Patents

Literature

32results about How to "Large room for upgrade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

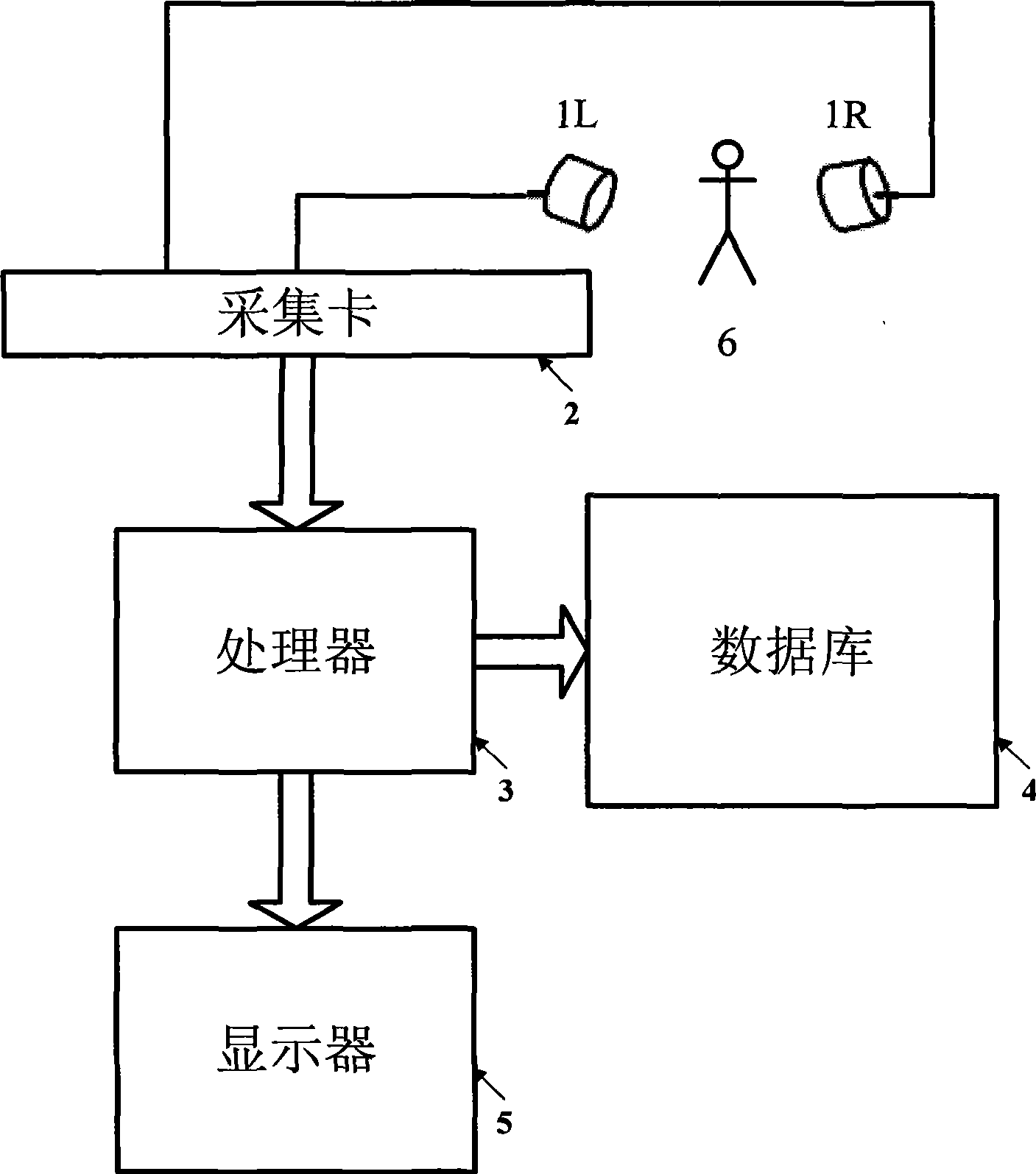

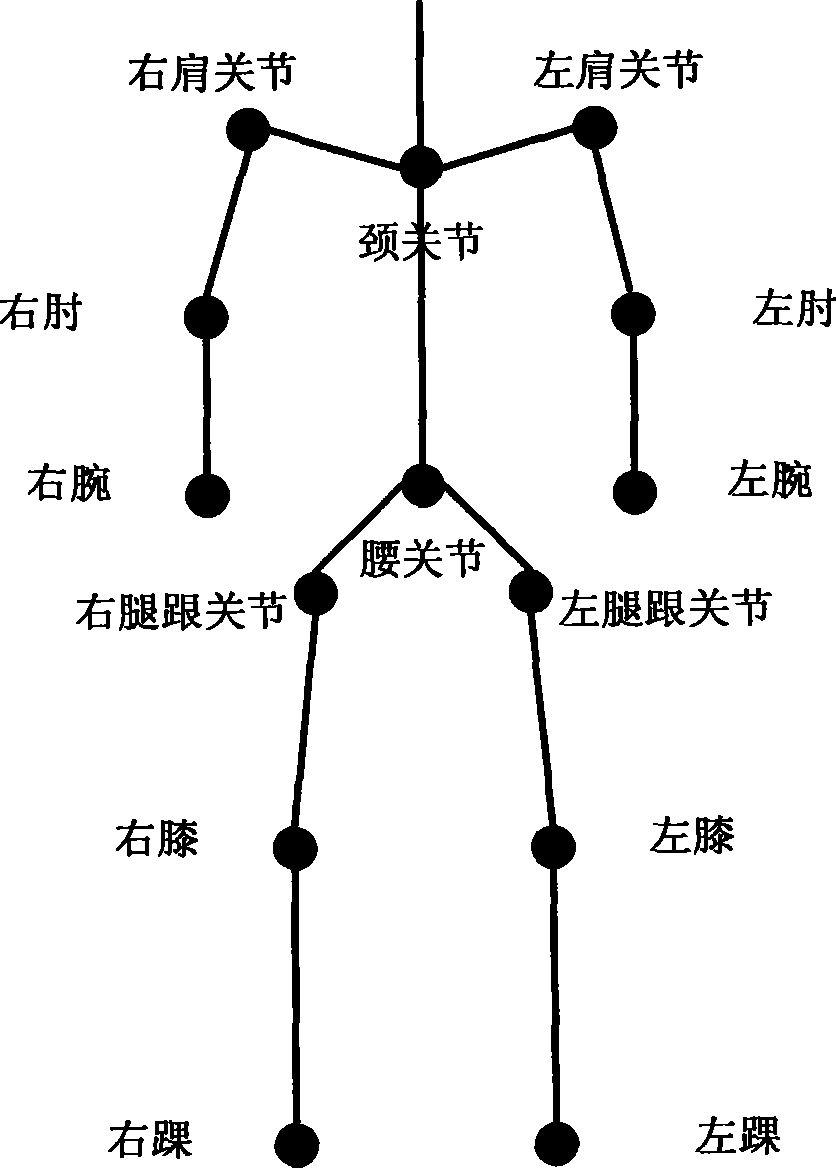

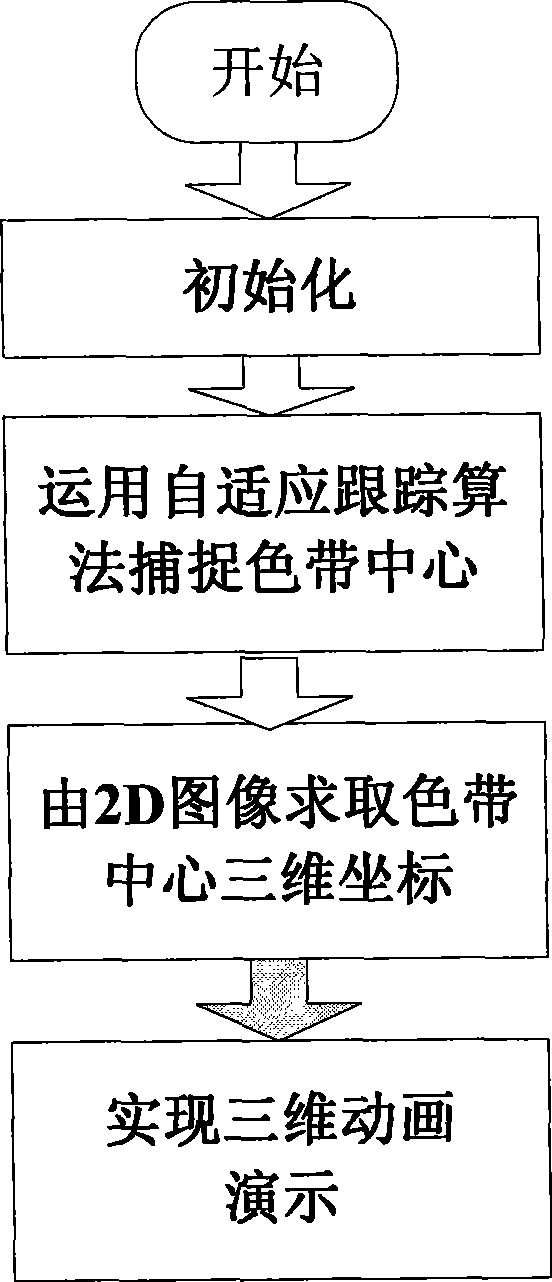

System and method for low cost motion capture and demonstration

InactiveCN101520902ALow costLarge room for upgradeImage data processing detailsAnimationAnimationDisplay device

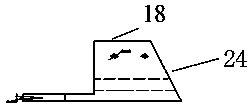

The invention relates to a system and a method for low cost motion capture and demonstration. A performer wears a suit of demonstration clothes provided with joint signalized points, and the demonstration clothes use black color as a ground color; each main joint is tied with ribbons with different colors as signalized points; a double-CCD camera acquires motion image information of the performer, and then transmits the acquired data to an embedded process through an image acquisition card; and the embedded processor captures the signalized points dynamically through a self-adapting algorithm, calculates three-dimensional coordinates of the signalized points through a binocular stereo vision technique, and stores the three-dimensional coordinates in a database, thus the reappearances of a skeleton model and three-dimensional animations are achieved on a display according to the coordinates in the database, and the current positions of the signalized points acquired by the system are exhibited intuitively for the convenience of debugging and demonstration.

