Liquid crystal panel and display device thereof

A liquid crystal panel and liquid crystal layer technology, applied in the direction of nonlinear optics, instruments, optics, etc., can solve the problems of long production time of liquid crystal panel and high complexity of liquid crystal panel process, and achieve improved ESD resistance, simple manufacturing process, damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

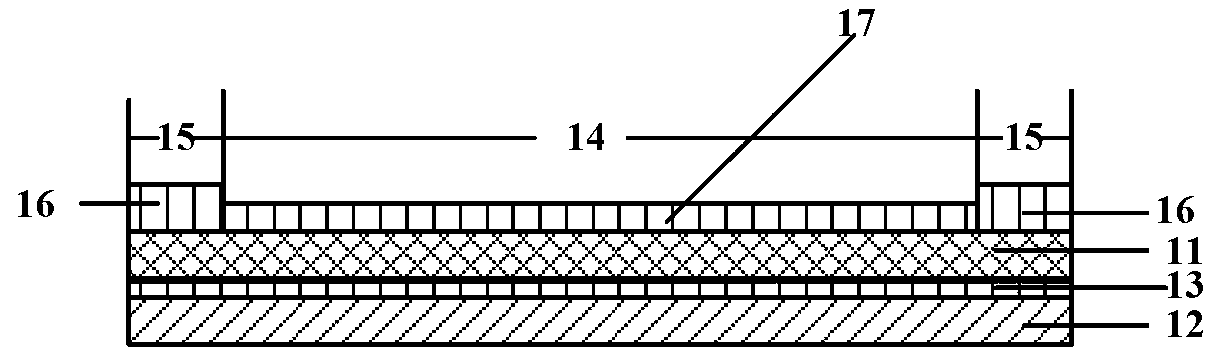

[0024] Such as figure 2 As shown, it is a schematic structure of a liquid crystal panel in the first embodiment. The liquid crystal panel includes: a first substrate 11 and a second substrate 12 oppositely arranged, and a liquid crystal layer 13 filled between the first substrate and the second substrate, the liquid crystal panel includes a display area 14 and a non-display area 15, The non-display area 15 is disposed around the display area 14, and a first shielding layer 16 is disposed on the non-display area 15 on the side away from the liquid crystal layer on the first substrate.

[0025] Preferably, the first substrate 11 is a color filter substrate, and the second substrate 12 is an array substrate.

[0026] Specifically, the first shielding layer 16 of the non-display area 15 may cover the entire non-display area of the liquid crystal panel, or cover a part of the non-display area of the liquid crystal panel according to actual needs, wherein the first shielding l...

