Packaging machine for automatic forming of hexagonal section

An automatic forming and packaging machine technology, which is applied in the directions of packaging, transportation and packaging, and the type of packaging items, can solve the problems of few automatic packaging machines for slender bars, random large packaging, and high labor costs, achieving structural Simple, low labor intensity and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

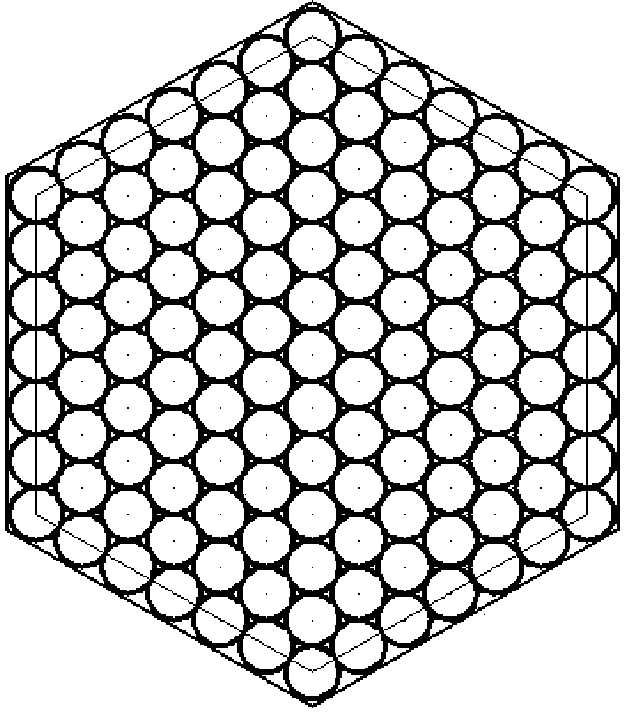

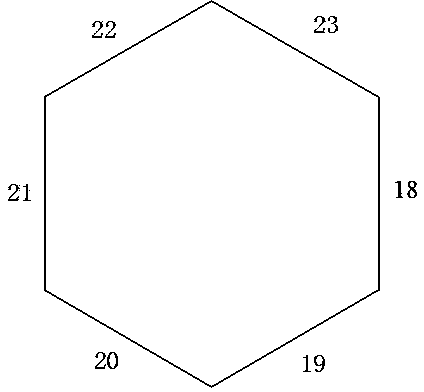

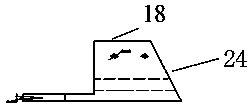

[0016] Such as Figure 1-8 As shown, the packaging machine includes a base 1, a bed saddle 2, a workbench 3, a bed saddle track 4, a bed saddle motor 5, a workbench track 6, a workbench motor 7, a left thin cylinder 8, a right thin cylinder 9, a left slide Table cylinder 15, left sliding table cylinder 16 and forming module 17, bed saddle track 4 is set on the top surface of base 1, bed saddle 2 is installed on bed saddle track 4 through bed saddle screw rod, bed saddle screw rod connects bed saddle motor 5 , the top surface of the bed saddle 2 is provided with a workbench track 6, the workbench 3 is installed on the workbench track 6 through the workbench screw rod, the workbench screw rod is connected with the workbench motor 7, and the left and right sides of the workbench 3 are respectively installed with left baffles 10 and the right baffle plate 11, the left thin cylinder 8 is installed on the left baffle plate 10, the right thin cylinder 9 is installed on the right baff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com