Automatic screen lettering and cutting machine and process

A yarn cutting machine and automatic technology, applied in metal processing, etc., can solve problems such as low production efficiency, large manpower consumption, and low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

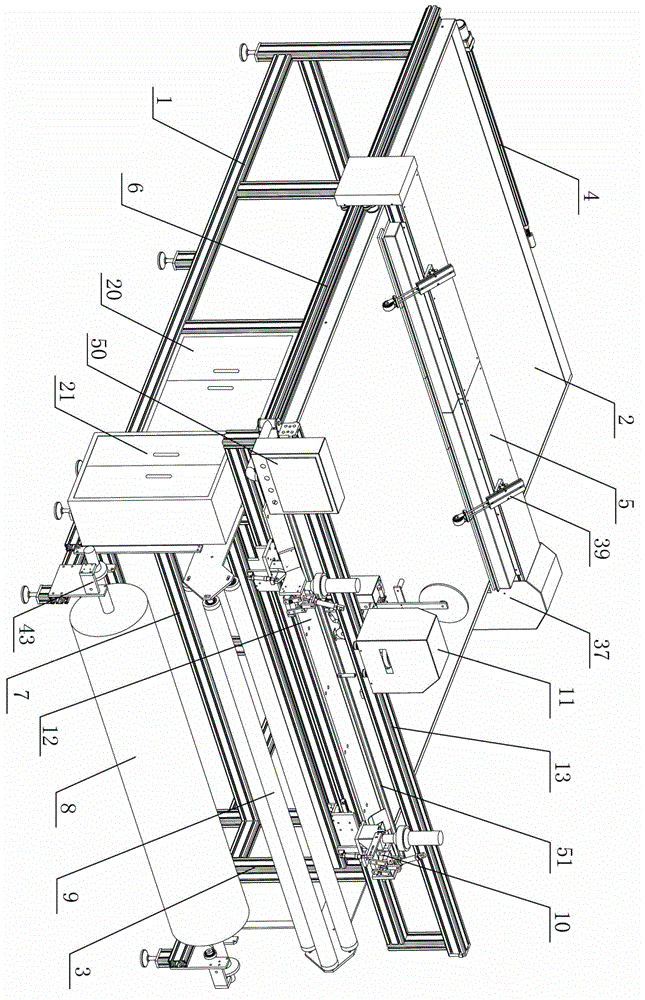

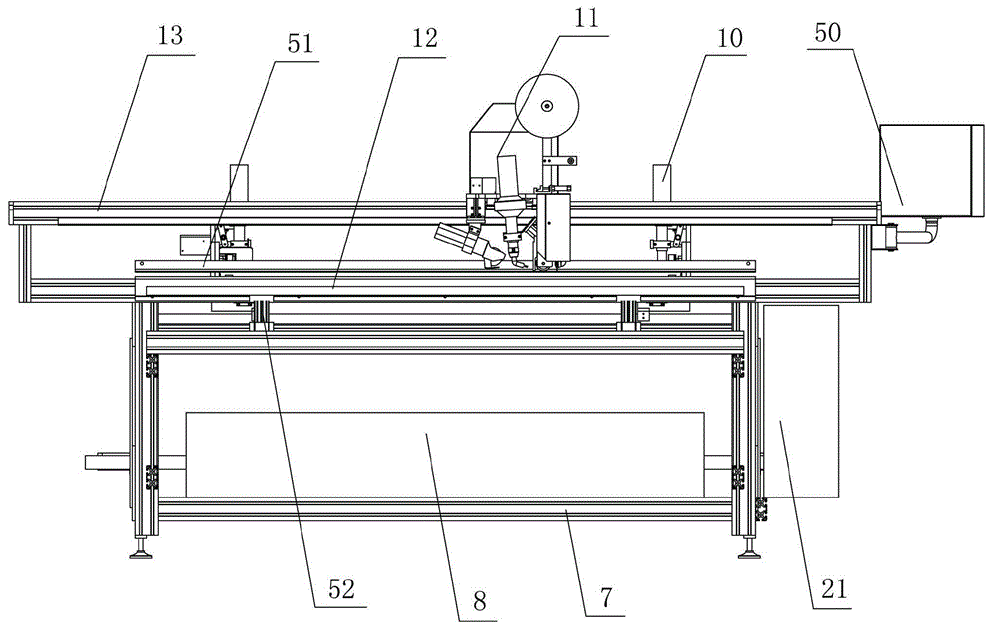

[0033] Such as Figure 1-10 As shown, an automatic ironing and cutting machine:

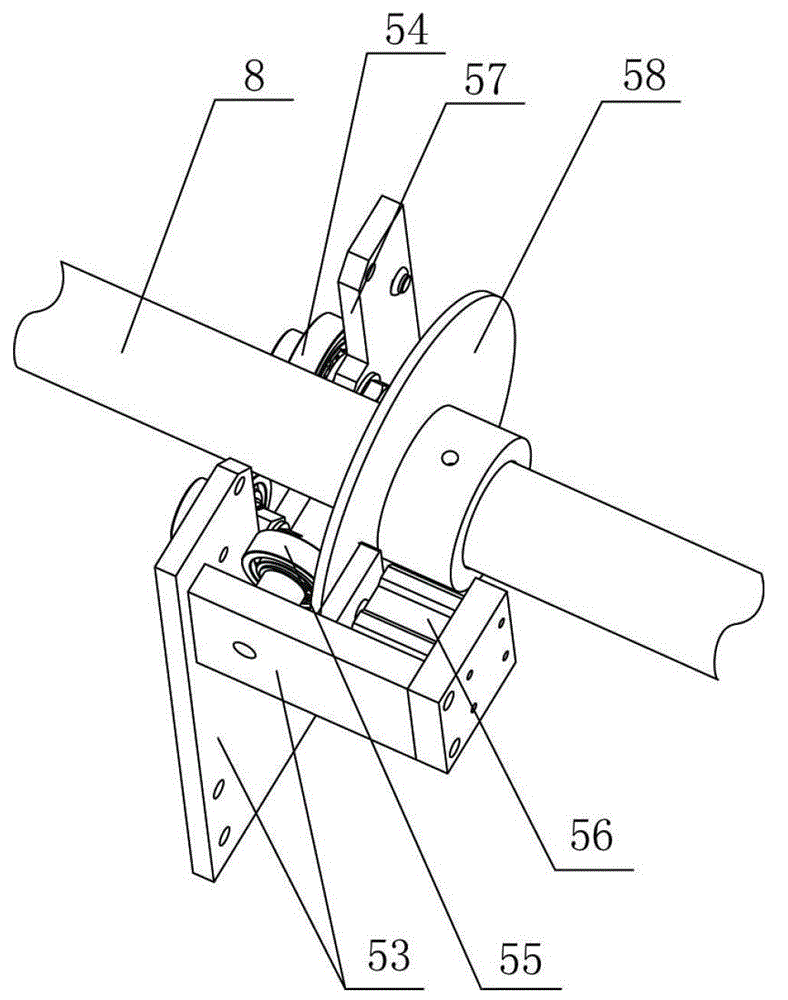

[0034] The machine tool platform 2 is fixed on the top of the machine tool frame 1 and the both sides of the machine tool platform 2 are provided with bed movable frame rails 6, the lower side of the machine tool platform 2 is provided with an electrical box 20, and the machine head 3 is fixed on the front end of the machine tool frame 1, Machine head 3 comprises machine head frame 7, braking device 43, yarn shaft 8, guide roller 9, hot blowing lifting cylinder 10, movable head track 13, movable head 11, and the top side of machine head frame 7 is provided with display screen 50 , the bottom side of the head frame 7 is provided with an air valve conversion box 21, the head frame 7 is fixedly connected with the machine frame 1 and the connection between the head frame 7 and the machine tool platform 2 is fixed with a yarn guide plate 12, and the yarn guide plate 12 A yarn pressing plate 51 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com