Preparation method and application of syrup

A syrup, glucose syrup technology, applied in application, food preparation, food science and other directions, can solve the problems of high sweetness, rapid loss of aroma, etc., and achieve the effect of reducing sweetness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

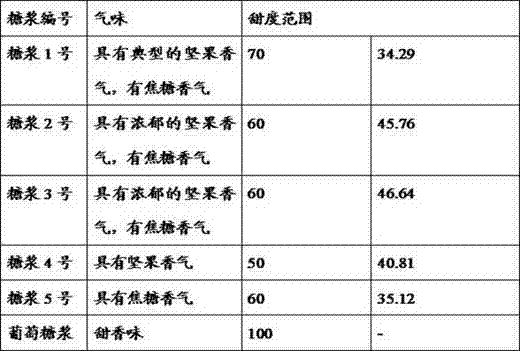

Examples

Embodiment 1

[0016] (1) Use defatted sunflower seeds as raw materials, crush them, mix with 3 times the weight of water, add flavor protease (Flavorzyme) for hydrolysis, when the degree of hydrolysis reaches 10%, inactivate the enzyme at 85°C for 30 minutes to stop the reaction, and obtain the enzymatic solution ;

[0017] (2) Filtrate the enzymatic solution to remove insoluble precipitates, pass through an ultrafiltration membrane with a molecular weight cut-off of 10kDa, take the permeate, concentrate it to a solid content of 65%, and obtain a protein hydrolyzate;

[0018] (3) Mix 100g of glucose syrup and 2g of protein hydrolyzate evenly, and react at 120°C for 1 hour to obtain Syrup No. 1.

Embodiment 2

[0020] (1) Use defatted sunflower seeds as raw materials, crush them, mix them with 4 times the weight of water, add papain for hydrolysis, and when the degree of hydrolysis reaches 13%, inactivate the enzyme at 95°C for 30 minutes to stop the reaction and obtain an enzymatic solution;

[0021] (2) Filtrate the enzymatic solution to remove insoluble precipitates, pass through an ultrafiltration membrane with a molecular weight cut-off of 10kDa, take the permeate, concentrate it to a solid content of 75%, and obtain a protein hydrolyzate;

[0022] (3) Mix 100g of glucose syrup and 1g of protein hydrolyzate evenly, and react at 100°C for 4 hours to obtain Syrup No. 2.

Embodiment 3

[0024] (1) Use defatted sunflower seeds as raw materials, crush them, mix them with 6 times the weight of water, add alkaline protease (Alcalase) for hydrolysis, and when the degree of hydrolysis reaches 15%, inactivate the enzyme at 90°C for 25 minutes to terminate the reaction and obtain enzymolysis liquid;

[0025] (2) Filtrate the enzymatic solution to remove insoluble precipitates, pass through an ultrafiltration membrane with a molecular weight cut-off of 10kDa, take the permeate, concentrate it to a solid content of 70%, and obtain a protein hydrolyzate;

[0026] (3) Mix 100g of glucose syrup and 3g of protein hydrolyzate evenly, and react at 110°C for 4 hours to obtain No. 3 syrup.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mwco | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com