Owner:SHANGHAI UNIV

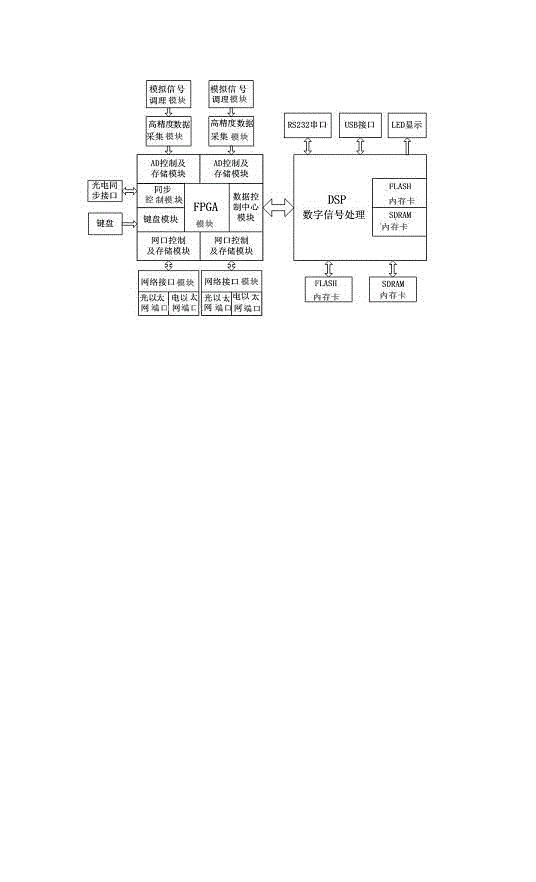

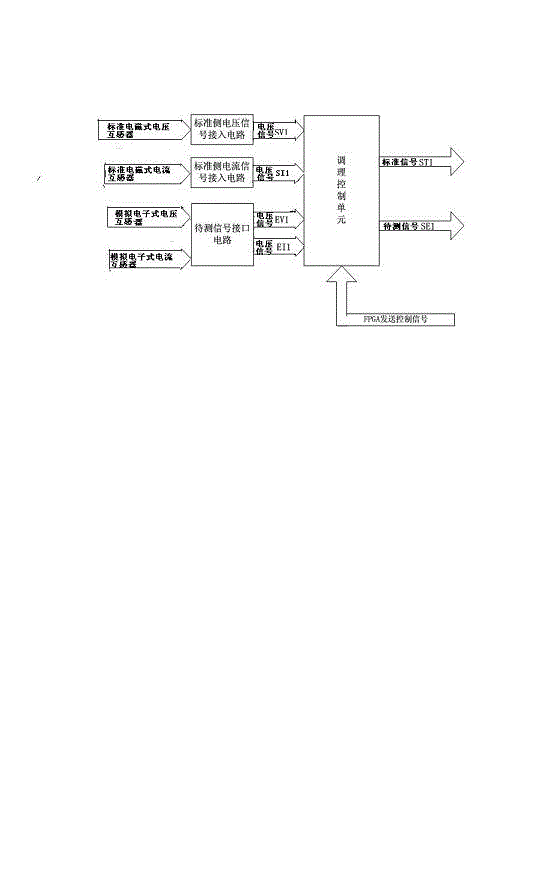

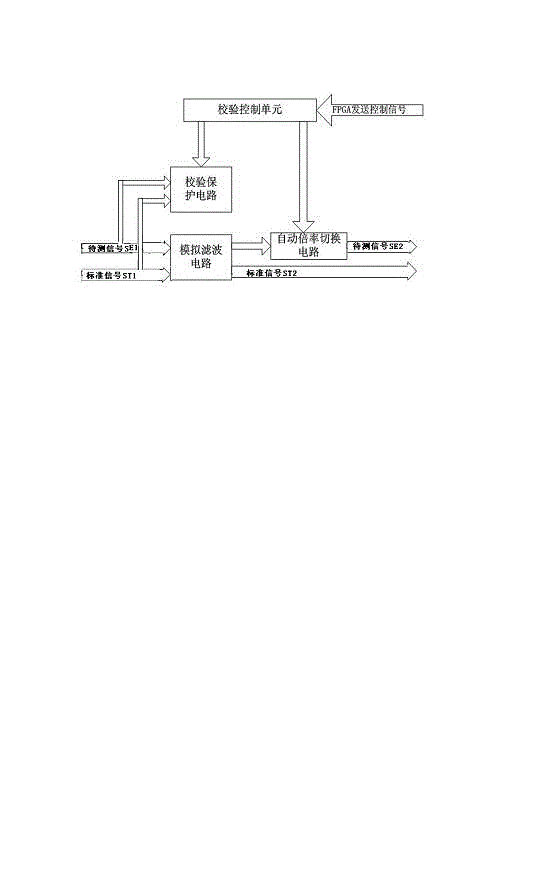

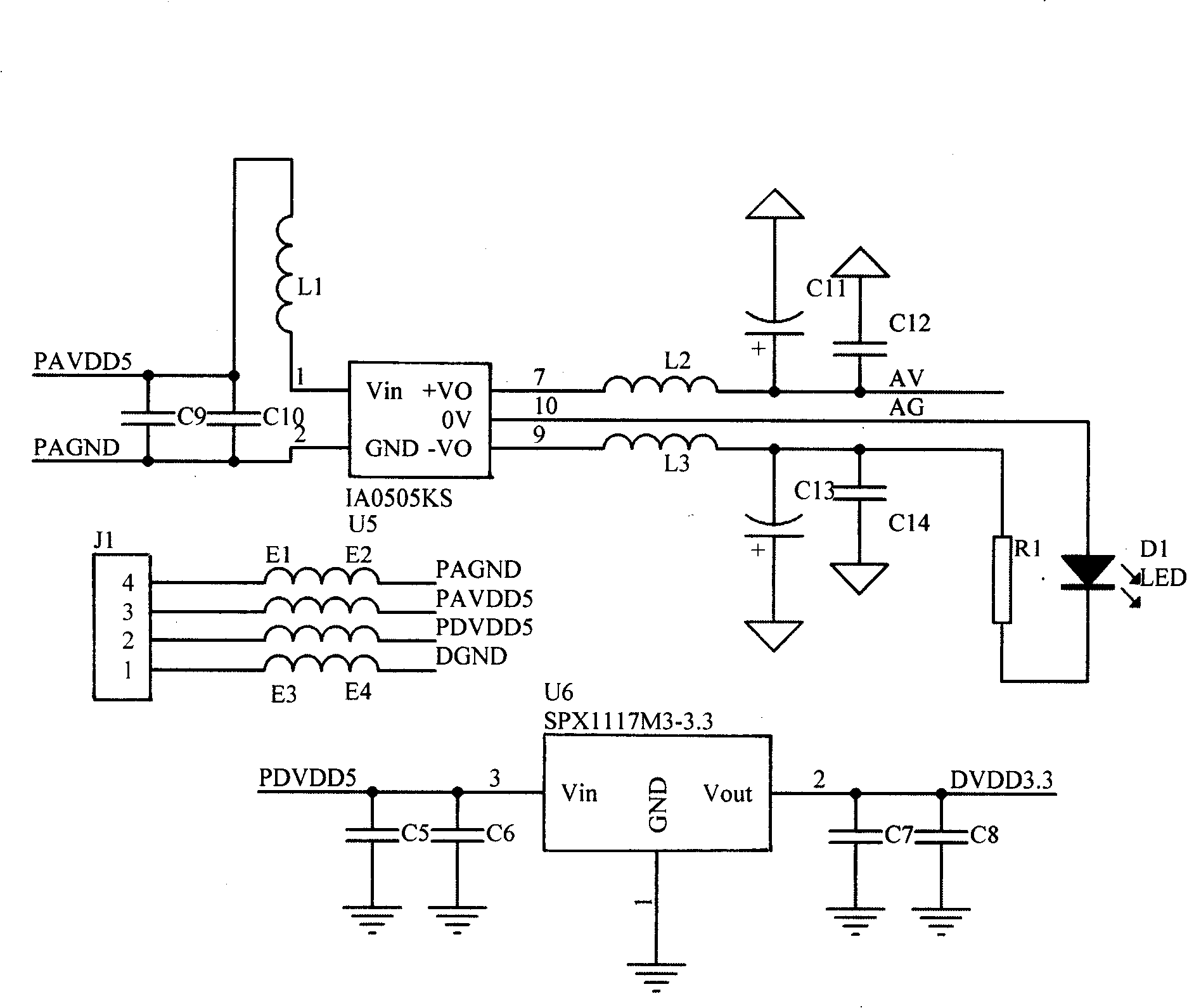

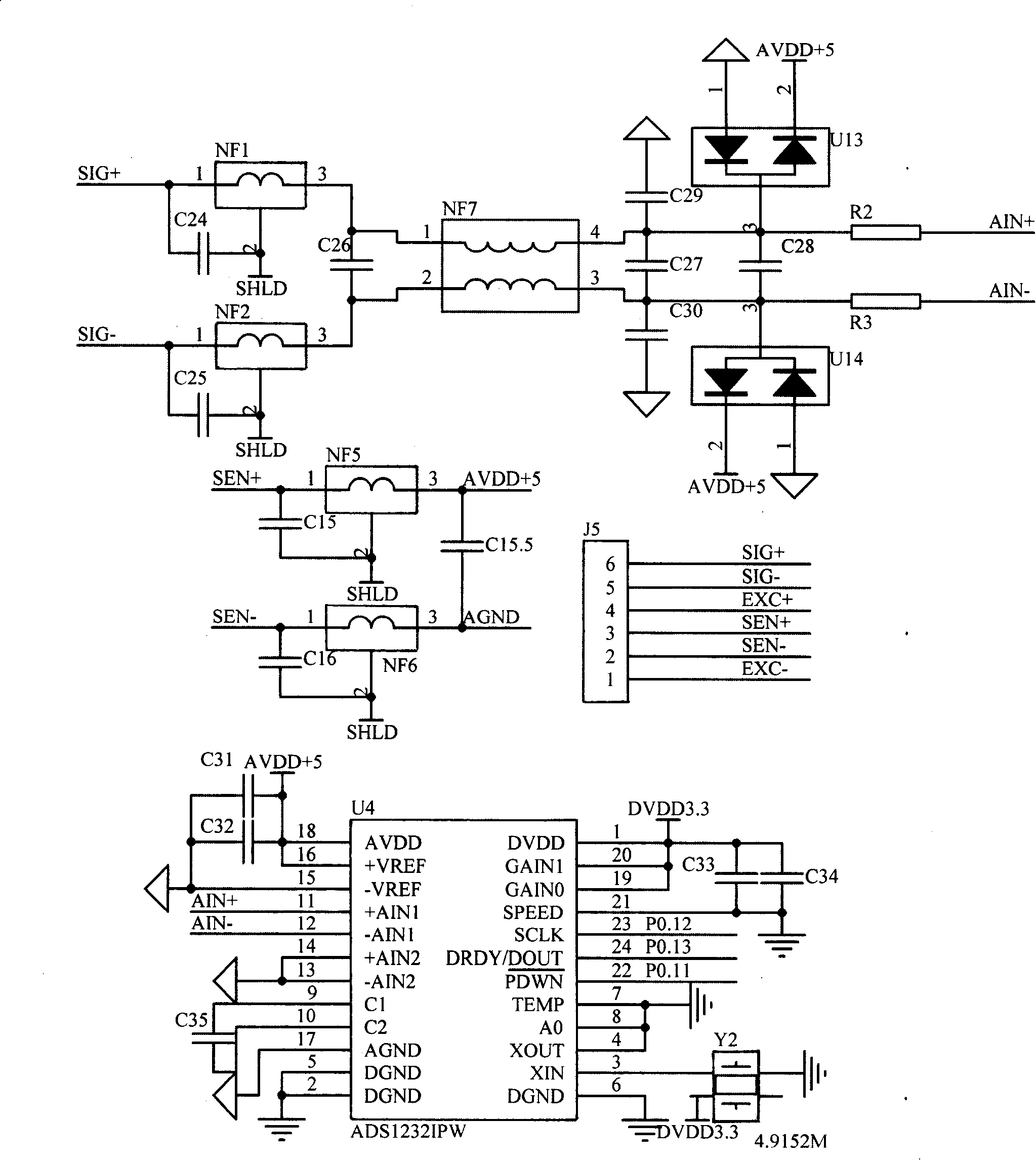

Multifunctional electronic transformer calibrator

InactiveCN103064051AExcellent logic control abilityFunctionalElectrical measurementsDigital signal processingTransformer

A multifunctional electronic transformer calibrator comprises an analog signal conditioning module, a high-precision data acquisition module, a network interface module, a synchronous clock module, a FPGA module, a digital signal processing and storage module, a display and keyboard module and a general standard interface module. The FPGA module comprises an AD control and storage module, a synchronization control module, a net port control and storage module and a data control center module. The multifunctional electronic transformer calibrator of the invention adopts a DSP+FPGA framework. Electronic transformer calibration equipment possessing a power factor angle measurement function and an error code detection function is realized. According to the equipment, an electromagnetic transformer can be taken as a standard transformer or the electronic transformer can be taken as the standard transformer. An analog electronic transformer can be verified and a digital electronic transformer can be verified too. The size is small. Operation is easy and on-site verification is convenient.

