Positive extrusion test method for plastic forming friction coefficient and friction factor

A friction coefficient and friction factor technology, which is applied in the field of plastic forming friction coefficient and friction factor testing, can solve the problems of difficulty in accurately determining the position of the neutral plane, accurate measurement data, few practical applications, and inconvenient operation. Easy to operate and easy to process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation of the present invention will be described below by taking the determination of the friction coefficient and friction factor of the thermoplastic forming process of AZ31 magnesium alloy at 200°C and the plastic forming process of 1100 aluminum alloy at room temperature as an example.

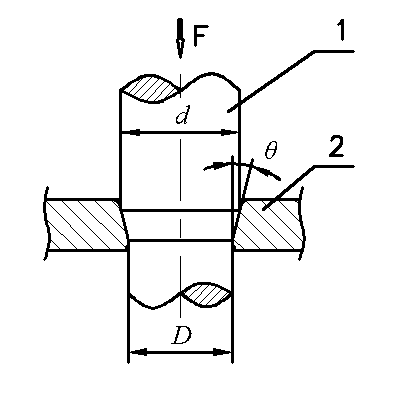

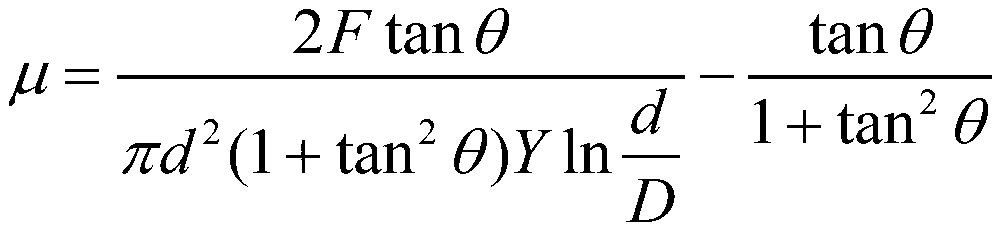

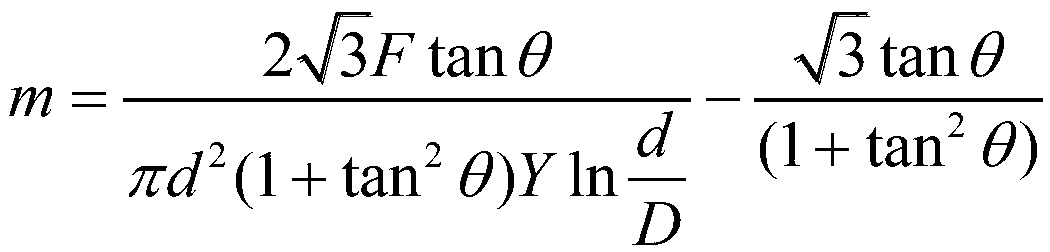

[0031] In the embodiment, the mold material of the conical die is T10A, the diameter d of the 1100 and AZ31 cylindrical blank is 18mm, the height H is 40mm, the taper angle θ of the conical die is 30°, and the diameter D of the small port is 16mm .

[0032] (1) Determination of friction coefficient μ and friction factor m during hot forming of AZ31 magnesium alloy at 200°C

[0033] 1) Using the high-temperature tensile test standard for metal materials (GB / T4338-1995), use the AZ31 material to be tested to make a tensile test sample, and measure the yield stress Y of the material at a temperature of 200°C. In this example, the measured value of Y is 105MPa;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com