Magnetorheological fluid

A technology of magnetorheological fluid and carbonyl iron powder, which is applied in the petroleum industry, lubricating compositions, etc., can solve the problems of not optimal shear yield stress and not optimal adjustability of shear yield stress, etc., and achieve good resistance Settling and anti-agglomeration properties, improved stability, and improved shear yield stress effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

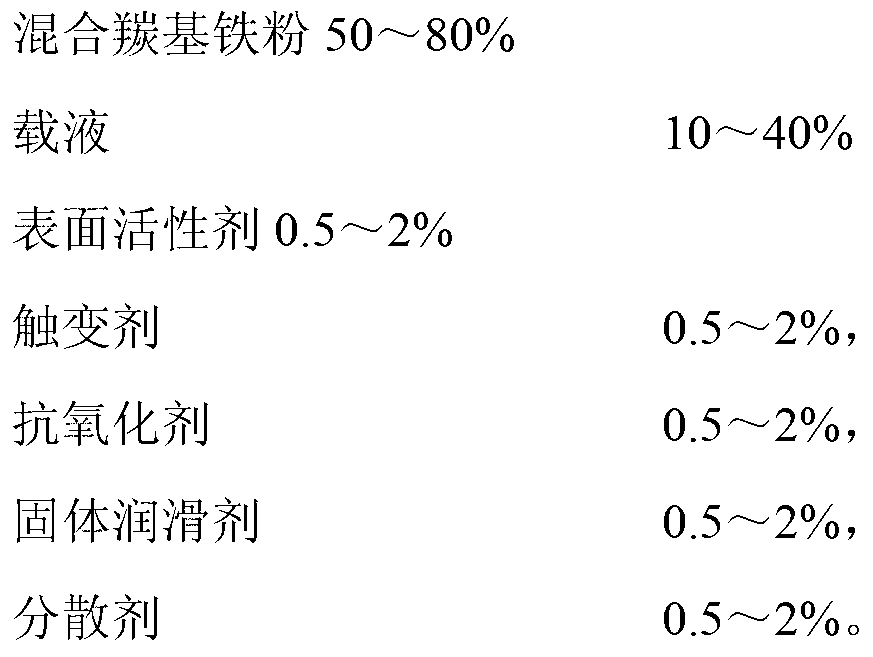

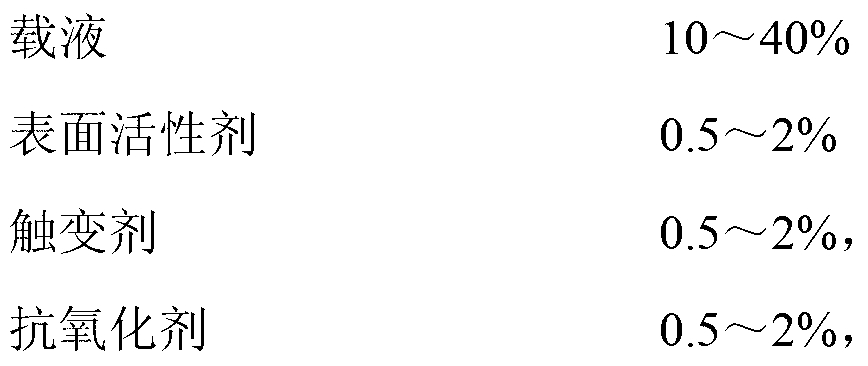

[0024] Mix 225 grams of surface-treated micron-scale carbonyl iron powder and 45 grams of nano-scale carbonyl iron powder, add the mixed carbonyl iron powder to 33.75 grams of methyl silicone oil, stir for 2 hours; then add 6.75 grams of surfactant N , N'-sodium diethylsulfonate, stirred for 1h; then added 6.75 grams of dispersant oleic acid, stirred for 1 hour; then added 6.75 grams of solid lubricant graphite, stirred for 2 hours; then added 6.75 grams of thixotropic agent organic bentonite, stirred 2h; finally add 6.75 grams of antioxidant dibutylhydroxytoluene, stir for 2h; put the stirred mixture into a ball mill and stir for 4h to obtain the magnetorheological fluid of the present invention, each component in the obtained magnetorheological fluid The weight percentage is: mixed carbonyl iron powder 80%, carrier liquid 10%, N, N'-sodium diethylsulfonate 2%, oleic acid 2%, graphite 2%, organic bentonite 2%, dibutyl hydroxytoluene 2%.

[0025] After standing for 1 year, th...

Embodiment 2

[0027] Mix 220 grams of surface-treated micron-scale carbonyl iron powder and 11 grams of nano-scale carbonyl iron powder, add the mixed carbonyl iron powder to 184.8 grams of vegetable oil, stir for 2 hours, and then add 9.24 grams of surfactant N, N '-Sodium diethylsulfonate, stirred for 1 hour; then added 9.24 grams of dispersant oleic acid, stirred for 1 hour; then added 9.24 grams of solid lubricant graphite, stirred for 2 hours; then added 9.24 grams of thixotropic agent organic bentonite, stirred for 2 hours Finally, add 9.24 grams of antioxidant dibutyl hydroxytoluene, stir for 2h; put the mixed material that has been stirred into a ball mill and stir for 4h to obtain the magnetorheological fluid of the present invention. The weight percentage is: mixed carbonyl iron powder 50%, carrier liquid 40%, N, N'-sodium diethylsulfonate 2%, oleic acid 2%, graphite 2%, organic bentonite 2%, dibutylhydroxytoluene 2% %.

[0028] After standing for one year, the magnetorheological...

Embodiment 3

[0030] Mix 350 grams of surface-treated micron-scale carbonyl iron powder and 70 grams of nano-scale carbonyl iron powder, add the mixed carbonyl iron powder to 165 grams of vegetable oil, stir for 2 hours, and then add 3 grams of surfactant N, N '-Sodium diethylsulfonate, stirred for 1 hour; then added 3 grams of dispersant oleic acid, stirred for 1 hour; then added 3 grams of solid lubricant graphite, stirred for 2 hours; then added 3 grams of thixotropic agent organic bentonite, stirred for 2 hours Finally, add 3 grams of antioxidant dibutyl hydroxytoluene, stir for 2h; put the mixed material that has been stirred into a ball mill and stir for 4h to obtain the magnetorheological fluid of the present invention. The weight percentage is: mixed carbonyl iron powder 70%, carrier liquid 27.5%, N, N'-sodium diethylsulfonate 0.5%, oleic acid 0.5%, graphite 0.5%, organic bentonite 0.5%, dibutylhydroxytoluene 0.5% %.

[0031] After standing for 1 year, the magnetorheological fluid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com