Owner:熊江咏

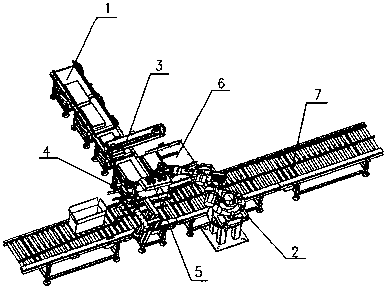

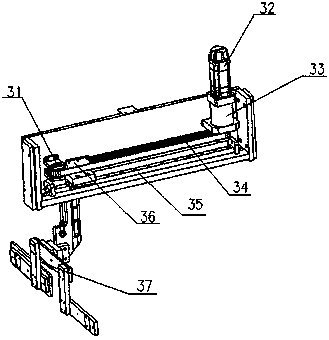

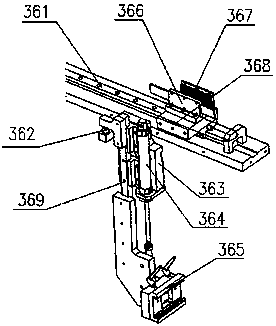

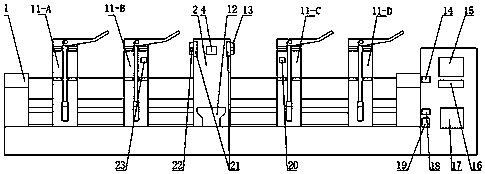

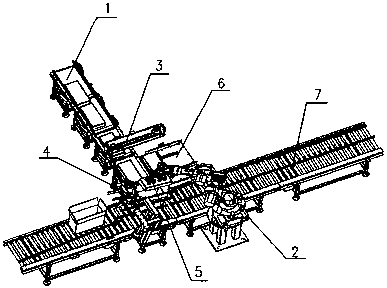

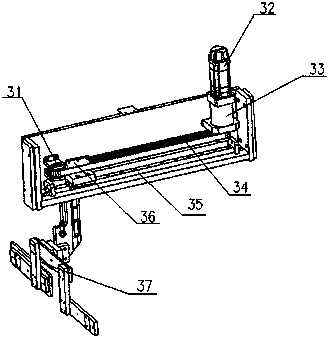

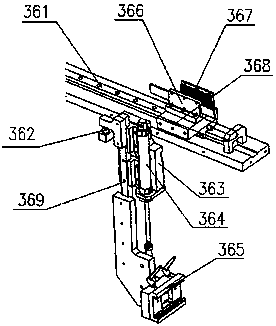

Multifunctional paper diaper robot box filling machine

The invention discloses a multifunctional paper diaper robot box filling machine. The robot box filling machine comprises a suction type box filling part and a clamping type box filling part, whereinthe suction type box filling part comprises a four-section feeding part, a six-axis box filling robot, a side pushing mechanism, a box opening mechanism, a sucker gripper, a suction platform and a roller conveying line; the clamping type box filling part comprises a four-section feeding part, a six-axis box filling robot, an arrangement mechanism, a clamping platform, a side pushing mechanism, a box opening mechanism, a clamping gripper and a roller conveying line. The multifunctional paper diaper robot box filling machine has the advantages as follows: the multifunctional paper diaper robot box filling machine has double functions, the suction type box filling form and the clamping type box filling form are combined, the application range of the box filling machine is greatly enlarged, and the production cost is reduced.