Embodiment 2

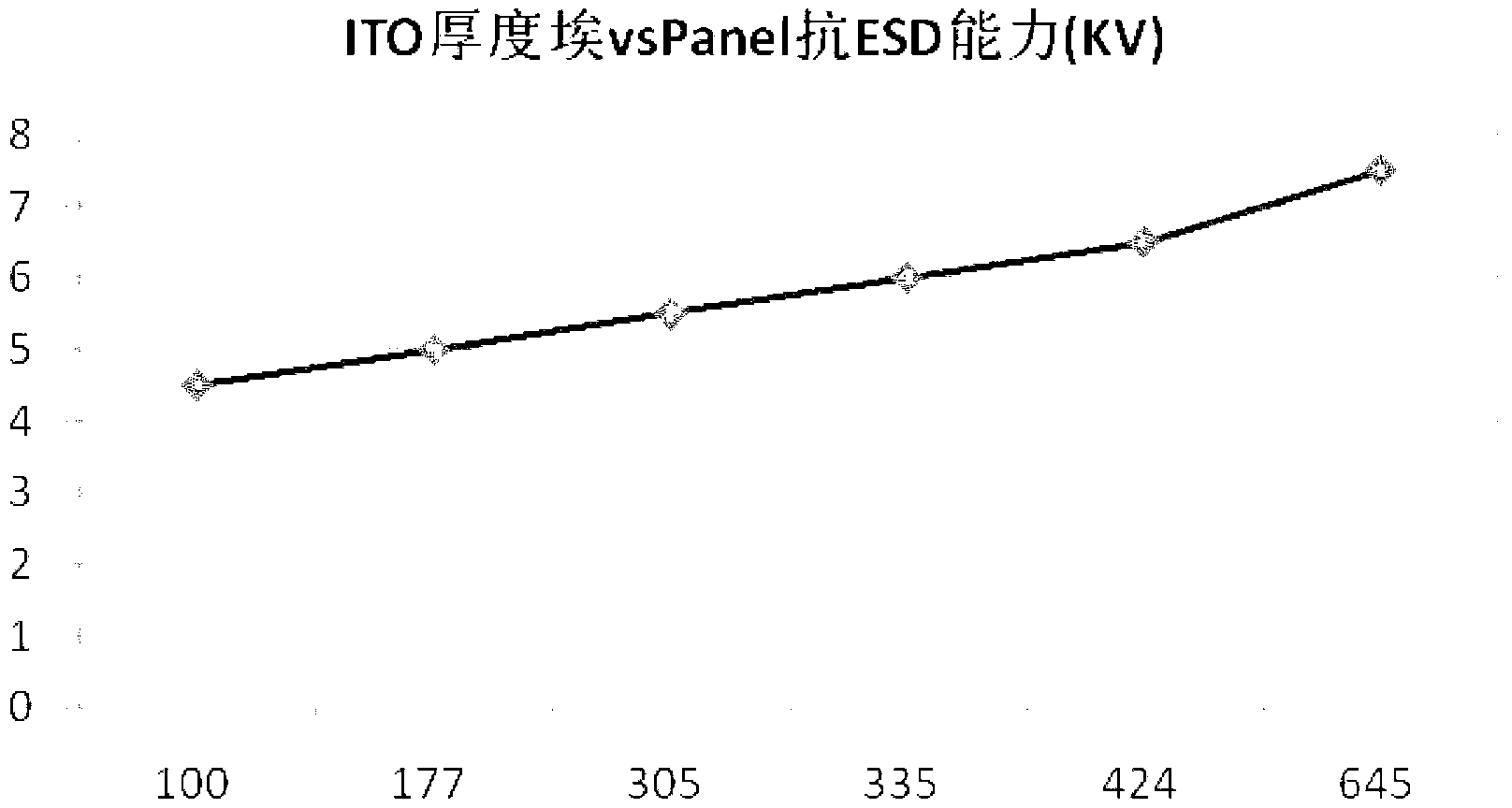

[0041]Assuming that the LCD panel adopts the IPS (In-Plane Switching, in-plane switching) mode, the first substrate is a color filter substrate, and the second substrate is an array substrate. Using the solution of Embodiment 1, set the first panel in the non-display area of the color filter substrate. For the shielding layer, a second shielding layer is provided on the display area of the color filter substrate, wherein the material of the first shielding layer and the second shielding layer is ITO.

[0042] Specifically, the thickness of the second shielding layer set in the display area is controlled at about 100 angstroms, while the thickness of the first shielding layer set in the non-display area can reach 600 angstroms, which not only ensures the display requirements of the display area, that is, the display area The second shielding layer can play the role of shielding the external electric field, so as to prevent the external electric field from interfering with th...

Embodiment 3

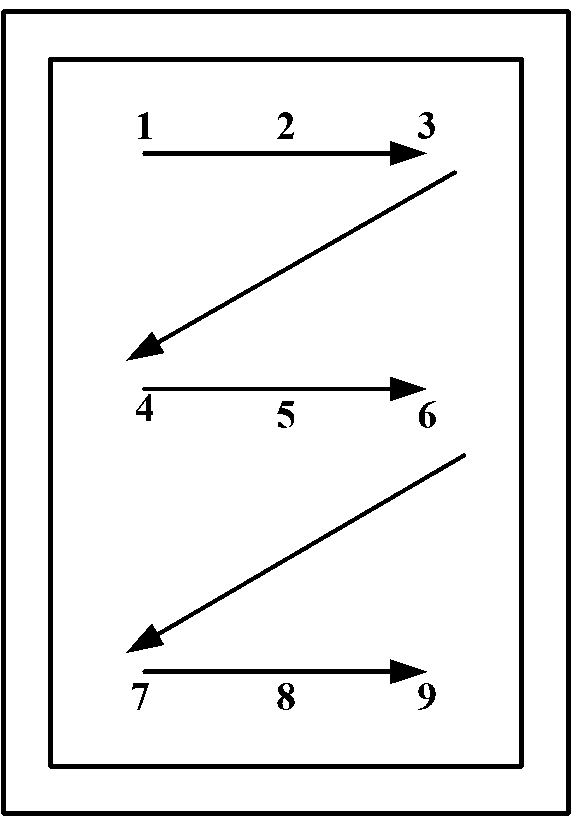

[0046] Such as Figure 7 As shown, it is a flowchart of a method for manufacturing a liquid crystal panel in Embodiment 3, and the method includes:

[0047] Step 101: providing a first glass substrate.

[0048] Step 102: Forming a first ITO layer on the first glass substrate by means of PVD coating.

[0049] Wherein, the first ITO layer in the display area of the first glass substrate is the second shielding layer provided in the first embodiment.

[0050] Specifically, the thickness of the first ITO layer is 100 angstroms.

[0051] Step 103: After covering all the display areas on the first glass substrate with a mask, a second ITO layer is formed on the entire first glass substrate by PVD coating.

[0052] Wherein, the thickness of the second ITO layer is 500 angstroms.

[0053] It should be noted that the first ITO layer and the second ITO layer in the non-display area of the first glass substrate are combined to form the first shielding layer provided in the first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com