Plasma device for waste treatment and treatment method thereof

A waste treatment and plasma technology, which is applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems that waste cannot be reused, the process flow is complex, and the structure is complex, and the structure is simple and the process flow is simple. The effect of simplification and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

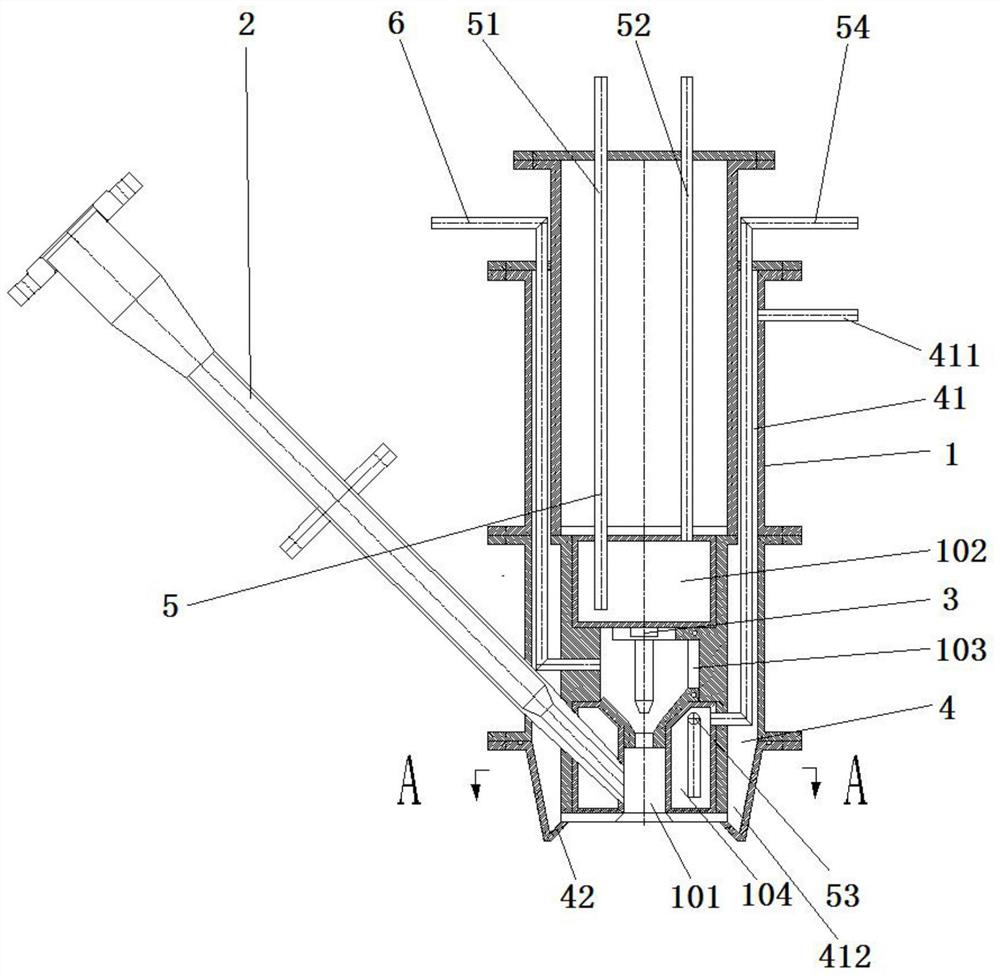

[0029] The plasma device for waste treatment, as shown in the figure, includes a furnace body 1, a waste powder treatment chamber 101 is provided in the furnace body 1, and solid waste powder communicated with the waste powder treatment chamber 101 is also installed on the furnace body 1 The body channel pipe 2 also includes a plasma generator 3, and the plasma generator 3 emits a high-temperature plasma arc to the waste powder processing chamber 101.

[0030] An oxygen supply device 4 is also included, and the oxygen supply device 4 delivers oxygen to the waste powder processing chamber 101 .

[0031] Through the combustion aid of plasma flame and oxygen, the solid waste powder is melted into a glass-like substance, which becomes a crystal through rapid cooling.

