Novel gas diversion supporting device for hydrogen extraction adsorption tower

A technology of a support device and an adsorption tower, which is applied in the field of a gas diversion support device for a new type of hydrogen extraction adsorption tower, can solve the problems that the support ring endangers the safety of equipment operation, affects the safe operation of program-controlled valves, and has a large dead space at the bottom. The stability and distribution uniformity are strong, the structure is simple and reliable, and the dead space is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The schematic embodiments and descriptions of the present invention are used to explain the present invention, but are not intended to limit the present invention.

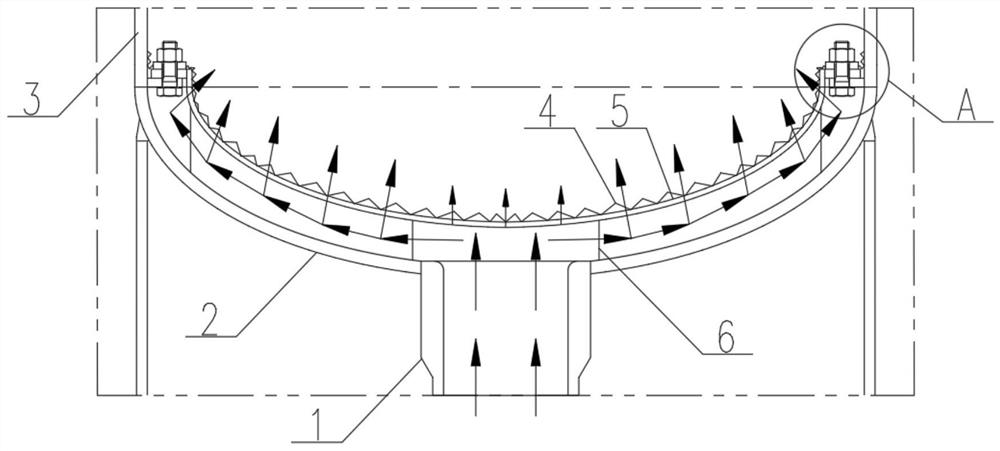

