Light fermentation hydrogen production reactor

A reactor and photo-fermentation technology, applied in the field of photo-fermentation hydrogen production reactors, can solve the problems of large dead space inside the hydrogen production reactor, difficult to control reaction temperature, uneven liquid mixing, etc., so as to improve the hydrogen production capacity of photo-fermentation. , the structure is simple, the effect of improving the conversion rate of light energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

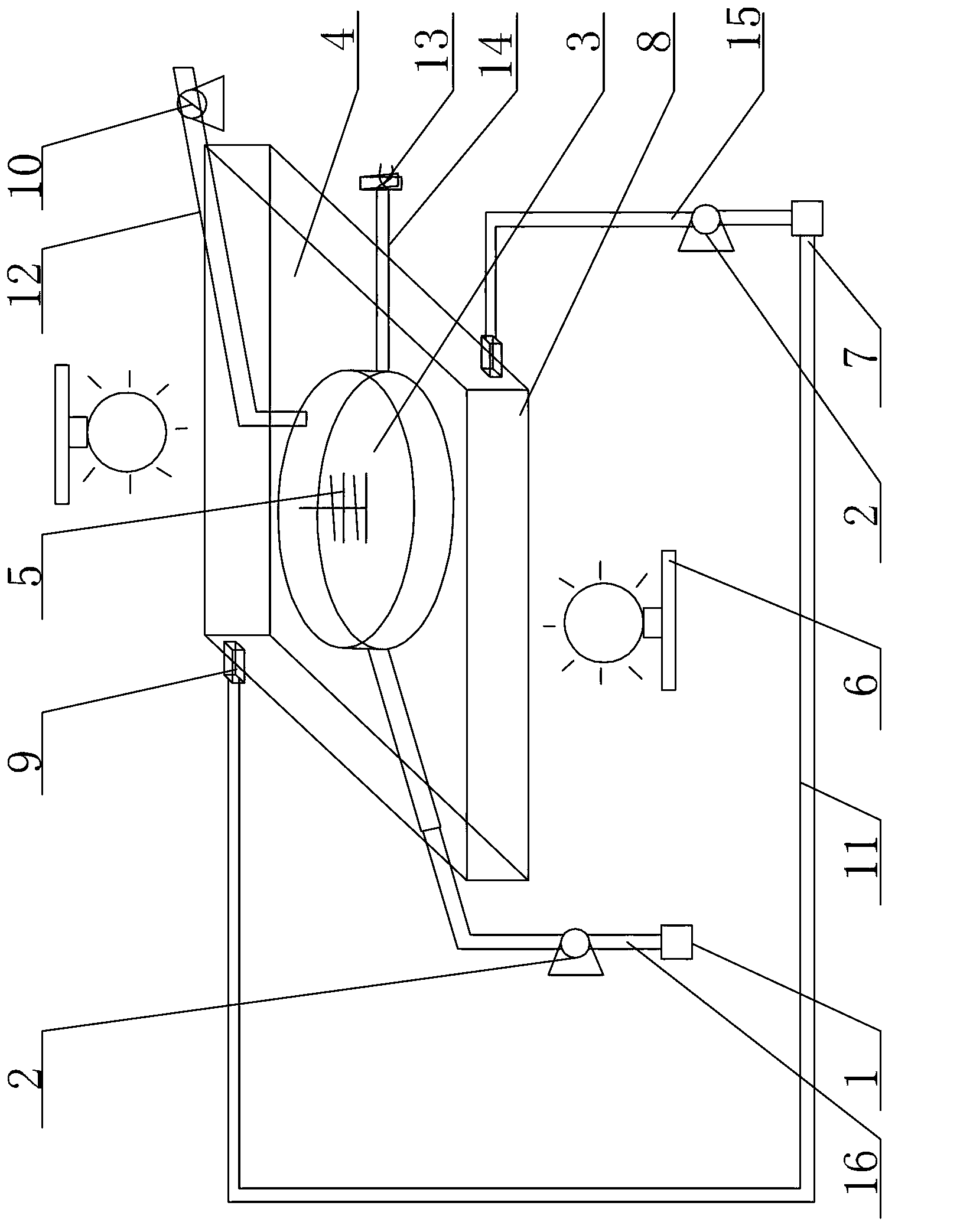

[0009] Specific implementation mode one: combine figure 1 Describe a photofermentation hydrogen production reactor in this embodiment, the reactor includes a culture medium storage tank 1, a stirring paddle mechanism 5, a water bath 7, a reactor shell 8, a third delivery pipe 11, a gas discharge pipe 12, A reaction liquid outlet pipe 14, a first delivery pipe 15, a second delivery pipe 16, two liquid inlet pumps 2 and two lighting mechanisms 6;

[0010] The reactor housing 8 is provided with an annular partition wall, which divides the reactor housing 8 into the reactor reaction zone 3 and the reactor water bath zone 4, and the stirring paddle mechanism 5 is arranged in the reactor reaction zone 3, and the second One end of the delivery pipe 16, one end of the gas discharge pipe 12 and one end of the reaction liquid outlet pipe 14 are all communicated with the reactor reaction zone 3, and the other end of the second delivery pipe 16 is communicated with the culture medium stor...

specific Embodiment approach 2

[0011] Specific implementation mode two: combination figure 1 This embodiment describes a photofermentation hydrogen production reactor, the reactor also includes a gas flow meter 10, the gas flow meter 10 is arranged at the outlet end of the gas discharge pipe 12, and the other is the same as the first embodiment.

specific Embodiment approach 3

[0012] Specific implementation mode three: combination figure 1 This embodiment describes a photofermentation hydrogen production reactor, the reactor also includes a clamp 13, the clamp 13 is arranged at the outlet end of the reaction liquid outlet pipe 14, and the other is the same as the first embodiment.

[0013] Specific implementation mode four: combination figure 1 Describe a photofermentation hydrogen production reactor in this embodiment, the reactor also includes two joints 9, the joint 9 is provided at the connection between the third delivery pipe 11 and the reactor water bath area 4, the first delivery pipe 15 and the reactor A joint 9 is provided at the junction of the water bath area 4, and the others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com