Embodiment 2

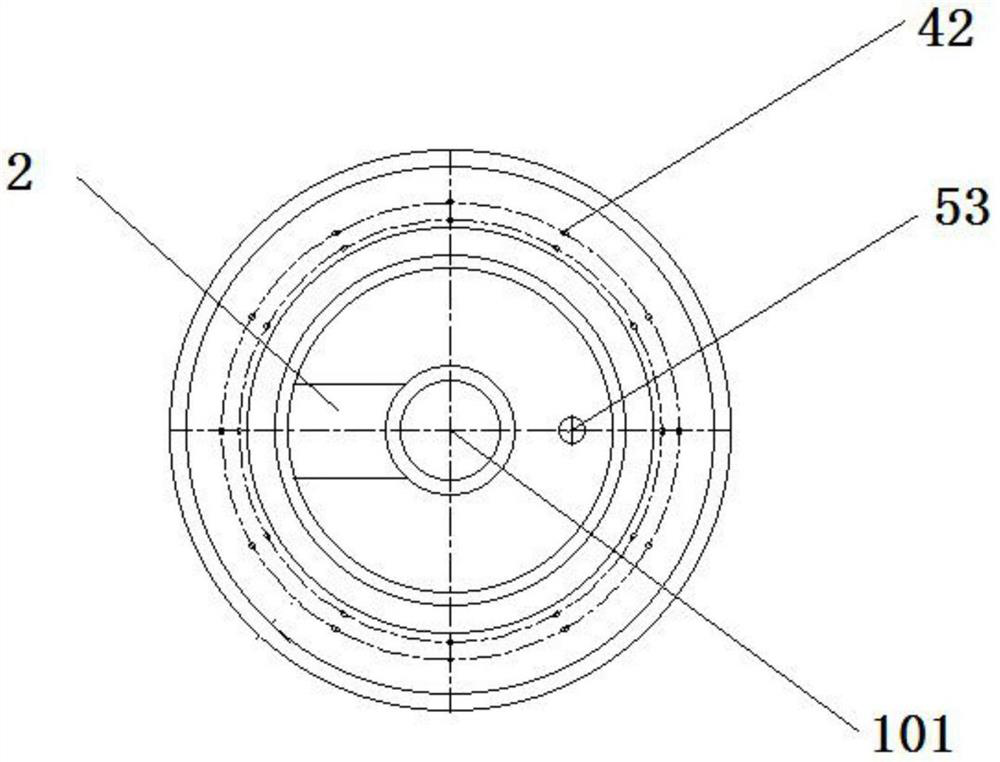

[0033] Same as Embodiment 1, the difference is that the oxygen supply device 4 includes an oxygen delivery pipe 41 and an oxygen supply device connected to the oxygen delivery pipe 41, the oxygen delivery pipe 41 is sleeved outside the furnace body 1 and forms an annular shape with the outer wall of the furnace body 1 The upper end of the oxygen delivery pipe 41 is provided with an oxygen inlet 411 , and the lower end of the oxygen delivery pipe 41 is provided with an oxygen outlet 412 communicating with the waste powder processing chamber 101 .

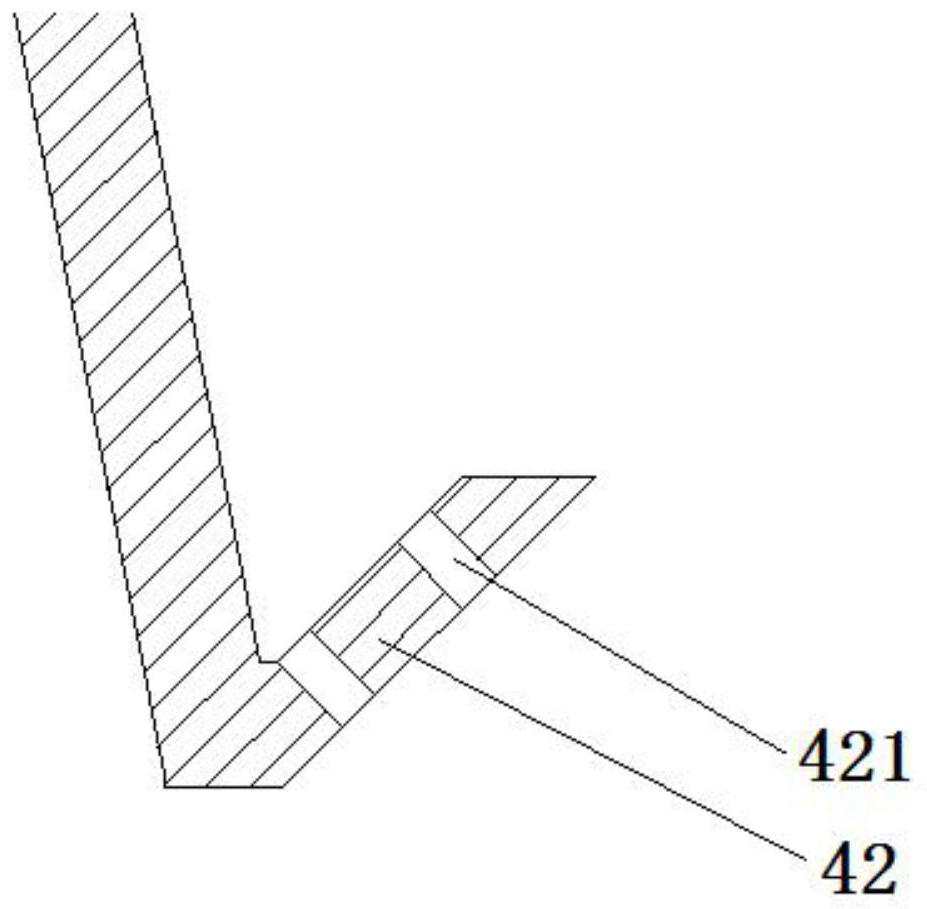

[0034] The oxygen outlet 412 end of the oxygen delivery pipe 41 is provided with an oxygen end face 42 extending toward the central axis of the oxygen delivery pipe 41. There is a small hole 421 and oxygen is injected through the small hole 421 . The oxygen jetted out through the small hole 421 mainly has combustion-supporting and protective effects. The organic matter in the solid waste powder is further burned, and the oxygen furth...

Embodiment 3

[0039] Same as embodiment 1, the difference is that it also includes a cooling device 5, the cooling device 5 includes an upper water inlet pipe 51, an upper water outlet pipe 52, a lower water inlet pipe 53, a lower water outlet pipe 54, an upper water inlet pipe 51, an upper water outlet pipe 52 and an upper cooling chamber The chamber 102 is connected, and the lower water inlet pipe 53 and the lower water outlet pipe 54 are connected with the lower cooling chamber 104; A water pump is installed on the water pipe 51 , and the lower water outlet pipe 54 is located in the oxygen delivery pipe 41 and stretches out of the furnace body 1 upwards. It mainly cools the two poles of the plasma generator. The cathode and anode of the plasma generator are water-cooled separately. The two water-cooling passages of cathode and anode respectively have water inlet pipe 51 and water outlet pipe 52, and the end of water inlet pipe is connected with water pump, utilizes low inlet and high ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com