Removing type anchorage device

An anchoring and removal technology, which is used in the installation of anchor rods, sheet pile walls, mining equipment, etc., can solve the problem of inability to remove tension members for disassembly, increased difficulty in processing and assembly, and cumbersome removal of tension members. problems, to achieve excellent technical difficulty, unique technical difficulty, and improve the effect of mechanical reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

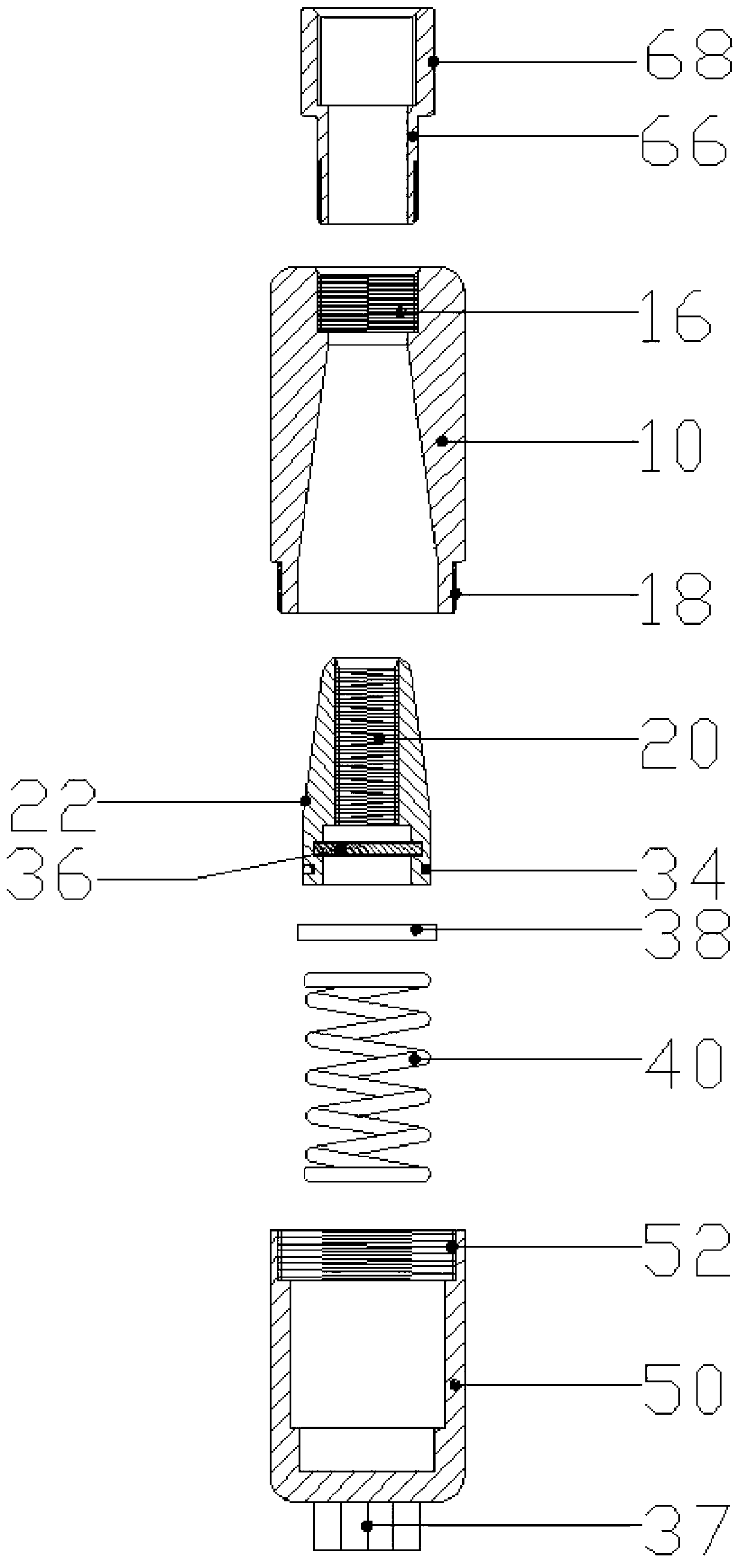