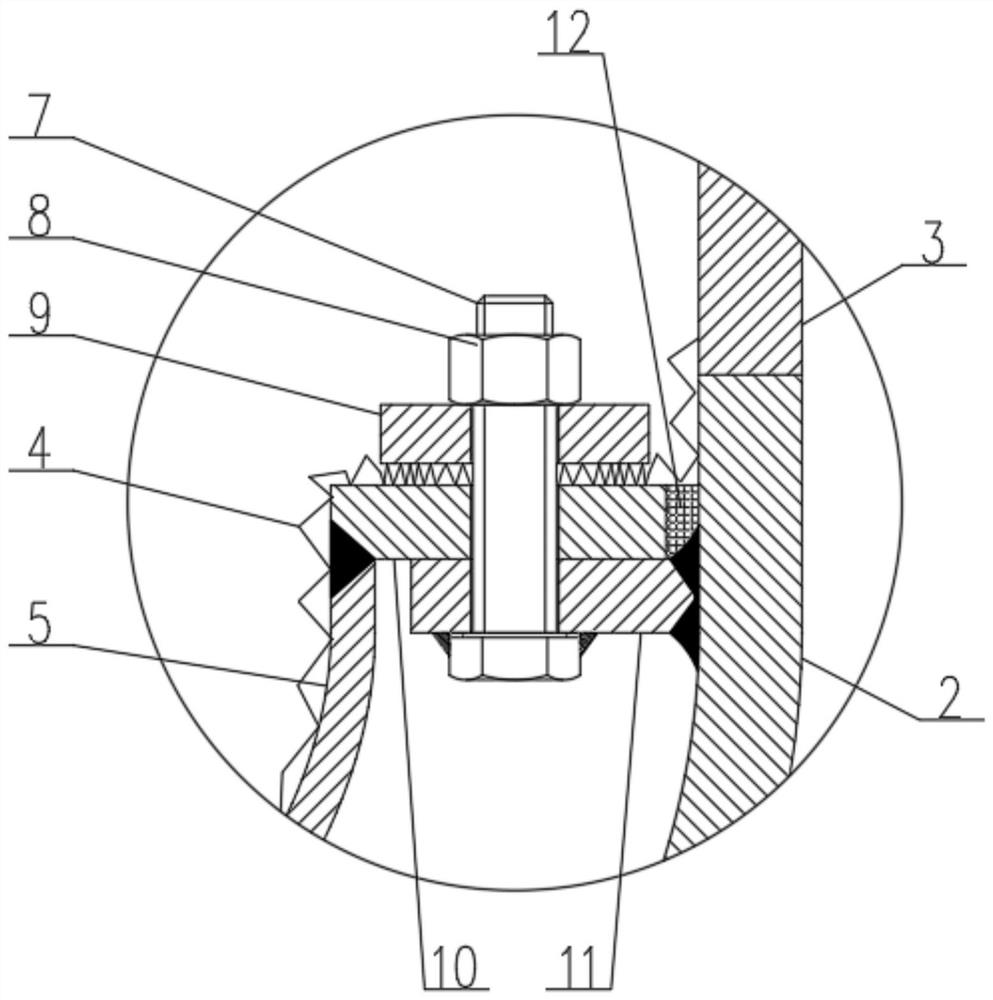

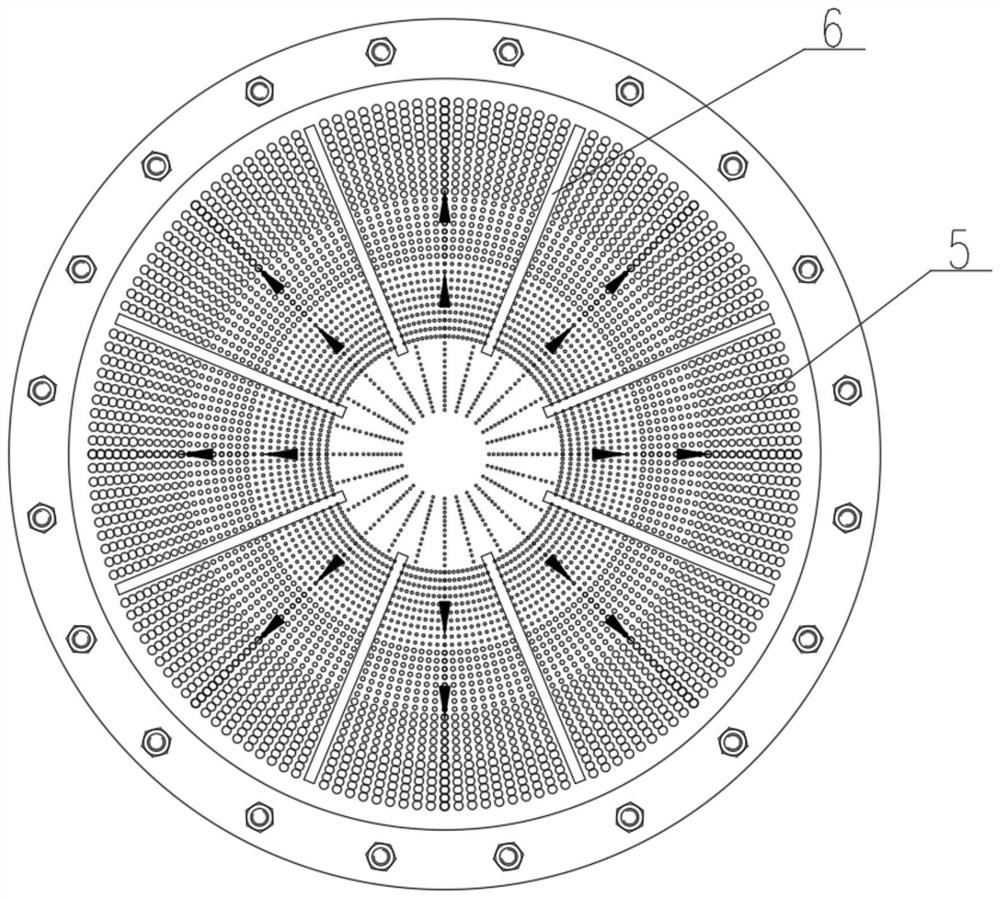

[0022] Such as Figure 1-4 As shown: the present invention includes an adsorption tower body 3, the lower end of the adsorption tower body 3 is provided with a convex adsorption tower head 2 and an air inlet forging pipe 1, and the air inlet forging pipe 1 is connected with the convex adsorption tower The middle part of the head 2 is communicated and connected, and a diversion support device is arranged in the head 2 of the convex adsorption tower close to the forged pipe 1 of the air inlet, and the diversion support device is connected with the seal of the convex adsorption tower. There is a gap between the inner walls of the head 2 .

[0023] Further, the diversion support device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com