Combined type floating mat automatic bait-casting cultivation device

An automatic bait feeding and combined technology, applied in fish farming, application, animal husbandry, etc., can solve the problems of waste of labor and feed, poor wind resistance, high work intensity, etc., and achieve labor saving and large cage area , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

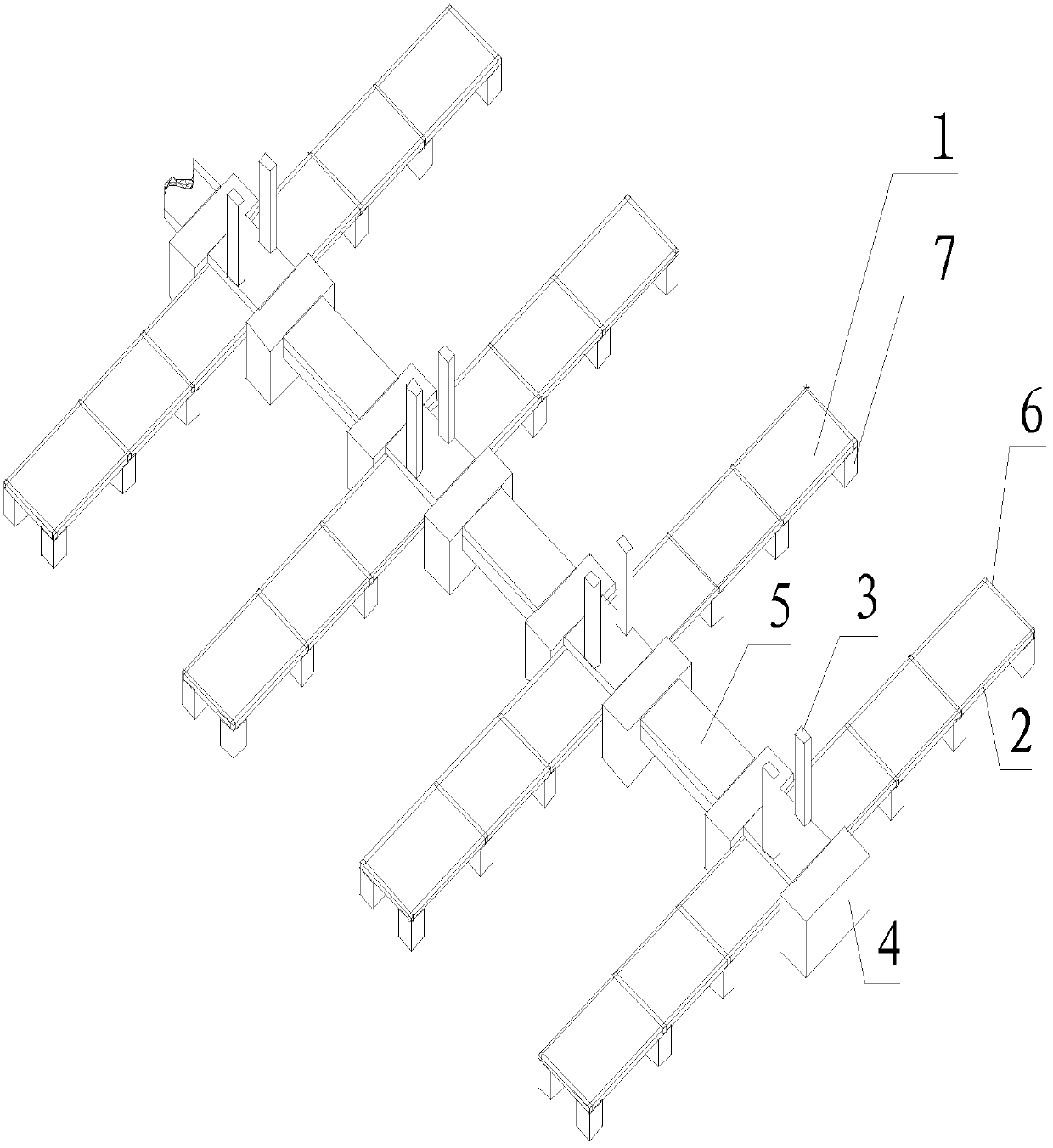

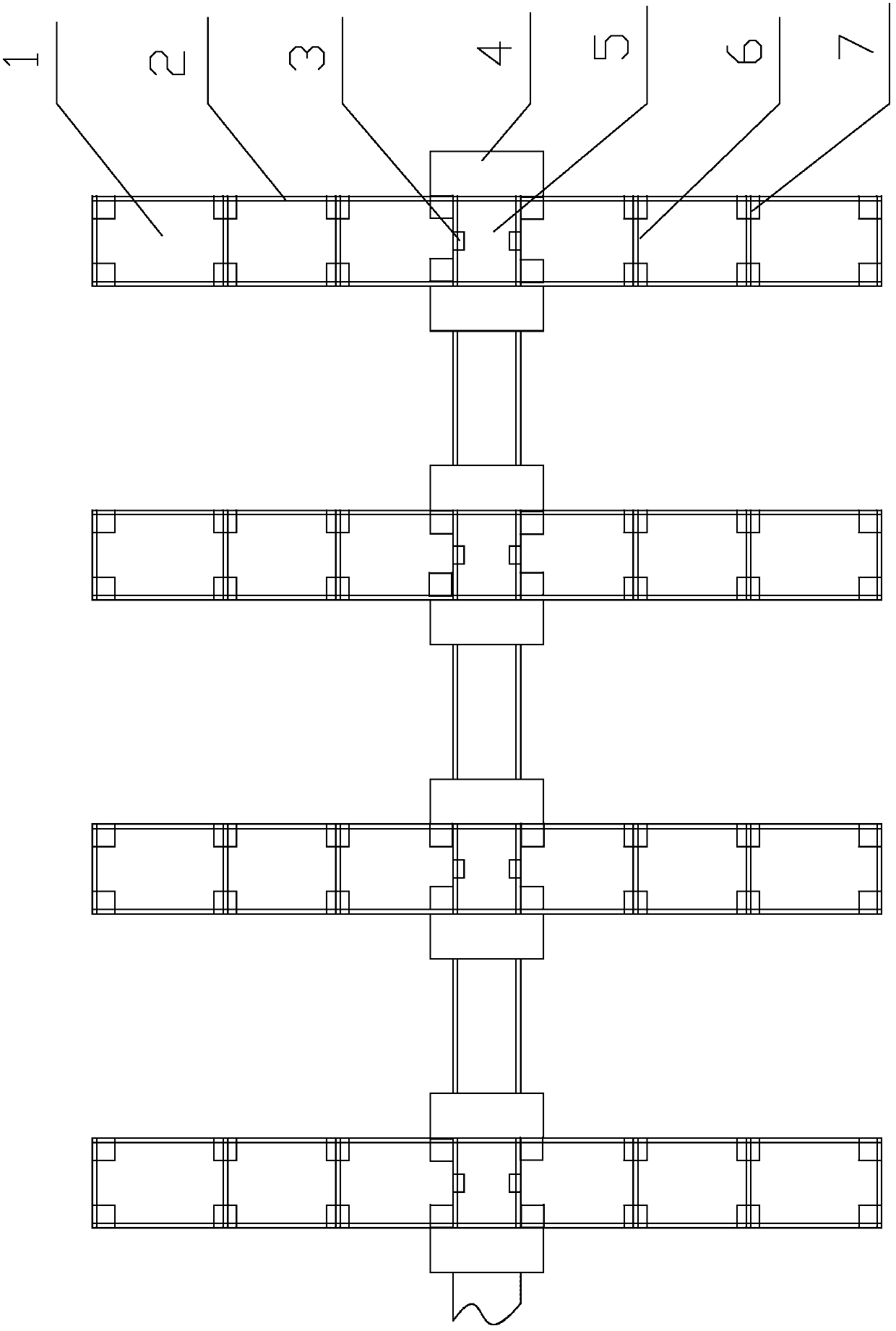

[0018] Such as figure 1 , figure 2 As shown, the present invention includes a pontoon, a net cage and an automatic bait thrower 3, wherein a plurality of net cages are symmetrically arranged on both sides of the pontoon, and each net cage corresponds to an automatic bait thrower 3 arranged on the pontoon . The pontoon bridge includes cantilever beams, buoys 4 and springboards 5, wherein there are multiple buoys 4 connected in series in sequence. Two adjacent buoys 4 are connected by the cantilever beam, and the cantilever beam is formed by welding a plurality of brackets between two angle irons parallel to each other, and each bracket is welded vertically to the angle iron. A plurality of springboards 5 are successively laid on each cantilever beam. The buoy 4 is welded by a plurality of iron plates, the outer surfaces of both ends of the buoy 4 are weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com