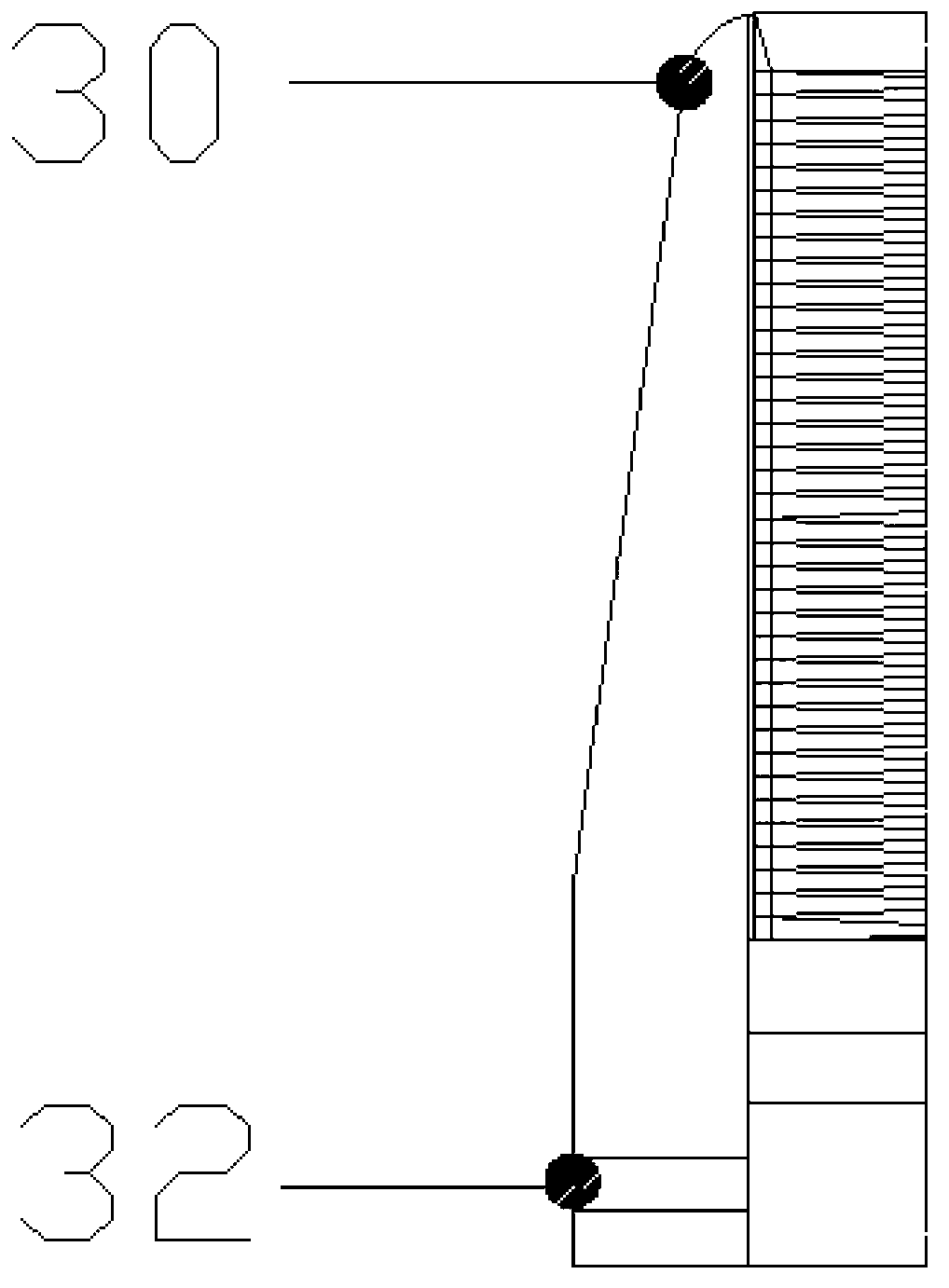

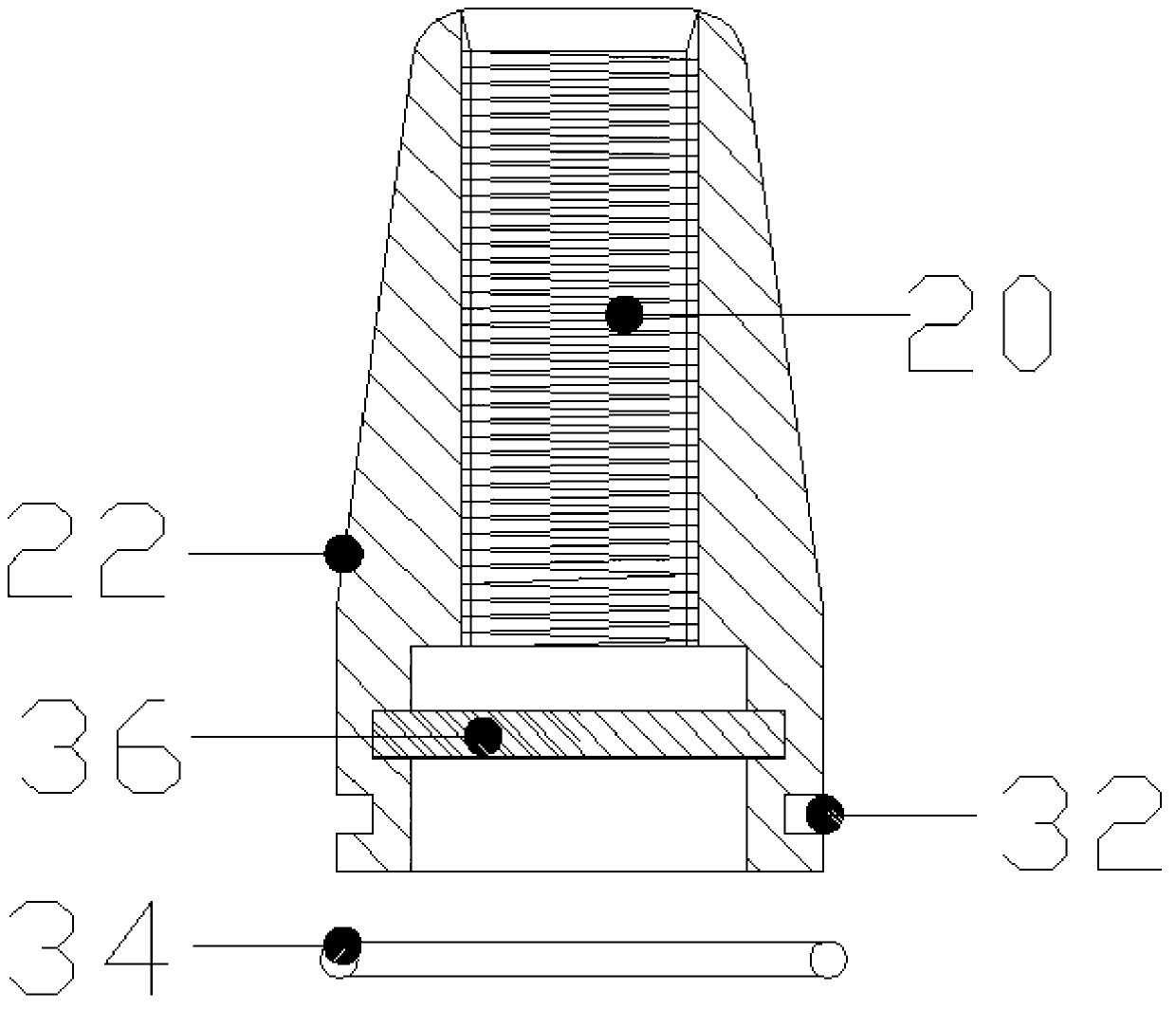

[0030] Removable anchors, such as Figure 1 to Figure 7 As shown, it includes a waterproof cover 10, an anchor ring extrusion sleeve 22, a spring 40 and a headgear 50, and also includes a leaf spring 38. The inside of the waterproof cover 10 is a tapered groove with a narrow top and a wide bottom. The anchor ring extrusion sleeve 22 is composed of three Made up of two clips 30 of the same shape, the shape of the anchor ring extrusion sleeve 22 is tapered with a narrow top and a wide bottom. Fixed ring 34, leaf spring 38 are placed between anchor ring extrusion sleeve 22 and spring 40, leaf spring 38 outer diameter is identical with anchor ring extrusion sleeve 22 lower end outer diameters, and headgear 50 is the closed cylinder body of top open bottom. The anchor ring extrusion sleeve 22 can move in the tapered groove, and the leaf spring 38 is used to support the anchor ring extrusion sleeve 22 and prevent the three clips 30 from moving up and down relative to each other.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com