Preparation method of polymer-stabilized liquid crystal thin film material with wide wave reflection

A technology for stabilizing liquid crystals and thin film materials, applied in the direction of liquid crystal materials, chemical instruments and methods, instruments, etc., can solve problems such as unfavorable operation control, strict mixing of liquid crystals, etc., achieve simplified production process, broadened reflection wave width, and wide application value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] First, clean the ITO glass, make a liquid crystal cell with a thickness of 10 μm whose inner surface has been processed by parallel rubbing orientation, and set aside;

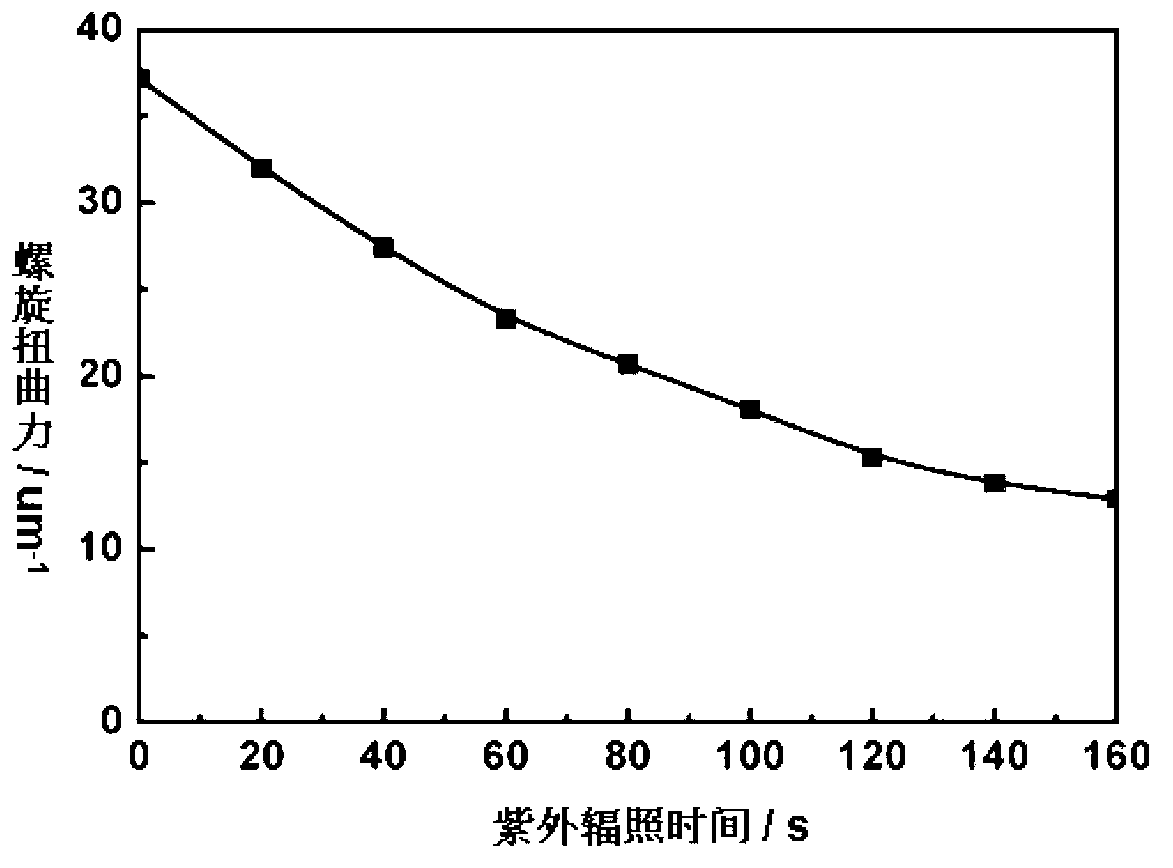

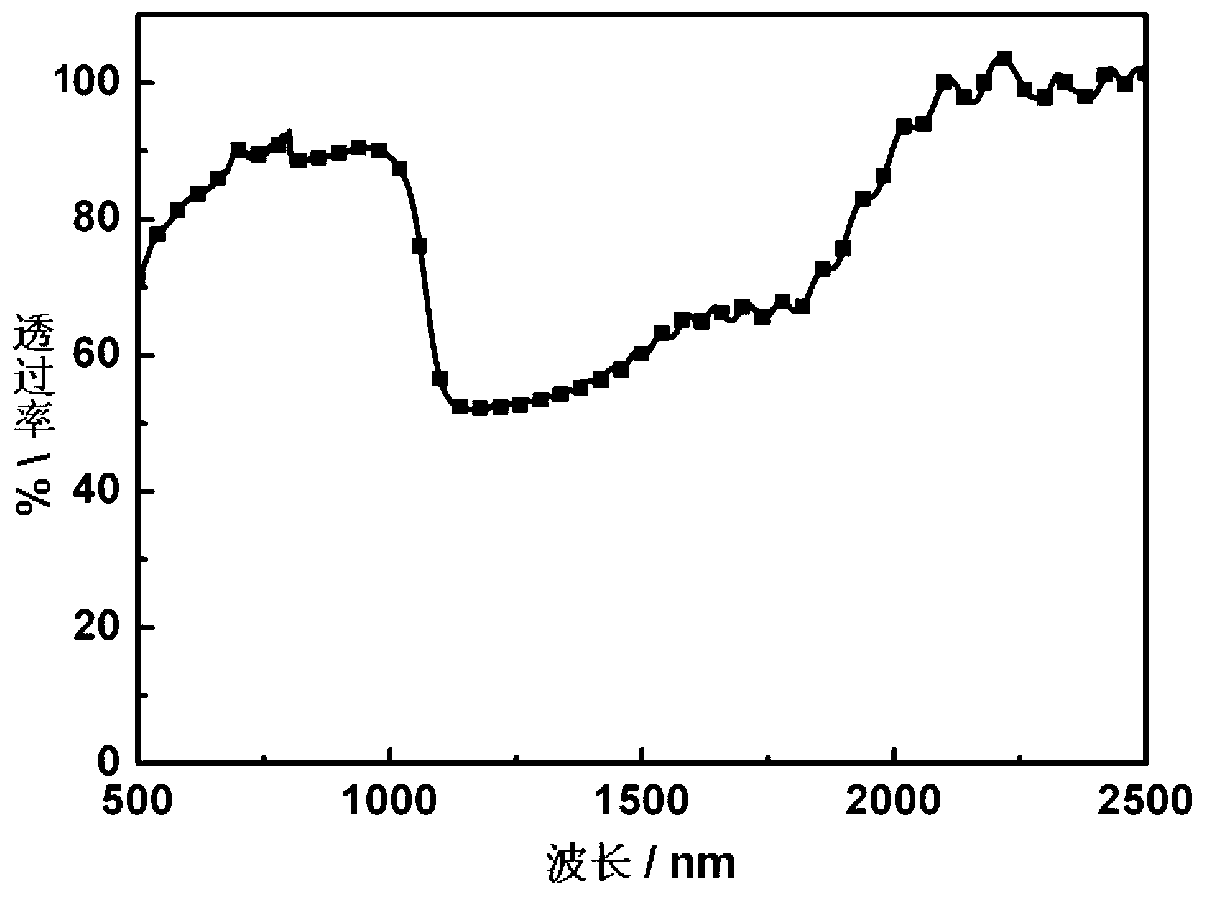

[0049] According to the mass percentage, the composite system of liquid crystal polymerizable monomer C6M / chiral compound S811 / small molecule nematic liquid crystal SLC1717 / photoinitiator 651 / azo chiral compound 2C is 15.00wt% / 9.20wt% / 75.00wt% / 0.40wt% / 0.40wt% were blended to obtain a liquid crystal composite system with a wide N* phase temperature range. In the liquid crystal cell, obtain the corresponding thin film material sample, and then use ultraviolet light under the condition of 40°C (the intensity of ultraviolet light is 1mw / cm 2 , the wavelength of ultraviolet light is 365nm) after irradiating for 30 minutes, the mixed liquid crystal system is polymerized to form a polymer network, and a liquid crystal film material with broadband reflection is obtained. The obtained liquid crystal thin film ...

Embodiment 2

[0060] First, clean the ITO glass, make a liquid crystal cell with a thickness of 10 μm whose inner surface has been processed by parallel rubbing orientation, and set aside;

[0061] According to the mass percentage, the composite system of the raw material liquid crystal polymerizable monomer C6M / chiral compound S811 / small molecule nematic liquid crystal SLC1717 / photoinitiator 651 / azo chiral compound 2C is 15.00wt% / 9.00wt according to the mass ratio % / 75.00wt% / 0.40wt% / 0.60wt% for blending to obtain a liquid crystal composite system with a wide N* phase temperature range. In the oriented liquid crystal cell, obtain the corresponding thin film material sample, and then use ultraviolet light under the condition of 40 ℃ (the intensity of the ultraviolet light is 3mw / cm 2 , the wavelength of the ultraviolet light is 365nm) after irradiating for 30 minutes, the mixed liquid crystal system is polymerized to form a polymer network, and a liquid crystal film material with broad-wave ...

