Fire flooding assisted gravity drainage injection-production system and injection-production method based on intelligent temperature control

An intelligent temperature control, gravity-assisted technology, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve problems such as labor consumption, pipe string burnout, gas channeling, etc., to reduce the number of operations and reduce heat. effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

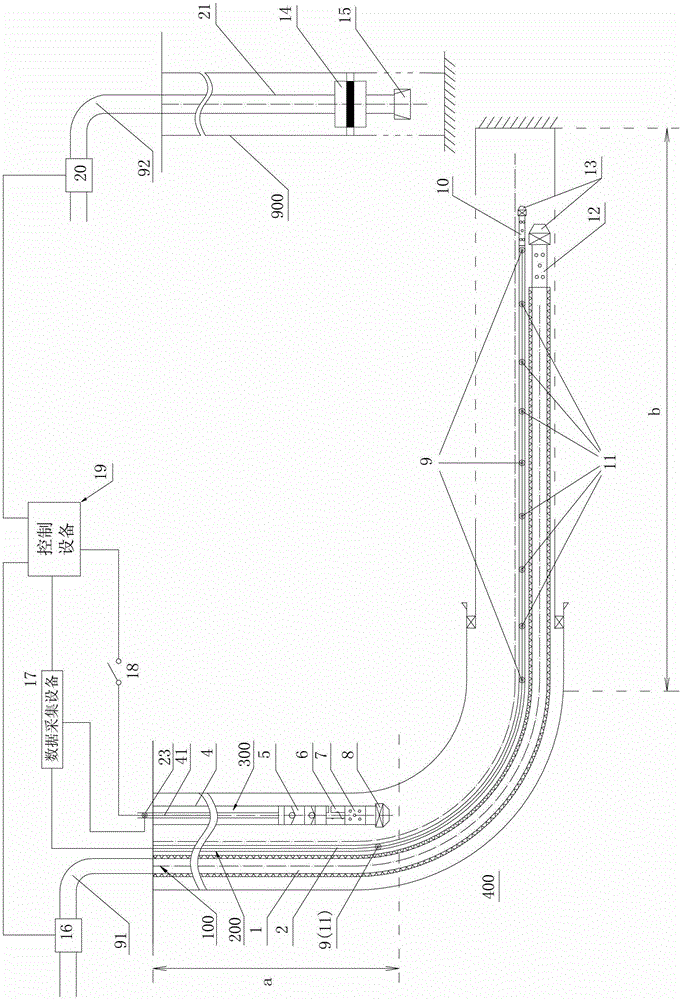

[0040] In order to have a more complete and clear disclosure of the invention purpose, technical means and technical effects of the present invention, a detailed description is given below, and please also refer to the accompanying drawings and component numbers.

[0041] Such as figure 1 As shown, a fire-flooding assisted gravity drainage injection-production system based on intelligent temperature control is provided with three independent strings of injection string 100, monitoring string 200 and production string 300 in the production well 400. The gas injection well 900 is equipped with a gas injection string and an intelligent temperature control device for intelligently regulating the temperature of the production liquid, among which:

[0042] The injection string 100 includes a thermal insulation pipe 1, a screen pipe 12, and a guide cone 13 connected in series, and the monitoring pipe string 200 includes a monitoring pipe 2, a screen pipe 10, and a guide cone 13 conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com