Composition for optical material

A technology of optical materials and compositions, applied in optics, optical components, instruments, etc., can solve problems such as uneven polymerization, and achieve the effect of suppressing uneven polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

[0058]Preferable examples of the ultraviolet absorber include benzotriazole compounds. Specific examples of particularly preferred compounds include: 2-(2-hydroxy-5-methylphenyl)-2H-benzotriazole, 5-chloro-2-(3,5-di-tert-butyl-2-hydroxy Phenyl)-2H-benzotriazole, 2-(3-tert-butyl-2-hydroxy-5-methylphenyl)-5-chloro-2H-benzotriazole, 2-(3,5- Di-tert-amyl-2-hydroxyphenyl)-2H-benzotriazole, 2-(3,5-di-tert-butyl-2-hydroxyphenyl)-2H-benzotriazole, 2-(2- Hydroxy-4-octyloxyphenyl)-2H-benzotriazole and 2-(2-hydroxy-5-tert-octylphenyl)-2H-benzotriazole. Preferable examples of the bluing agent include anthraquinone compounds.

[0059] In addition, when the composition for optical materials of the present invention is difficult to take out from the mold, known external and / or internal mold release agents may be used or added to improve the mold release properties of the resulting cured material. Examples of the release agent include: nonionic fluorine-based surfactants, nonionic silicon-...

Embodiment 1

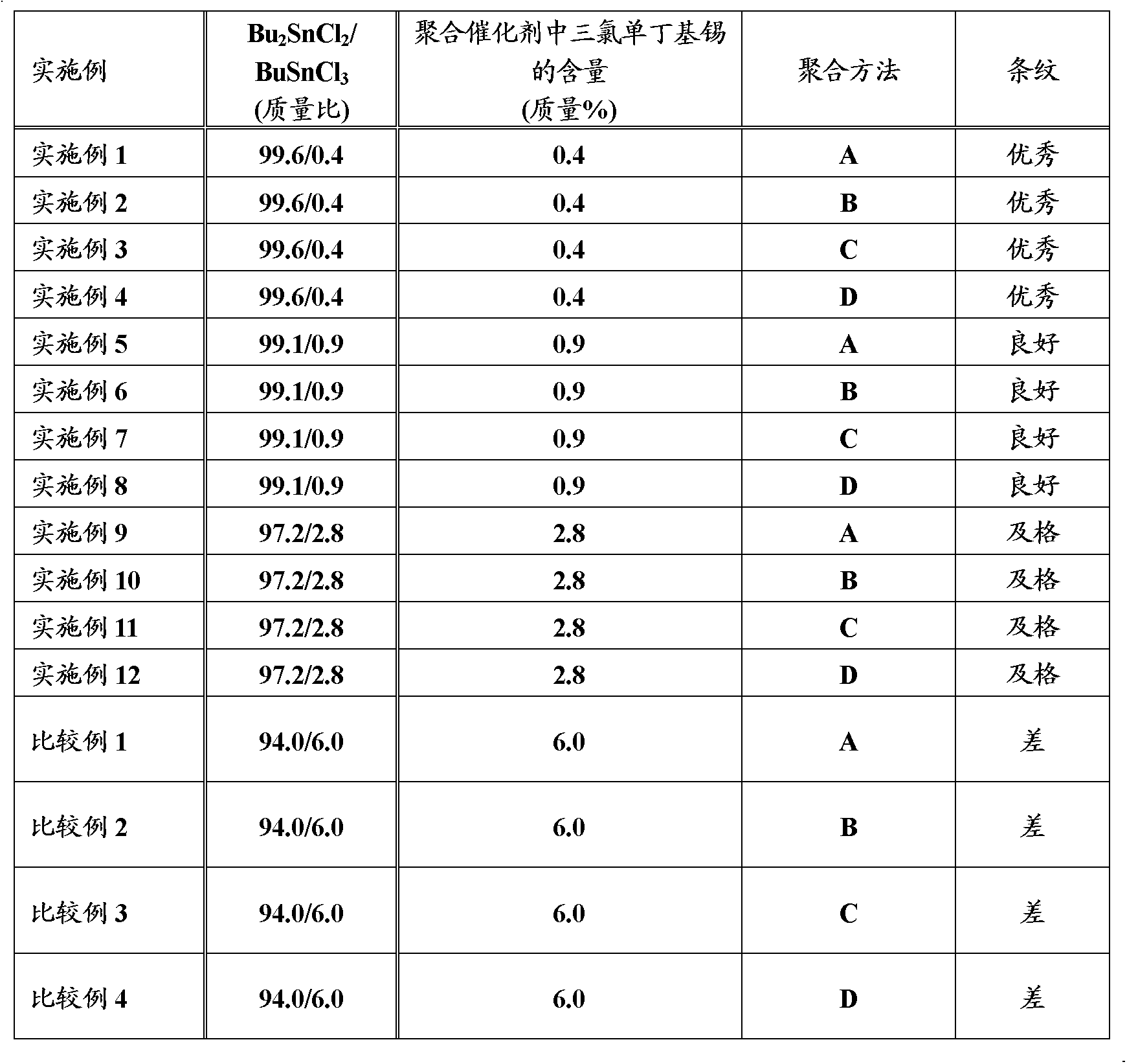

[0082] The curing was performed by polymerization method A using a polymerization catalyst comprising 99.6% by mass of dibutyltin dichloride and 0.4% by mass of monobutyltin trichloride. The observed results were rated as excellent streak suppression. The evaluated results are shown in Table 1.

Embodiment 2 to 4

[0084] Curing was performed by the polymerization method shown in Table 1 using a polymerization catalyst containing 99.6% by mass of dibutyltin dichloride and 0.4% by mass of monobutyltin trichloride. The evaluated results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com