Owner:NANTONG UNIVERSAL MACHINERY

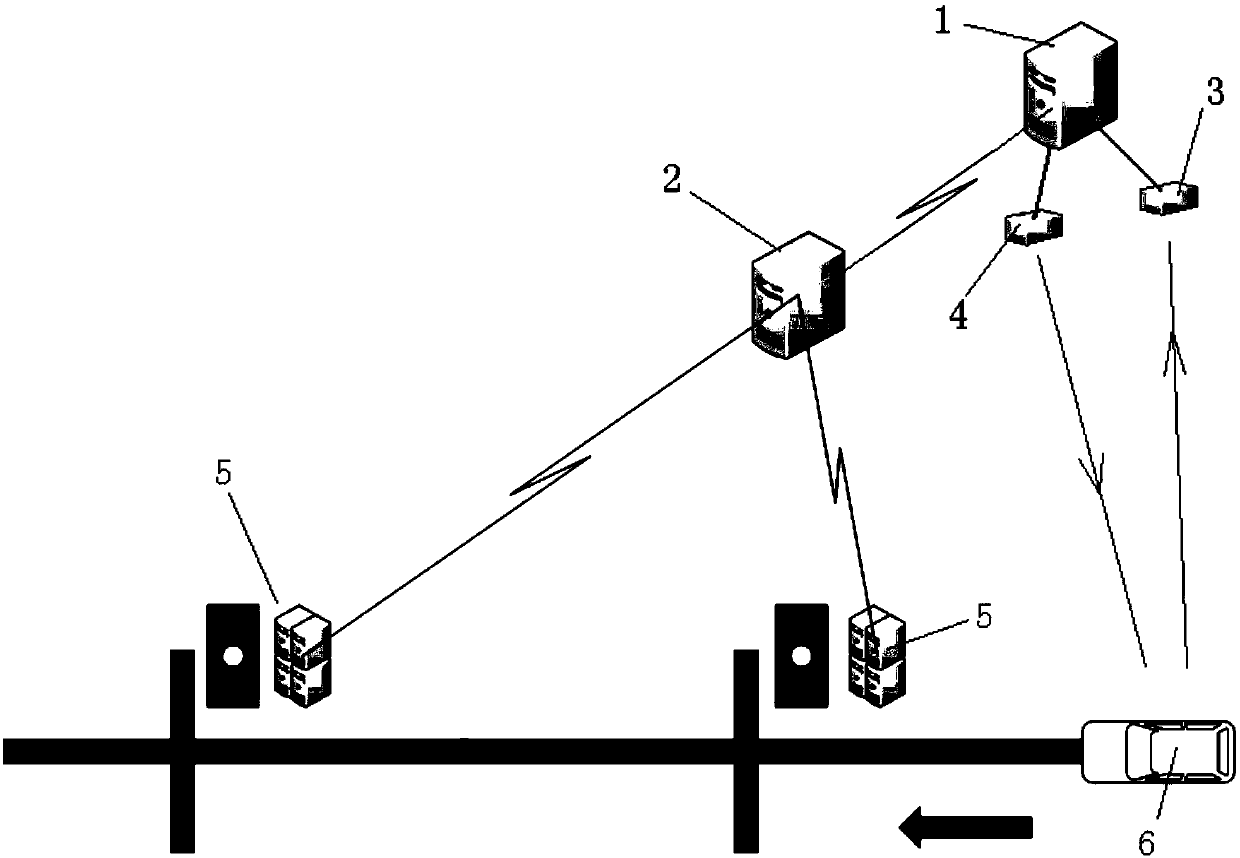

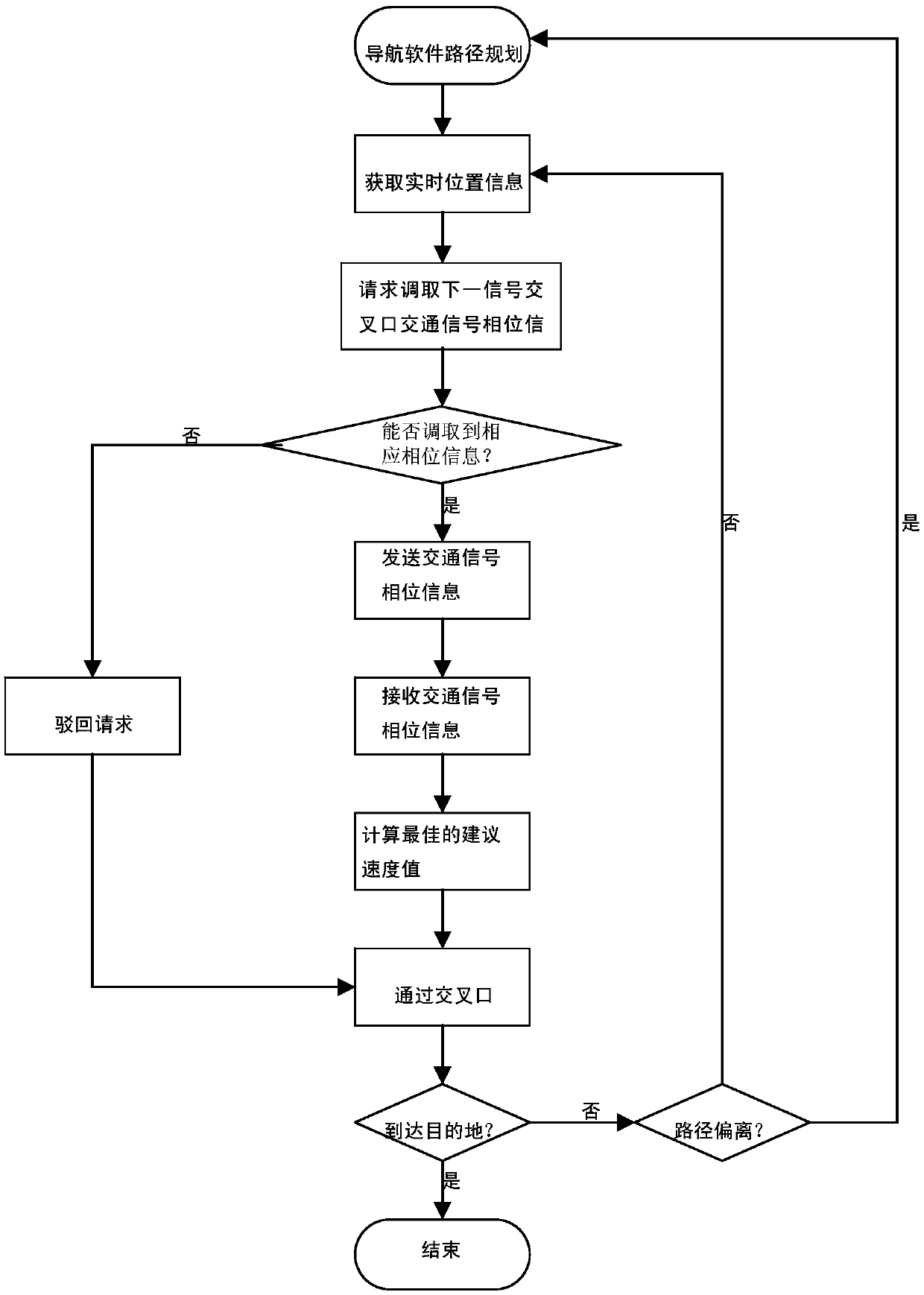

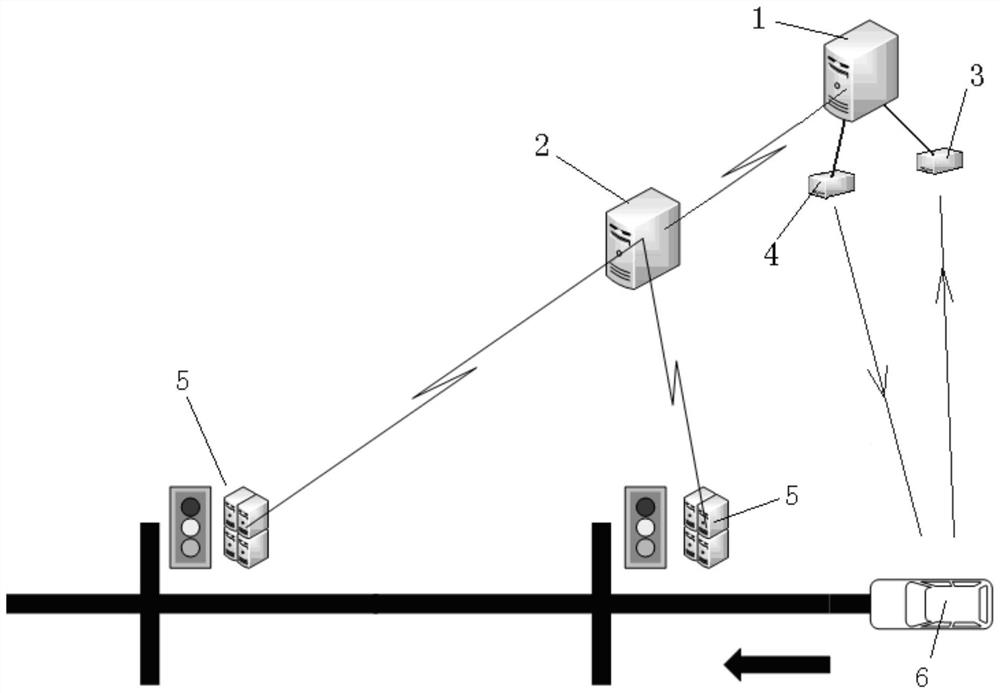

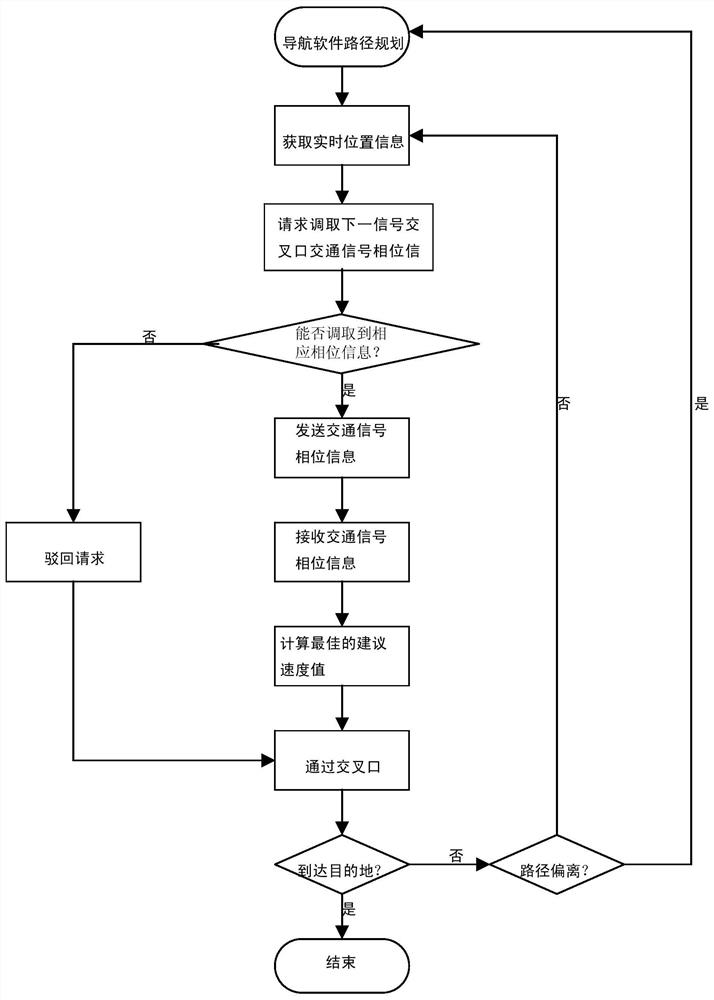

Speed guiding system and method that reduces signal intersection pausing

ActiveCN108682168AOptimal path planningReduce real-time speed guideArrangements for variable traffic instructionsTraffic signalEngineering

The invention provides a speed guiding system and method that reduces signal intersection pausing, and belongs to the traffic management and control technical field; the speed guiding system comprisesthe following parts: a traffic signal control subsystem used for controlling a signal lamp phase in real time according to real time traffic conditions, receiving traffic signal phase request information from a speed guiding device, and returning the corresponding traffic signal phase information to the speed guiding device; the speed guiding device arranged on a vehicle and used for communicating the traffic signal control subsystem in real time, sending the traffic signal phase information request to the traffic control subsystem with certain frequency via communication, receiving feedbackinformation from the traffic signal control subsystem, and providing a suggestion speed value for the vehicle according to the feedback information. The speed guiding system and method can solve the problems that an existing method cannot control to reduce the signal intersection pausing problem; the speed guiding system and method can be applied to intersection speed guiding.

