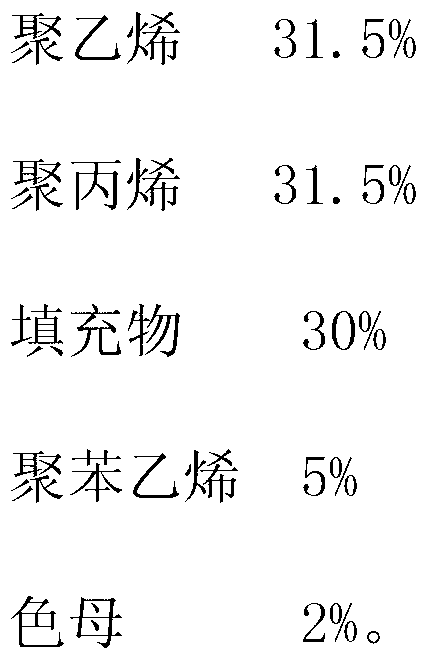

[0046] This embodiment provides an easy-to-tear plastic film material, comprising the following components by weight percentage:

[0047]

[0048] The filler is analcime.

[0049] The preparation process of the above-mentioned easy-to-tear plastic film material is as follows:

[0050] (1) Mixing: Weigh 310kg polyethylene, 300kg polypropylene, 300kg analcime, 40kg polystyrene and 50kg color masterbatch to form a uniform mixture;

[0051] (2) Mixing: Use a twin-screw extruder to mix the mixture. During mixing, the temperature of the host machine is 180°C, the pressure of the barrel and the screw is 3MPa, and extrude to obtain a strip-shaped compound;

[0052] (3) Cooling: further cooling the strip-shaped kneaded material through the cooling water tank;

[0053] (4) Moisture removal: use a blower to remove the surface moisture of the cooled strip kneading material;

[0054] (5) Pelletizing: Pelletize the strip-shaped kneaded material after removing water to obtain the easy-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com