Hydraulically-driven variable-area T-shaped anti-rolling hydrofoil

A driving and variable technology, which is applied in the direction of using hydrofoils to reduce the movement of ships on the surrounding water surface, and can solve the problems of weak ship swaying ability, poor anti-rolling effect of hydrofoils, and increased fuel consumption, etc., to achieve The effect of reducing fuel consumption, increasing lift coefficient, and increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention are given below and described in conjunction with the accompanying drawings.

[0019] like figure 1 As shown, the upper end of the column 1 of the T-shaped hydrofoil is fixed on the bottom of the ship; the lower end is connected to the horizontal main wing 2; the column 1 is perpendicular to the horizontal main wing 2.

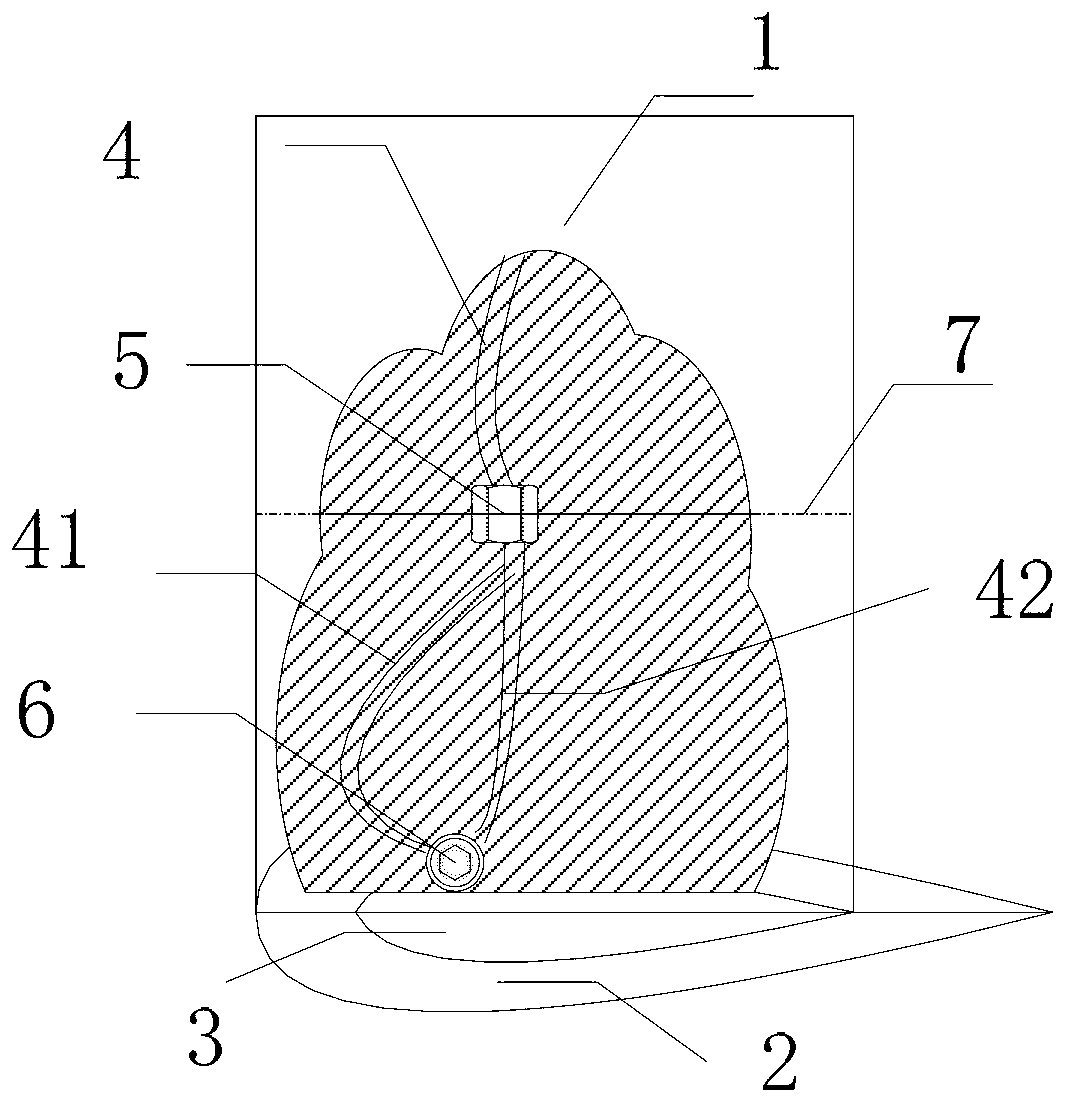

[0020] like figure 2 As shown, the middle part of the column 1 is provided with a sealing baffle 7, and the sealing baffle 7 is provided with an oil hole, and a pipe joint 5 is installed at the oil hole, and the oil pipe 4 is connected with the oil inlet pipe 41 and the oil return pipe 42 through the pipe joint. Horizontal main wing 2 and aileron 3 needn't be sealed; Actuating oil cylinder 6 and oil inlet pipe 41 and oil return pipe 42 all adopt waterproof parts. Horizontal main wing 2 and aileron 3 and column 1 bottom always work in water.