Owner:HARBIN INST OF TECH

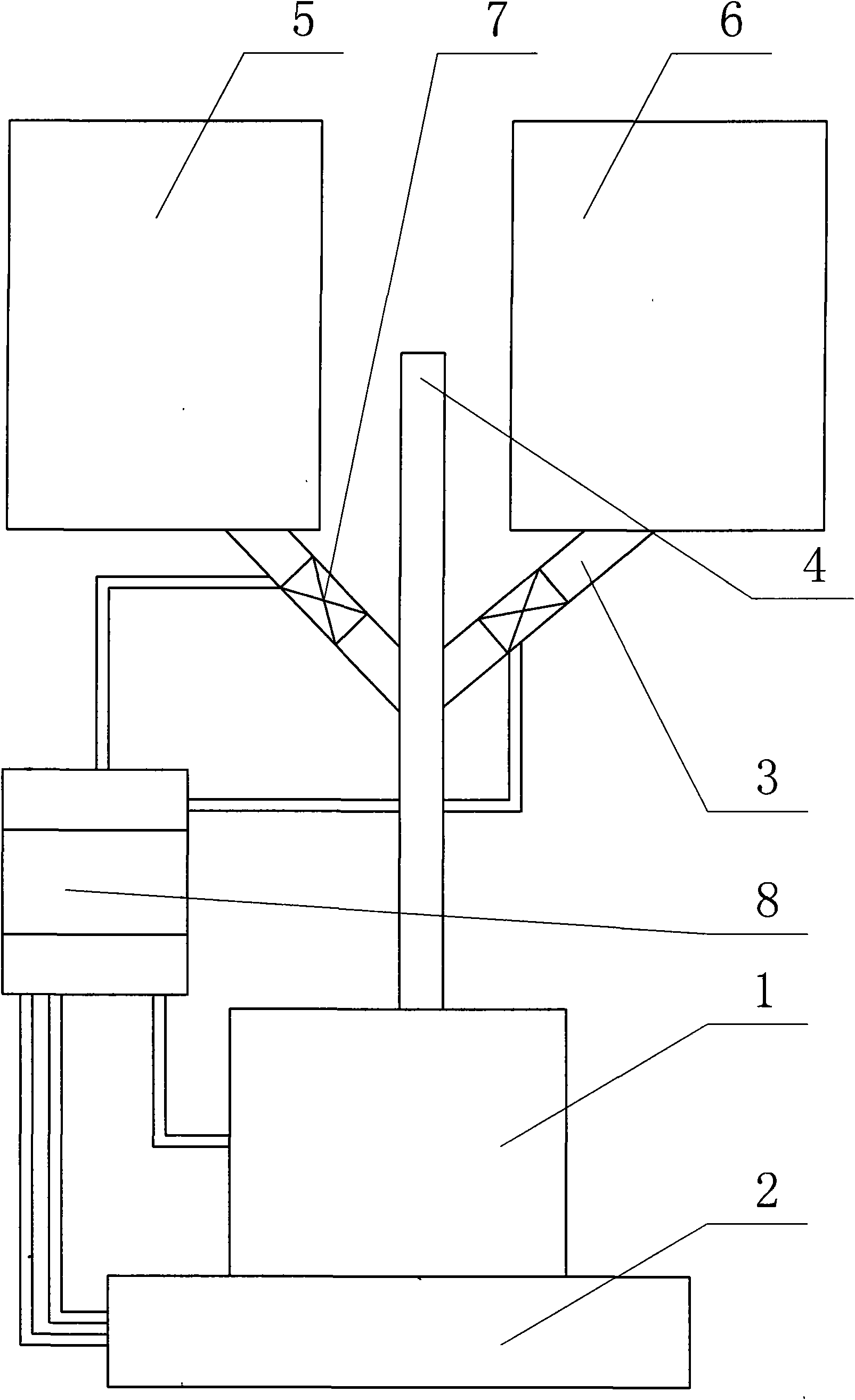

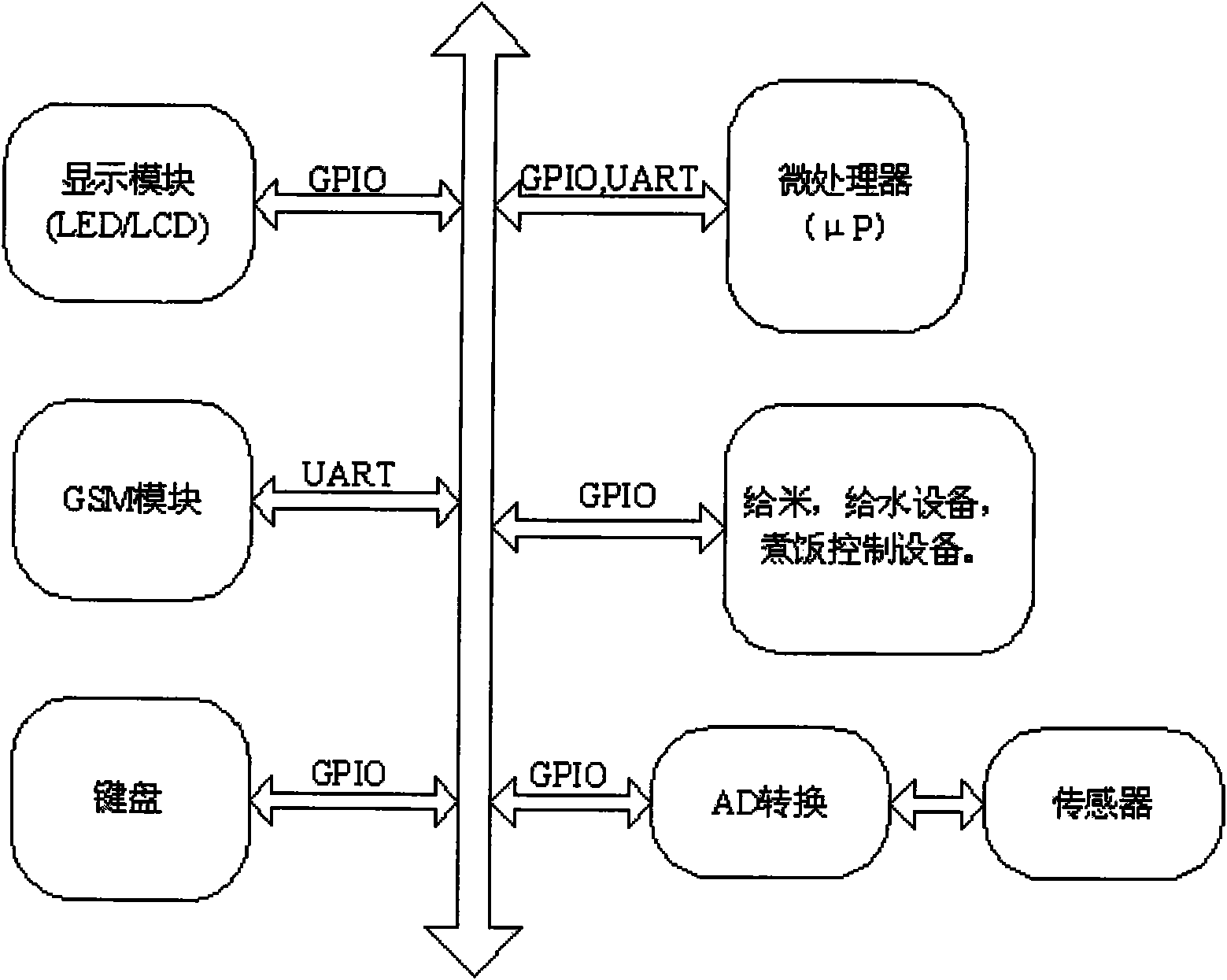

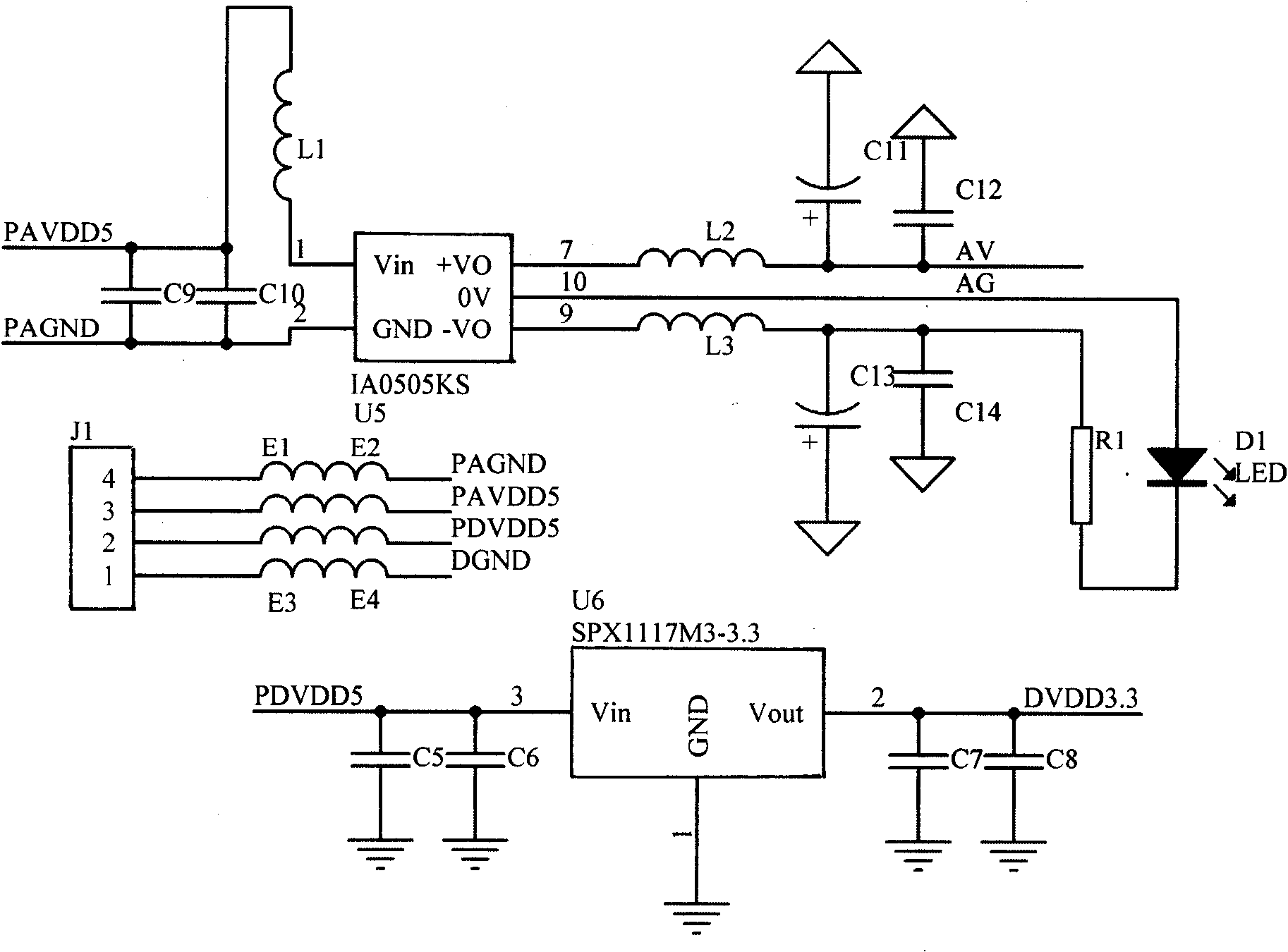

Intelligent cooking robot and cooking method

InactiveCN101574231ARealize intelligent controlConducive to uniform standardsCooking vesselsProgramme control in sequence/logic controllersWater storageProcess engineering

The invention relates to an intelligent cooking robot and a cooking method, aiming at overcoming the defect that the market of household appliances develops slowly at present. The intelligent cooking robot comprises a cooking device (1) which is provided with a pressure sensor base (2) and connected with a conveying passage (3) and an exhaust passage (4), wherein the conveying passage is respectively connected with a water storage container (5) and a rice storage container (6) and provided with a valve (7); and the valve, the cooking device and the pressure sensor base are respectively connected with a main control panel (8). The intelligent cooking robot is an intelligent cooking device.

