Detecting mistake-proof system applicable to electronic part production line and method thereof

A technology of electronic components and error-proofing systems, applied in general control systems, control/regulation systems, program control, etc., to achieve the effect of reducing manual labor, improving quality, and reducing loss of normal production hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

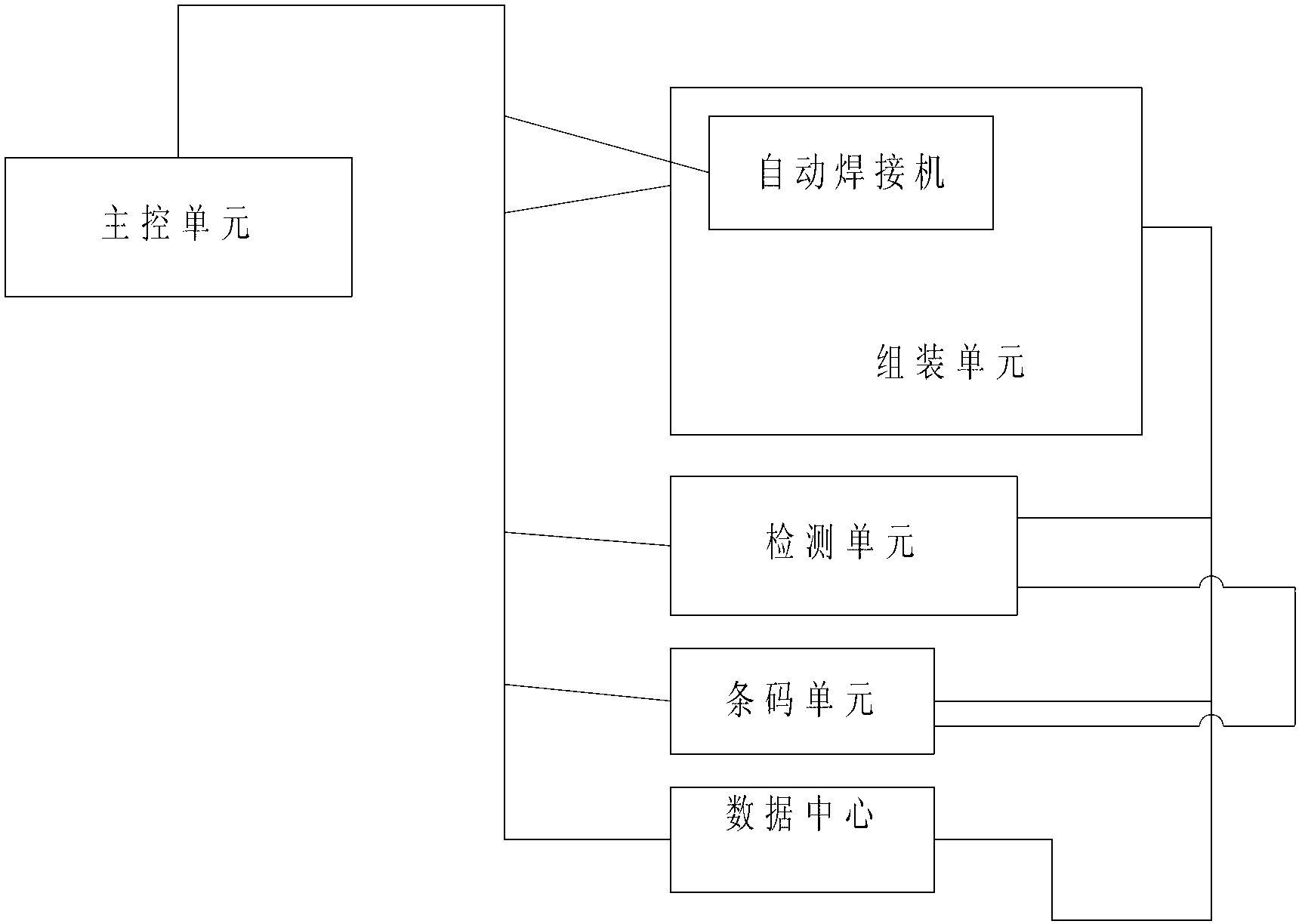

[0037] like figure 1 Shown is a detection and error prevention system suitable for electronic component production lines according to an embodiment of the present invention, including a main control unit, a data center, a barcode unit, an assembly unit, and a detection unit. At the same time, the assembly unit includes an automatic welding machine, and the automatic The welding machine is a programmable welding machine, which replaces manual labor to improve efficiency and quality.

[0038] Wherein, the main control unit is respectively connected with the data center, the barcode unit, the assembly unit detection unit and the automatic welding machine; the data center is respectively connected with the barcode unit, the assembly unit and the detection unit; the barcode u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com