A Method of Debugging Control Software of Frequency Converter During High Power Test

A technology of inverter control and control software, applied in the field of testing, can solve the problems of inverter damage, inconvenient debugging, circuit failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A method for debugging the inverter control software during high-power tests: When designing the inverter control software, the control software header file containing the key parameters of the inverter is used as the configuration file, the relative positions between the variables are fixed, and the variable addresses are used as The only key field is used for identification; when performing a high-power test, the host computer imports the control software header file, so that the host computer obtains the right to control the key variables and state quantities of the inverter control software. The key parameters of the frequency converter include bus voltage sampling actual value, A phase current actual value, B phase current actual value, C phase current actual value, bus voltage sampling filter value, A phase current filter value, B phase current filter value, C phase Current filter value, d-axis current loop proportional coefficient, d-axis current loop integral coe...

Embodiment 2

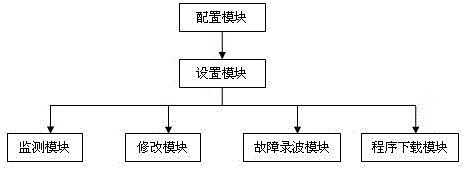

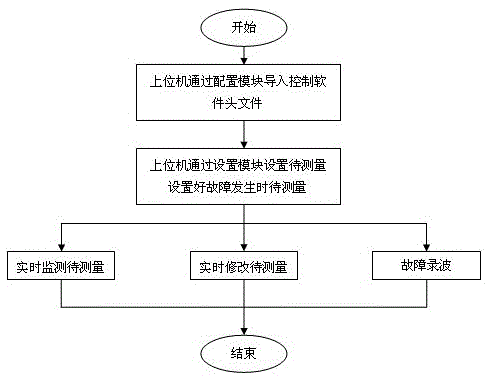

[0020] Different from above-mentioned embodiment 1, say further, if figure 1 As shown, the debugging interface of the upper computer is programmed by using the object-oriented programming language. This debugging interface has at least a configuration module, a setting module, a monitoring module, a modification module, a fault recording module, and a program download module. During the high-power test, the process of debugging the control software of the frequency converter refers to figure 2 shown. The upper computer imports the control software header file through the configuration module, so that the upper computer obtains the right to control the key variables and state quantities of the inverter control software. The upper computer first sets the key variables and state quantities required for the test online through the setting module, sets the key variables and state quantities when a fault occurs, monitors the variable changes in real time through the monitoring mod...

Embodiment 3

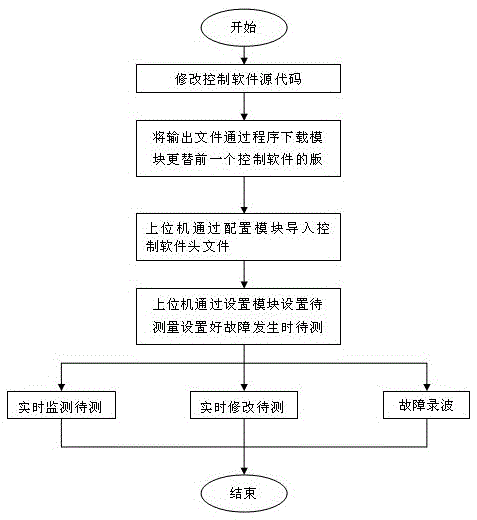

[0022] The difference from the above-mentioned embodiment 2 is that further, when performing high-power tests, the process of debugging the new version of the inverter control software refers to image 3 shown. After modifying the source code of the inverter control software, the output file will be replaced by the previous version of the inverter control software through the program download module. The upper computer only needs to re-import the control software header file to be compatible with the modified control software, so as to be compatible with different inverter control software versions. The upper computer first sets the key variables and state quantities required for the test online through the setting module, monitors the variable changes in real time through the monitoring module, and changes the key variables and state quantities in real time by modifying the module when the inverter status needs to be changed. Good fault recording module, when a fault occurs,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com