Owner:HARBIN UNIV OF SCI & TECH

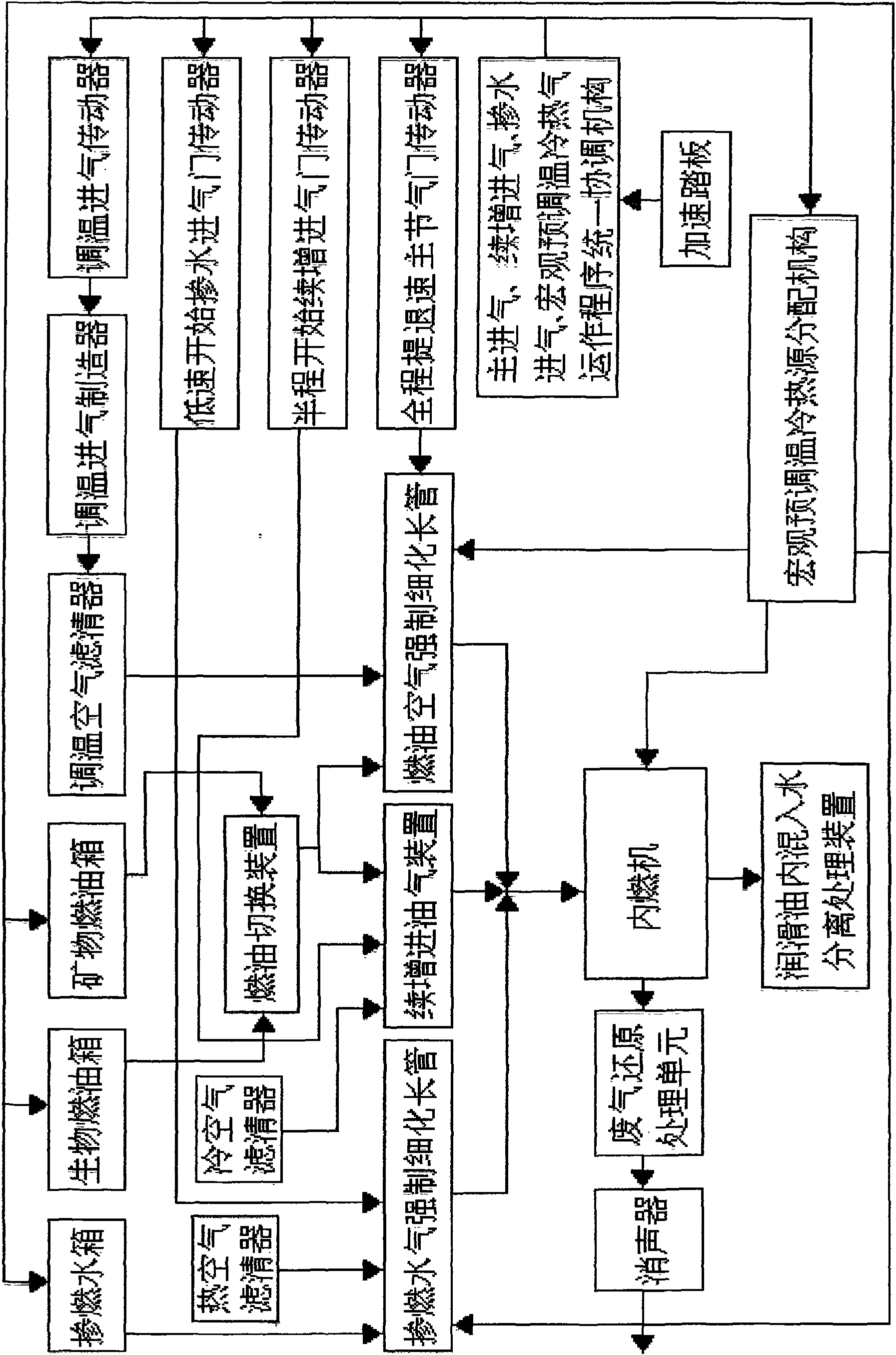

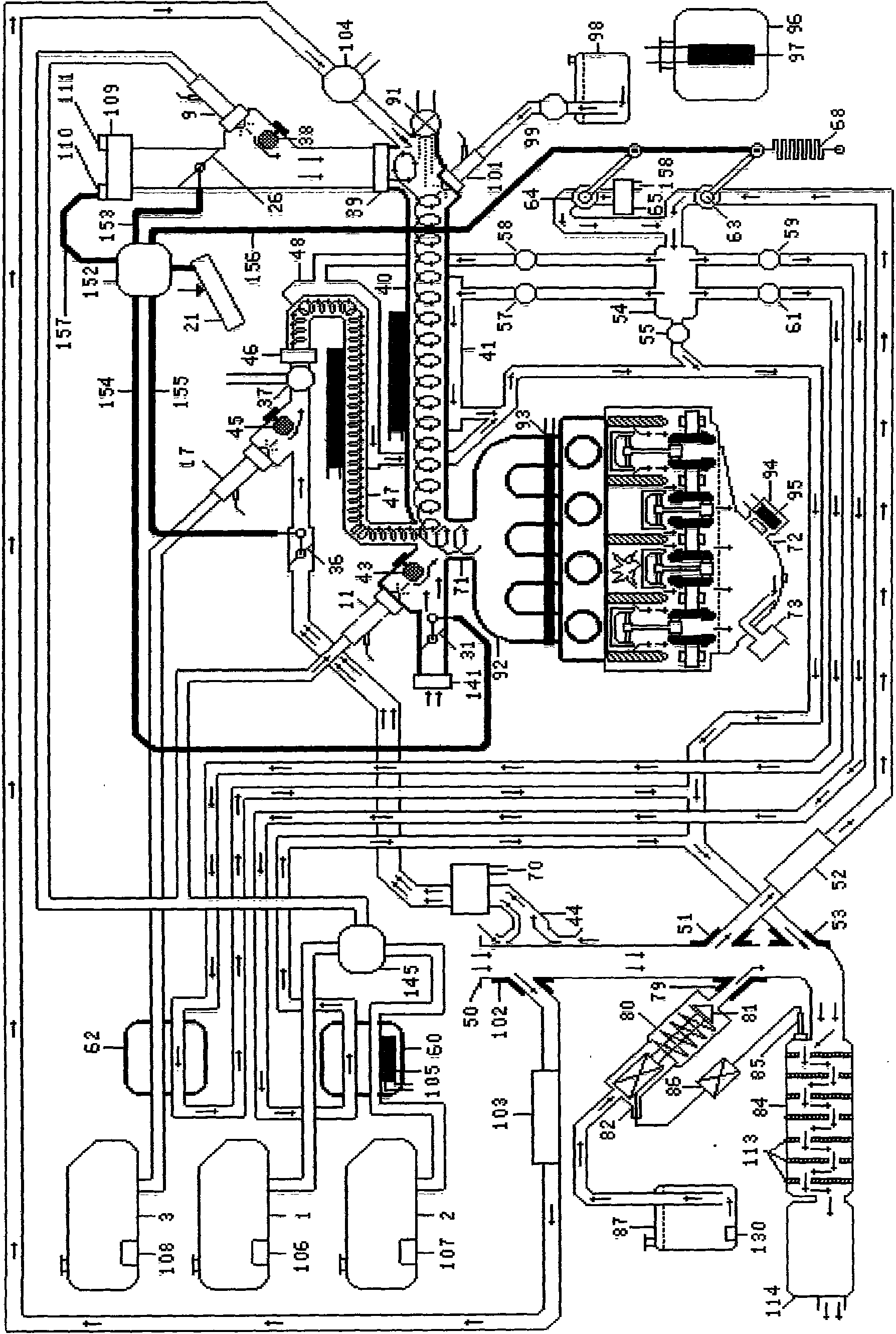

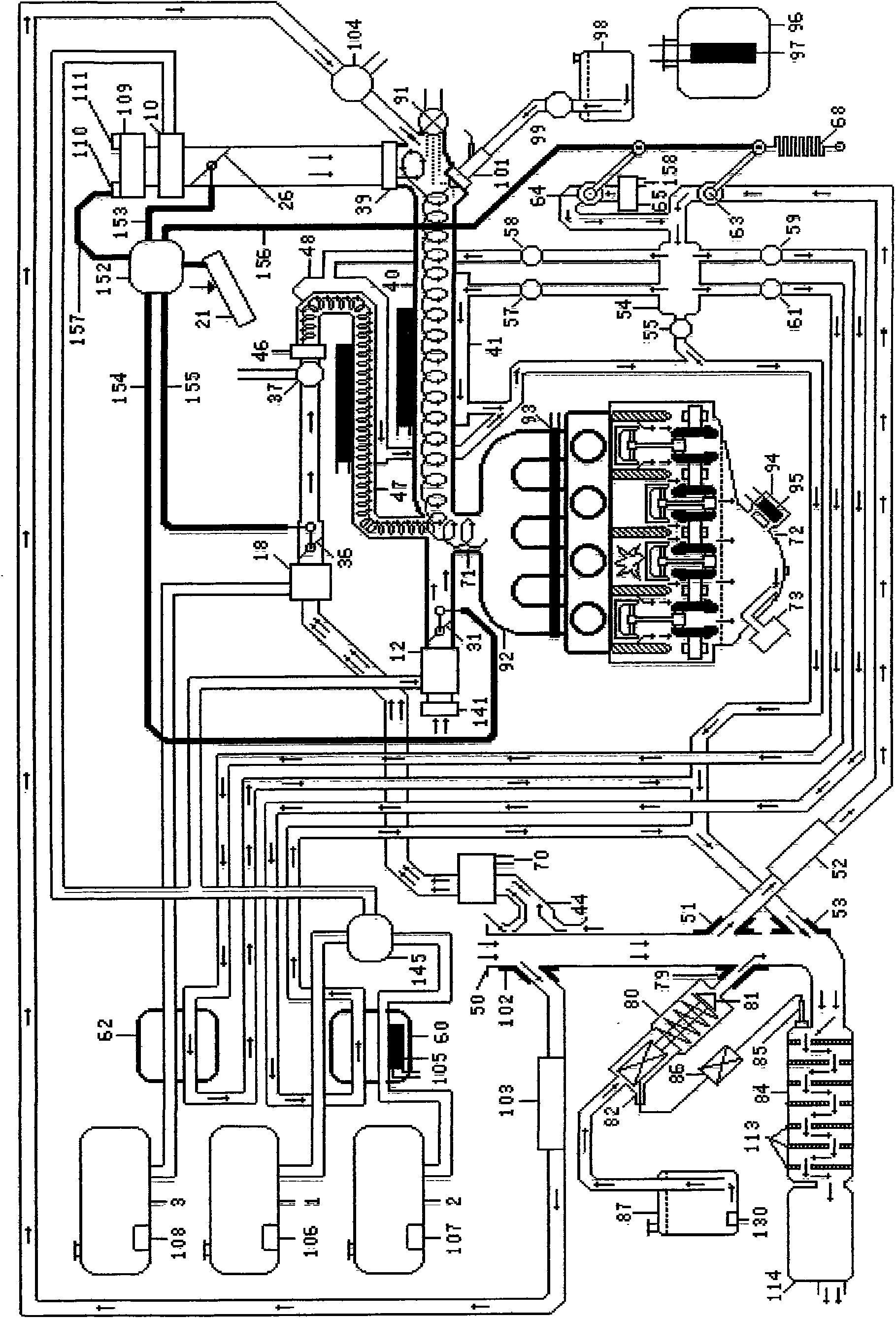

Engine energy-saving and emission-reducing system coordinated by heat pipe and cold pipe and working method thereof

InactiveCN101644208AReduced discharge resistanceEasy dischargeNon-fuel substance addition to fuelInternal combustion piston enginesCombustionExternal combustion engine

The invention relates to an engine energy-saving and emission-reducing system coordinated by a heat pipe and a cold pipe, which comprises an energy-saving and emission-reducing system of an internal combustion engine and the energy-saving and emission-reducing system of an external combustion engine, wherein, the energy-saving and emission-reducing system of the internal combustion engine comprises the internal combustion engine, a temperature-conditioning mineral fuel tank and a thick long swirling flow thin unit; and the energy-saving and emission-reducing system of the external combustion engine comprises the external combustion engine, a temperature-conditioning blending water tank and a water gas forced thinned long pipe. The working method comprises the working method of the energy-saving and emission-reducing system of the internal combustion machine and he working method of the energy-saving and emission-reducing system of the external combustion machine. The system has the advantages that the principle is simple and easy to develop and most of parts can directly select the existing standard parts for being used after simple transformation of the parts; the aggregate role of various technologies can sufficiently thin mixed gas, greatly reduce working temperature, improve the key technology which can greatly improve the geometric compression ratio and lead an oil-saving index to be about 50%; and the various technologies can be comprehensively applied for obtaining the energy-saving and emission-reducing ultra-high index, and the single technology therein can be independently used for obtaining the medium energy-saving and emission-reducing index with a small amount of investment.