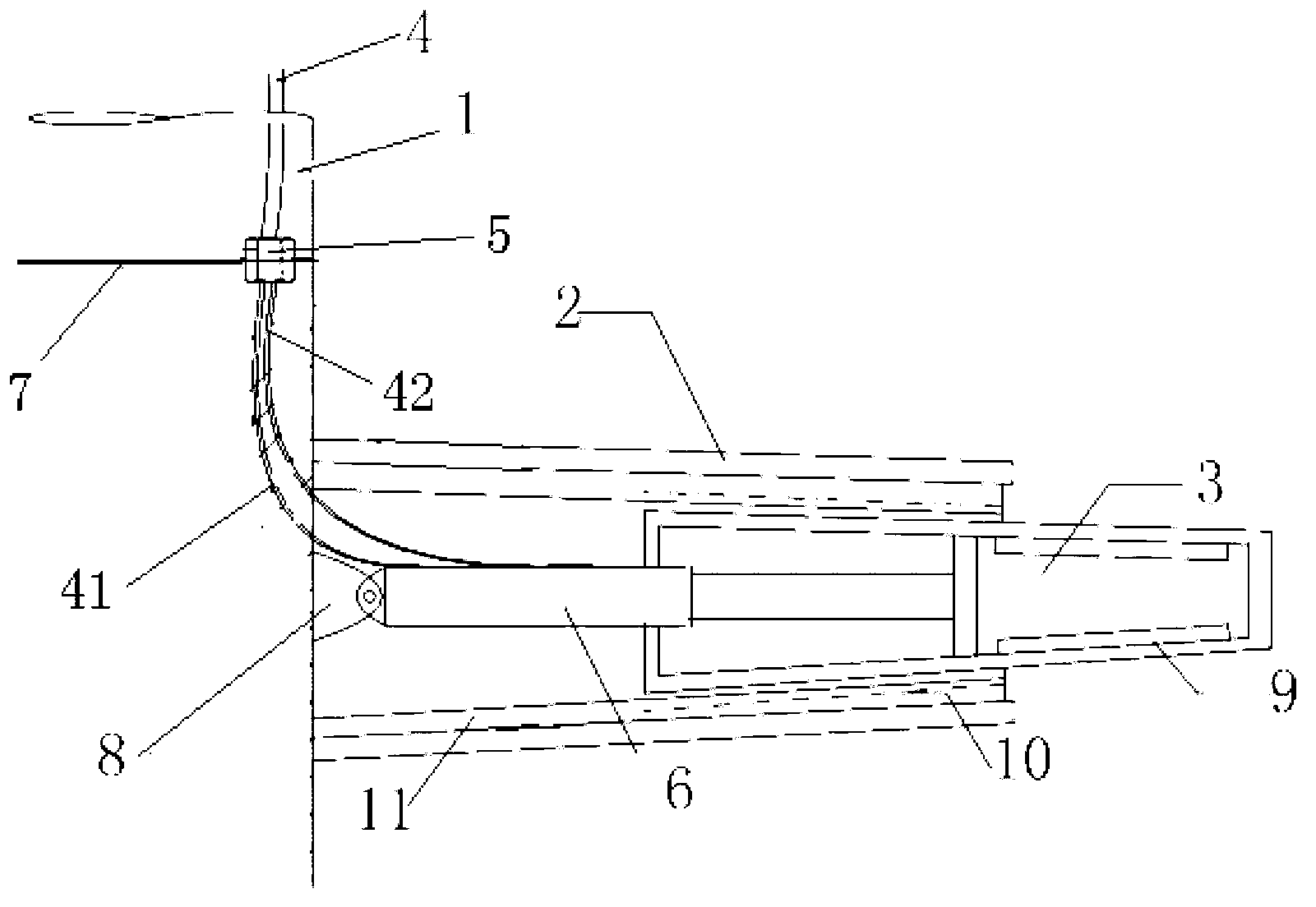

[0021] refer to image 3 and Figure 4 , in order to increas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com