Brake shoe bending plate continuous die and method for using continuous die to machine brake shoe bending plate

A technology for brake shoes and processing plates, which is used in manufacturing tools, metal processing equipment, forming tools, etc., can solve the problems of increasing the input of manpower and material resources, reducing the product qualification rate, and increasing the cost of investment, so as to improve work efficiency, Improve the production accuracy and ensure the effect of quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

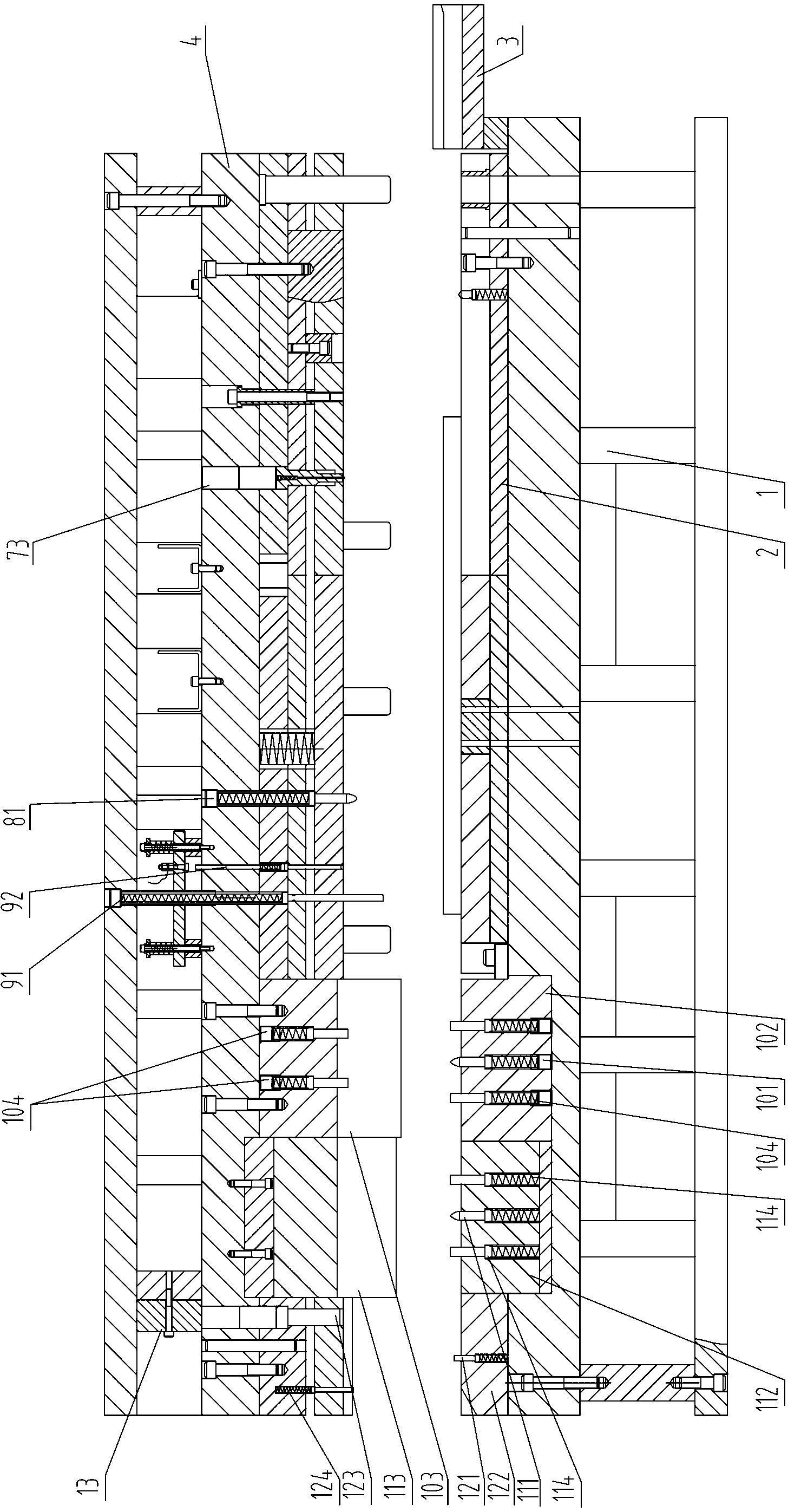

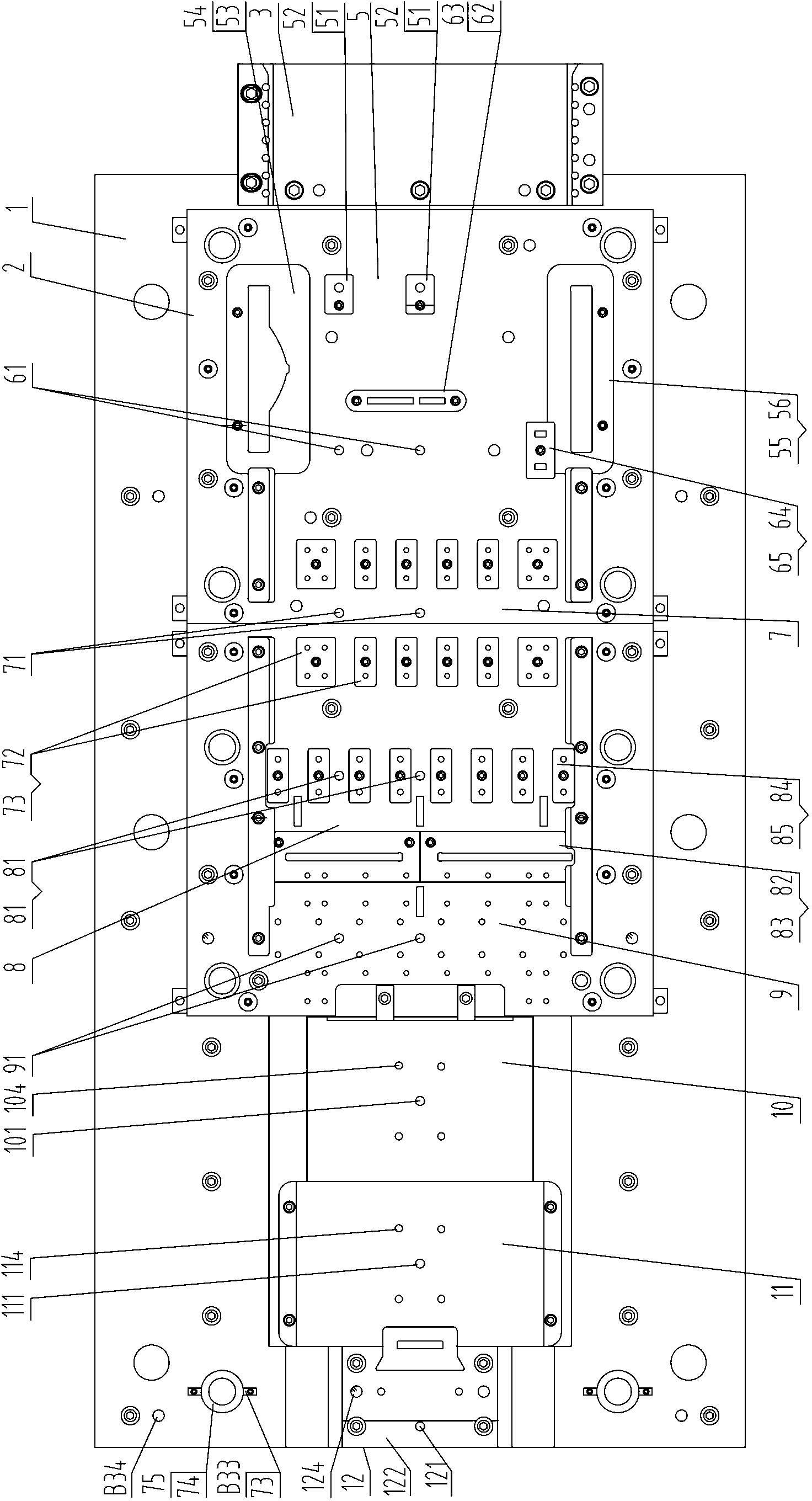

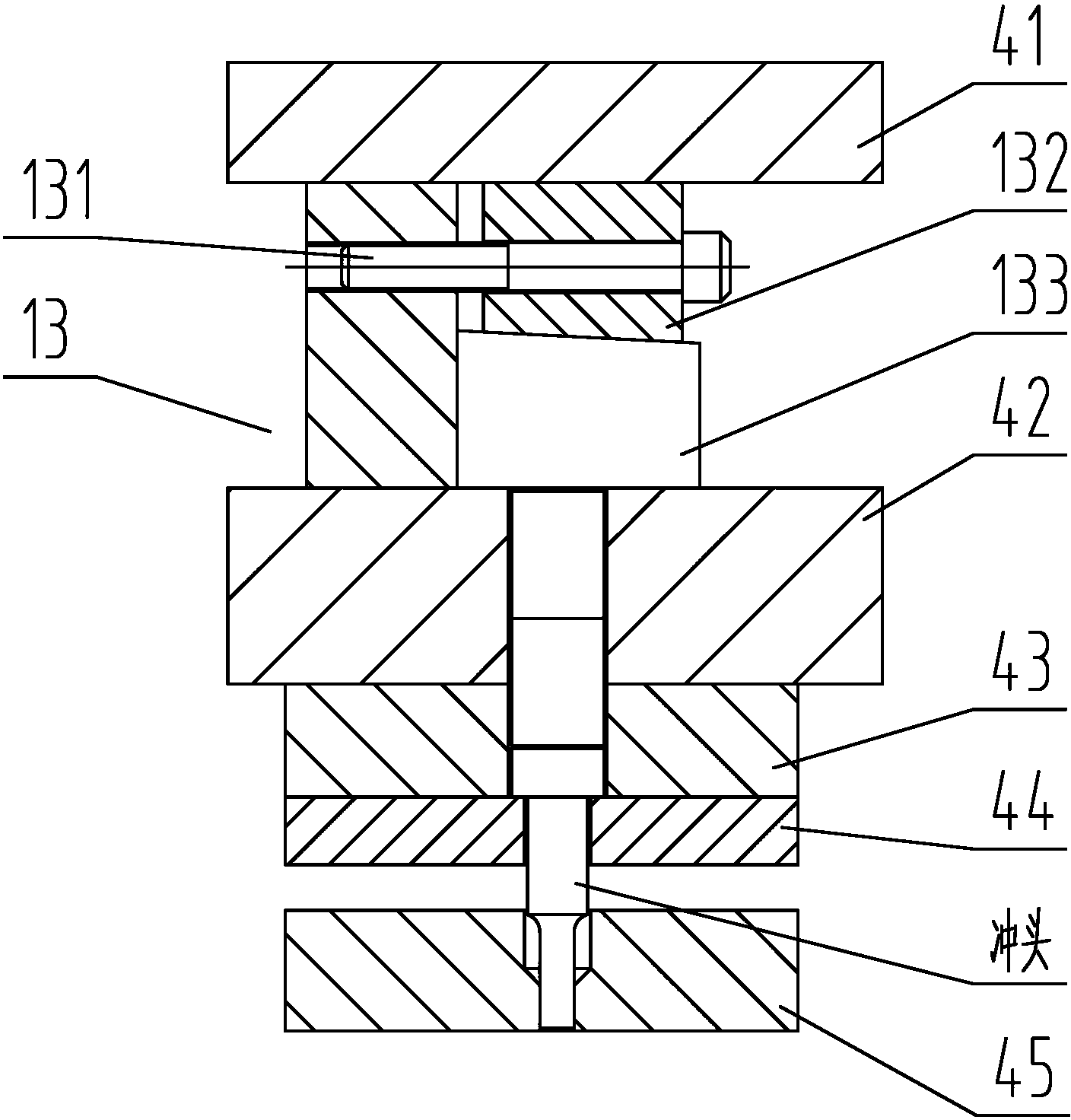

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

[0033] according to Figure 1 to Figure 4As shown, a brake shoe bending plate continuous mold according to the present invention includes a frame 1 and a workbench 2 installed on the frame 1. The workbench 2 is provided with a driving part, a blanking part 3, a processing The conveying part and the pressing part 4 that can move up and down, the driving part drives the processing conveying part and the pressing part 4 to run, so that the processed plate 14 enters the next processing procedure along the processing conveying part through the blanking part 3. Wherein, the workbench 2 is provided with a guiding processing part 5 for punching a positioning guide hole 141 and a trimming edge 142, a marking processing part 6 for marking a logo 143 and punching an elongated hole 144, and a marking processing part 6 for punching a rivet hole 145. The first punching part 7, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com