Owner:段洪池 +3

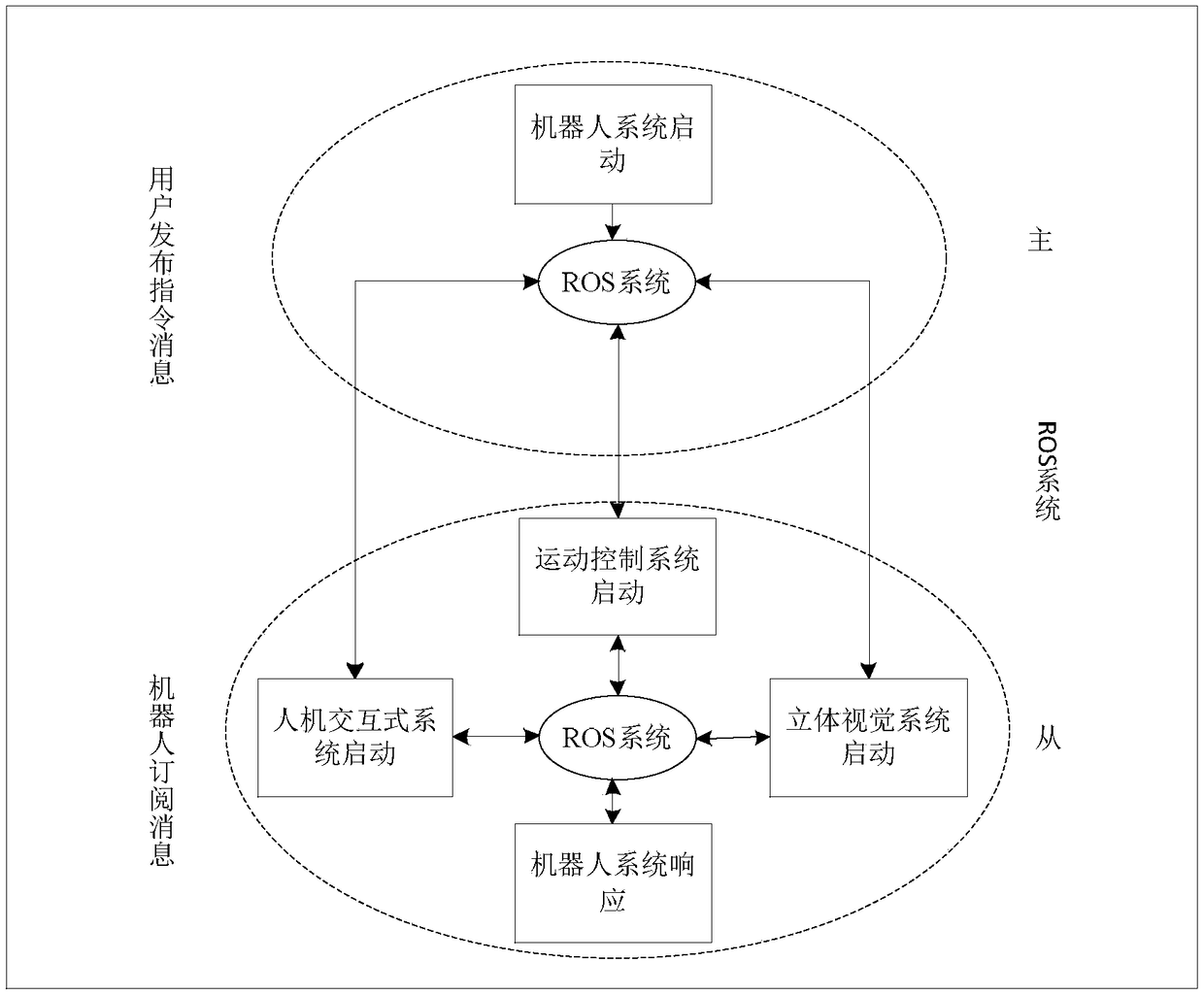

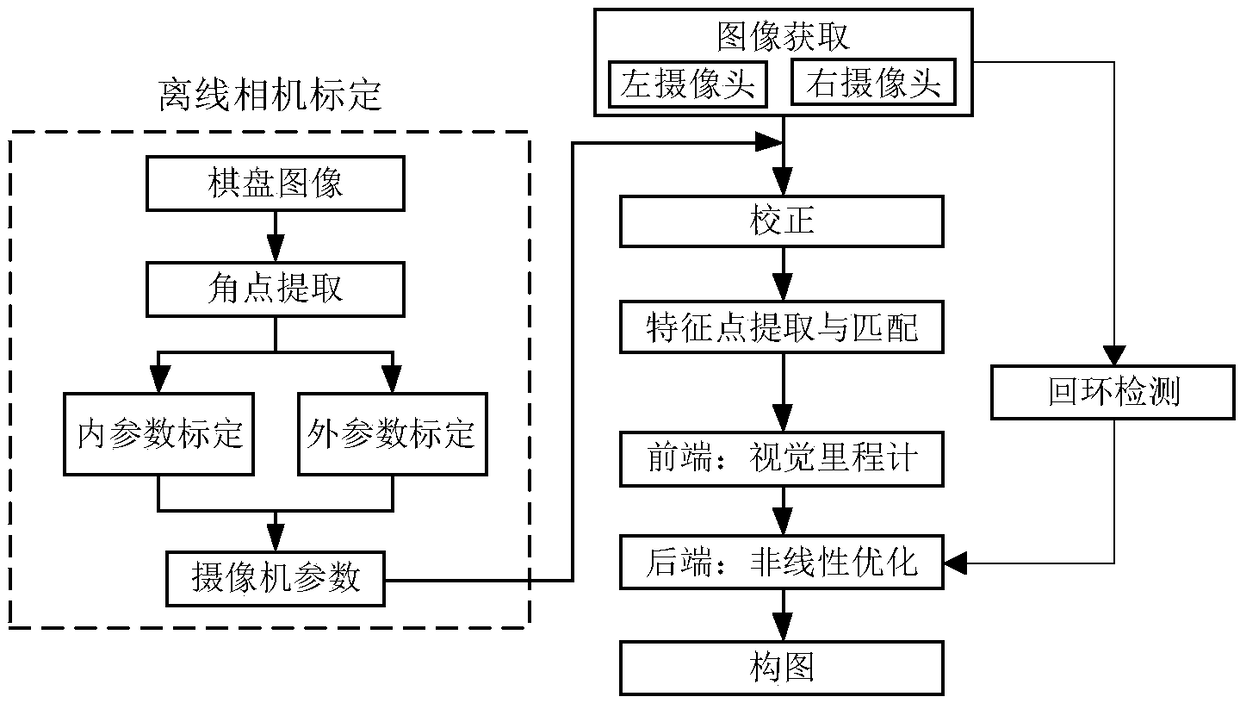

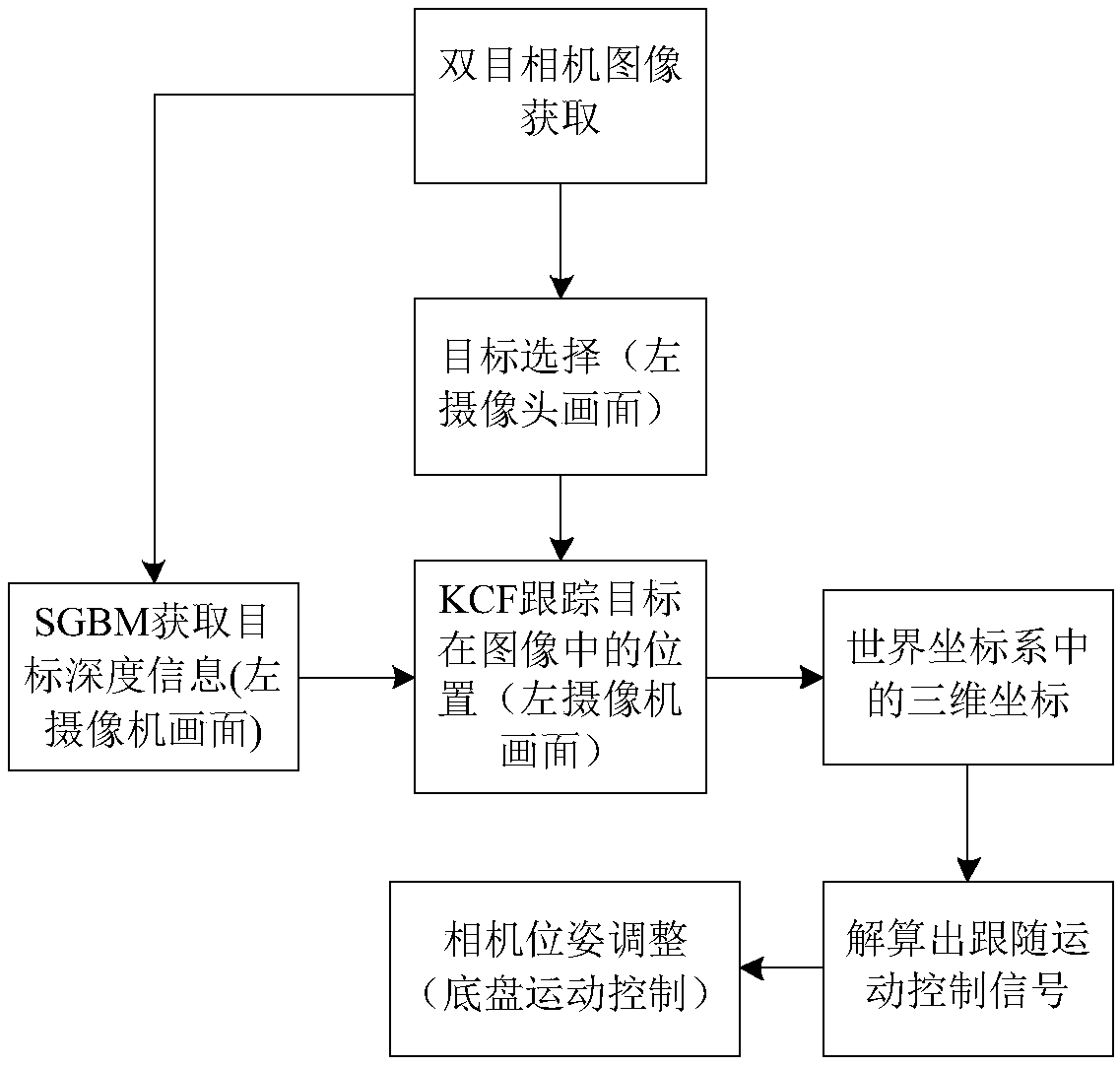

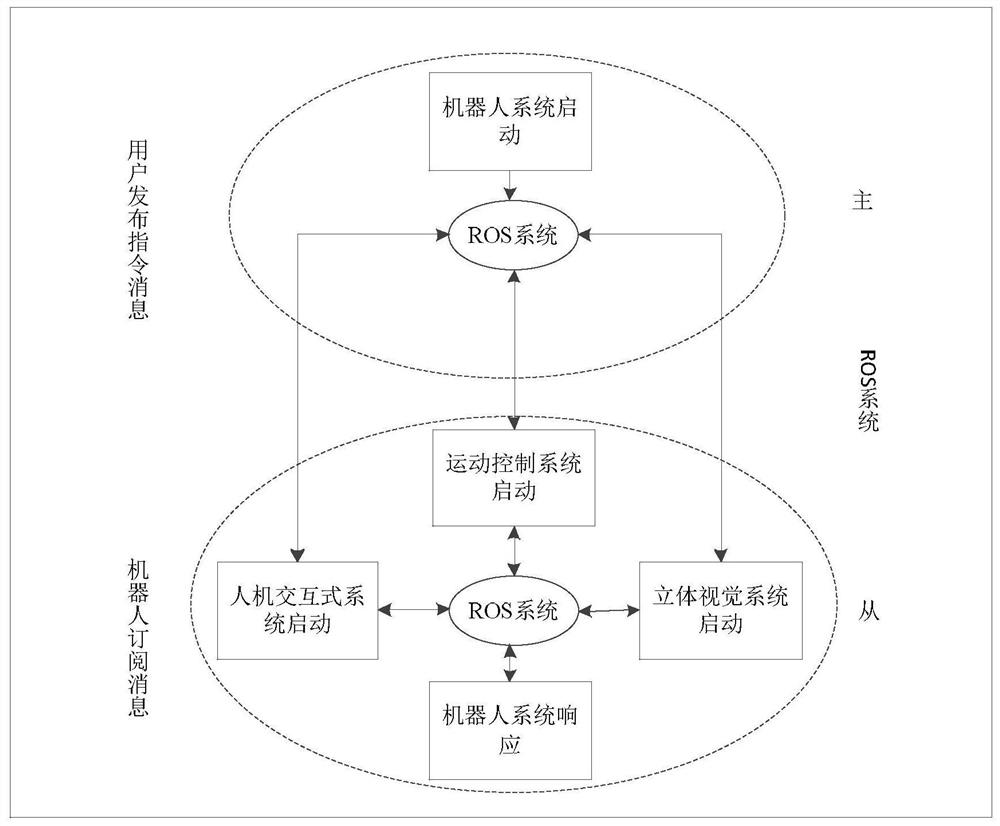

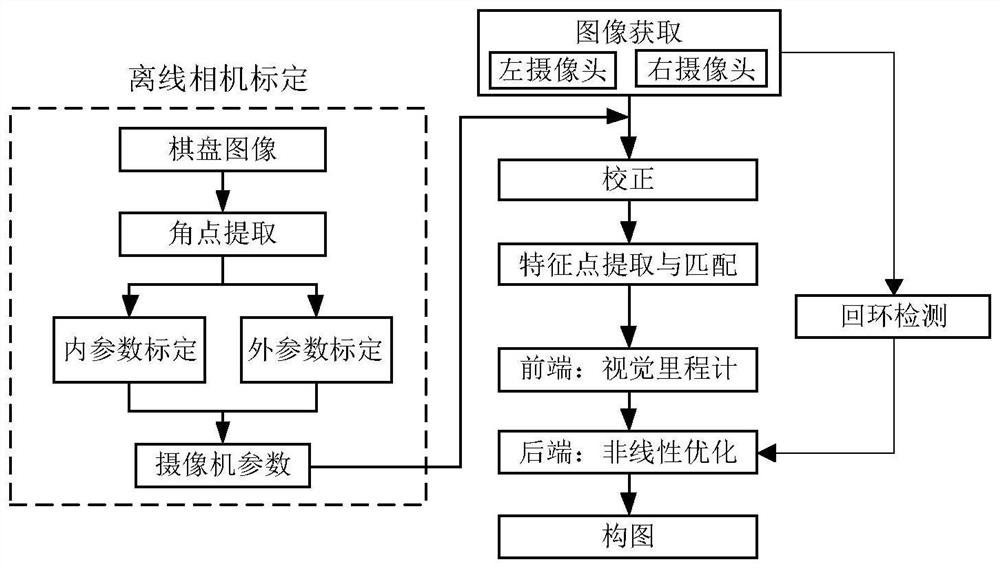

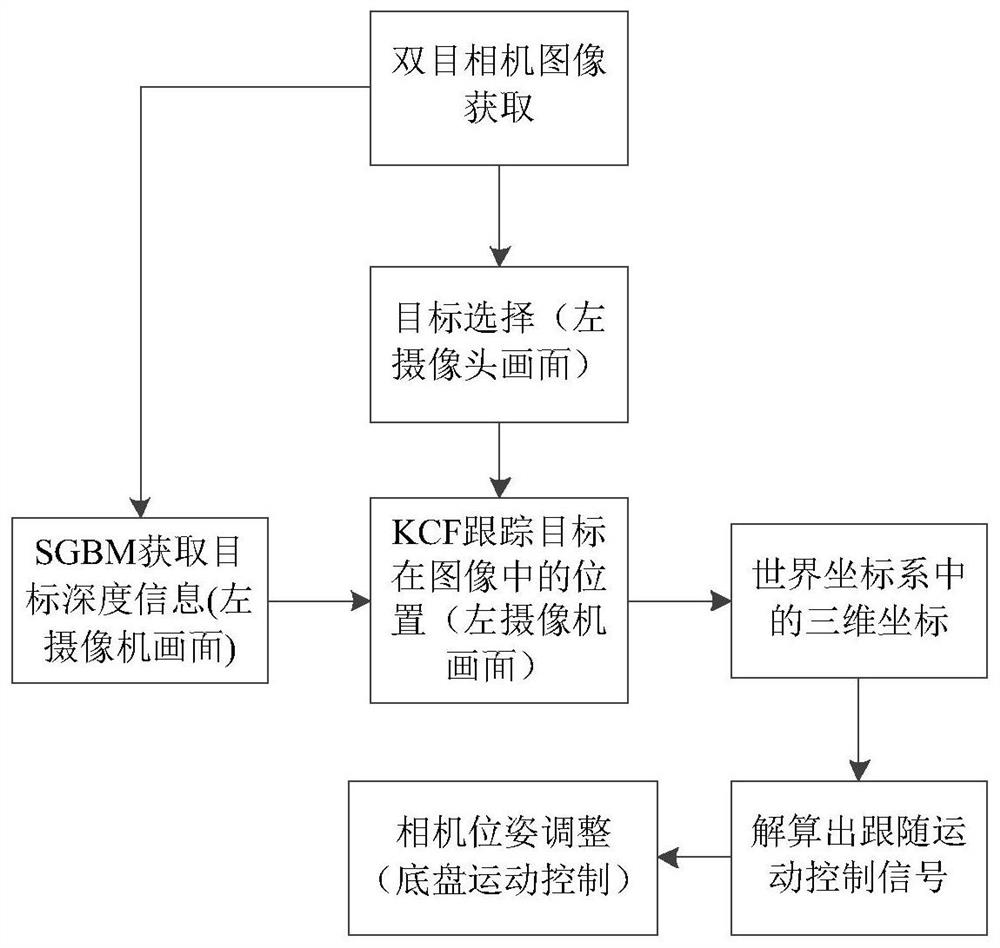

Intelligent detachable mobile robot system based on stereoscopic vision and control method

ActiveCN108646759AMaximize UtilizationHighly integratedPosition/course control in two dimensionsInformation transmissionControl system

The invention discloses an intelligent detachable mobile robot system based on stereoscopic vision and a control method. By combining stereoscopic vision,an interactive system and a motion control system,a mobile robot conveniently and rapidly knows the environment under the unfamiliar environment,various functions are achieved on the basis of man-machine interaction,and various tasks are completed under the assistance of motion control. Compared with a traditional robot,stereoscopic vision and the interactive system are combined,so that the defects of information obtaining quality and quantity can be overcome,and the problem of unipolarity of information transmission is solved,and the system has the advantages of man-machine interaction,environment understanding and the like. The problemthat an integrated robot can only work in one background to achieve intelligent operation is detachably solved,and the system is convenient to use,low in cost and easy to popularize.