Embodiment 3

[0063] First, clean the ITO glass, make a liquid crystal cell with a thickness of 10 μm whose inner surface has been processed by parallel rubbing orientation, and set aside;

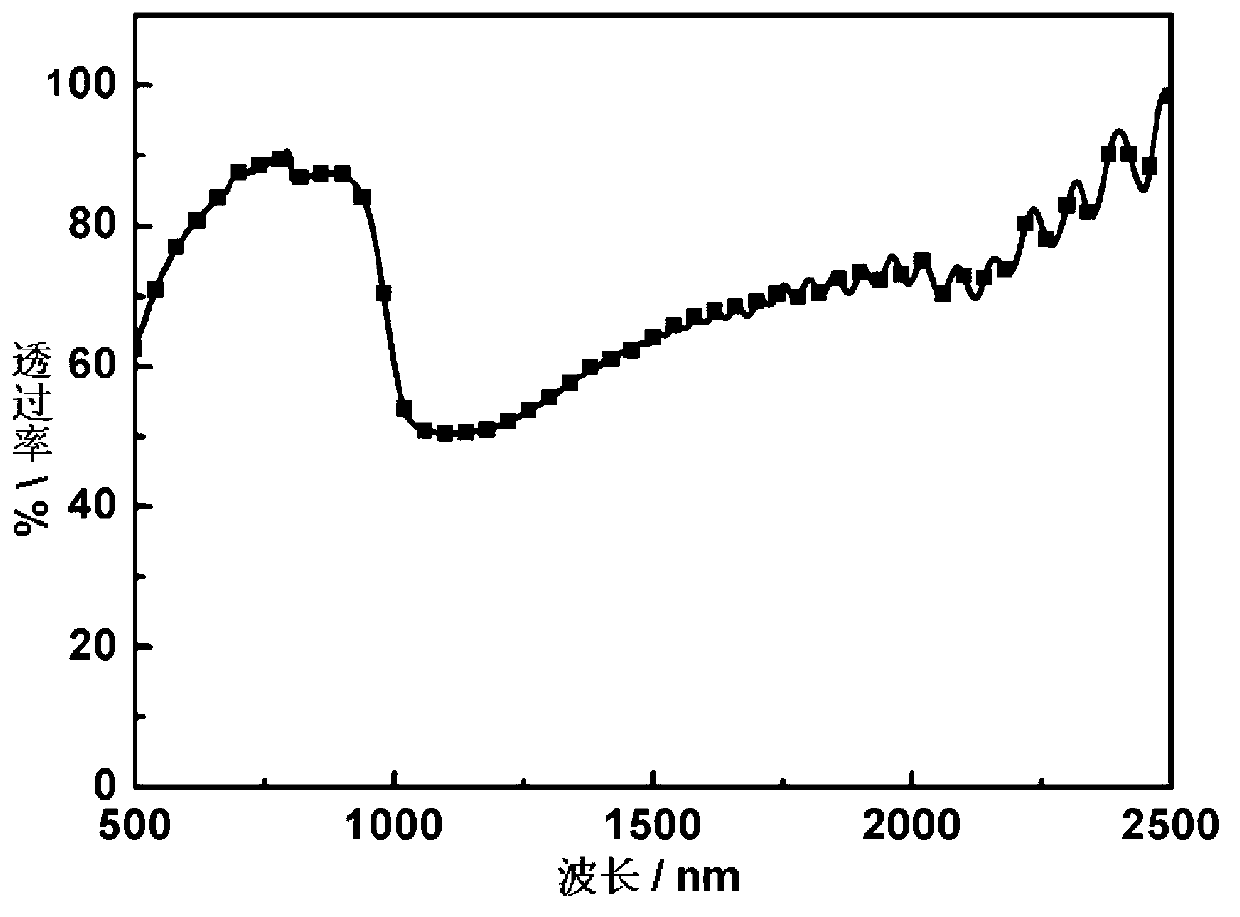

[0064] According to mass percentage, weigh 85wt% nematic liquid crystal SLC1717, 5.0wt% chiral compound R811, 8.0wt% liquid crystal polymerizable monomer, 1.5wt% azo chiral compound and 0.5wt% light The initiator benzophenone is blended to obtain a liquid crystal composite system with a wide N* phase temperature range. First, the liquid crystal composite system is poured into the above-mentioned liquid crystal cell that has undergone surface-parallel rubbing orientation at 100 ° C to obtain Corresponding film material samples, and then use ultraviolet light under the condition of 45 ℃ (the intensity of the ultraviolet light is 1μw / cm 2 , the wavelength of the ultraviolet light is 365nm) after irradiating for 1 hour, the mixed liquid crystal system is polymerized to form a polymer network, and a liquid c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com