Owner:WUHAN UNIV OF SCI & TECH

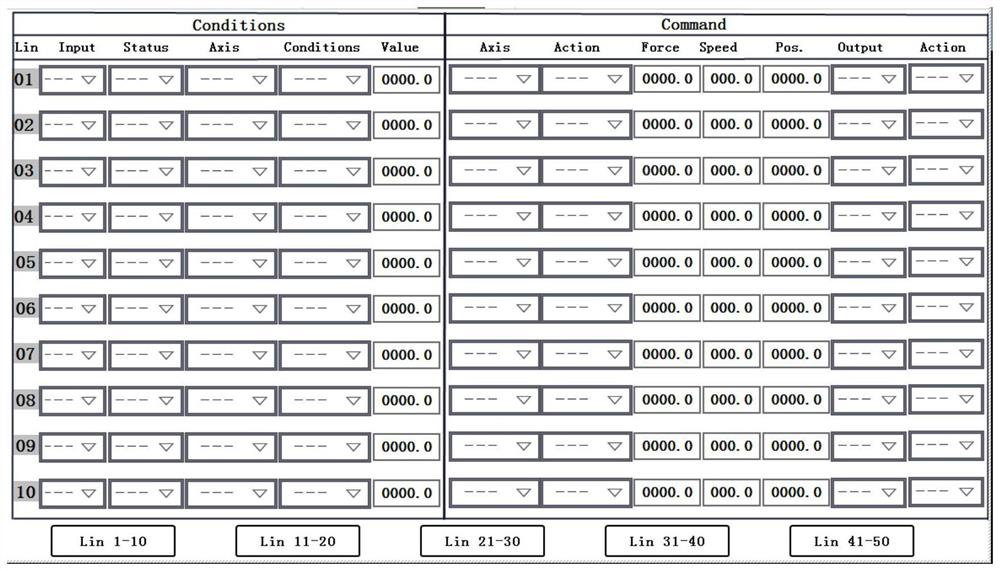

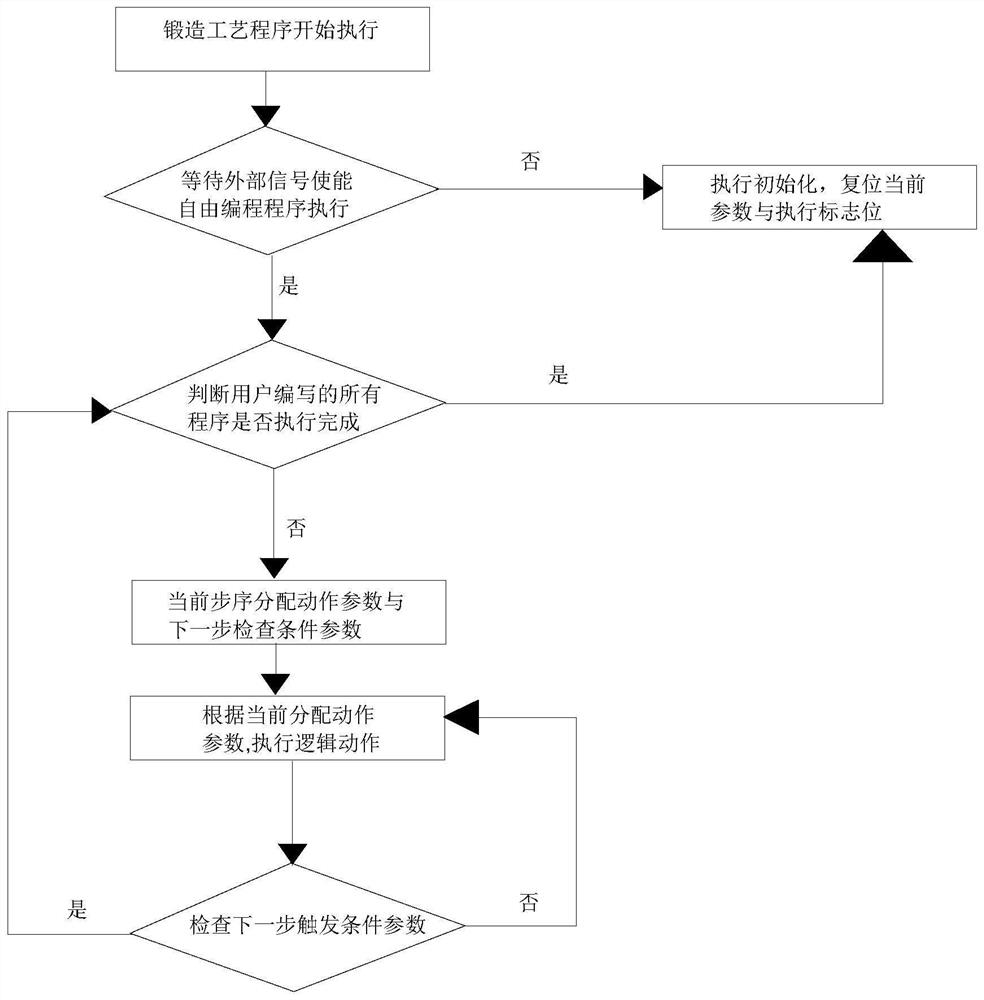

Programming method of forging process

InactiveCN112198843AIncrease flexibilityIncreased flexibility of useTotal factory controlProgramme total factory controlDiscrete programmingModularity

The invention relates to a programming method of a forging process. A heavy forging hydraulic press is decomposed into a plurality of modules according to the function, wherein the modules include a sliding block, a centering module, a workbench, a die signal, an auxiliary oil path, an auxiliary gas path, an automatic interface and the like. In the PLC, discrete programming of technological actions of the hydraulic forging press is completed according to modular objects, a single object can be driven to complete the actions, and then programming of technological free calling is completed in the PLC. Whether the action condition of each object is finished or not is checked, and parameters are distributed automatically to the sliding block, the centering part, the workbench, the die signal,the auxiliary oil path, the auxiliary gas path and the automatic part of the forging press; modularized and digitized parameters in the PLC are displayed on the HMI in a visualized mode, an operator can carry out freely programing according to the requirements for the technology, mold signals and automation, so that the requirement for the technology of the operator is lowered, the flexibility ofequipment is improved, and the time for equipment upgrading and technology improvement is saved.

Owner:TIANJIN TIANDUAN PRESS CO LTD

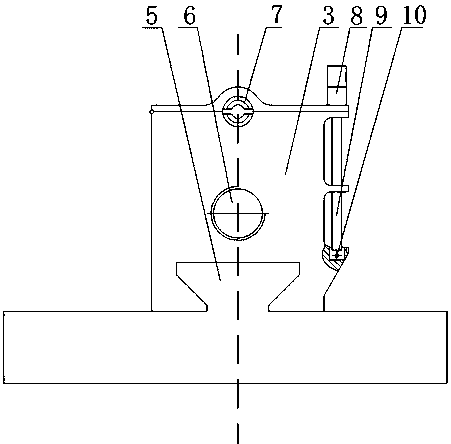

Automatic PPR pipe fusion-welding robot and fusion-welding method

The invention relates to an automatic PPR pipe fusion-welding robot and a fusion-welding method, which belong to the field of pipe fusion-welding and intelligent control, and aim to solve the problemsthat the manual fusion-welding of a PPR pipe is affected by the manual operation strength, a pipe propelling angle, the environment temperature, the processing time and other factors. The automatic PPR pipe fusion-welding robot comprises a base, wherein a die head clamping unit capable of heating different types of die heads is arranged in the middle of the upper part of the base; pipe clamping units are arranged on two sides of the die head clamping unit; fixtures are arranged on the pipe clamping units and are used for clamping pipes with different specifications; a laser transmitter and alaser receiver are arranged on the fixtures; and a single chip microcomputer drives a screw rod to feed along a guide rail, so that the automatic fusion-welding operation with the best fusion-weldingtemperature, heating time, hot-melting depth and fusion-welding time is realized. According to the automatic PPR pipe fusion-welding robot and the fusion-welding method provided by the invention, theautomatic fusion-welding of pipes and pipe fittings with different specifications can be realized, and the fusion-welding is carried out at the best time, temperature and position, the reliability offusion-welding is ensured, and the fusion-welding efficiency is improved.

Owner:HARBIN UNIV OF SCI & TECH

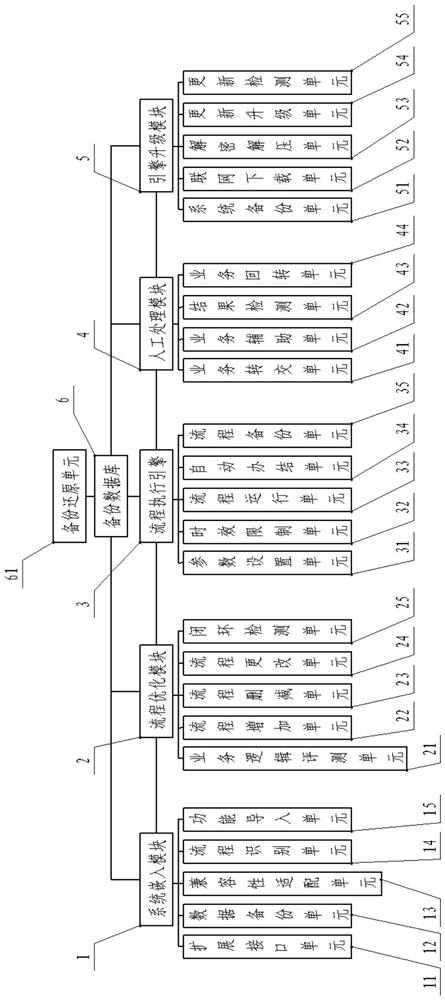

Intelligent response process engine system for intelligent dialogue system

ActiveCN113298494ARealize update and upgradeVariety of expansion methodsCustomer relationshipOffice automationResponse processDialog system

The invention provides an intelligent response process engine system for an intelligent dialogue system, which comprises a system embedding module, a process optimization module, a process execution engine, a manual processing module and an engine upgrading module, and is characterized in that the system embedding module expands and embeds the intelligent response process engine system into the intelligent dialogue system; and is used for expanding and upgrading the intelligent dialogue system, the process optimization module is used for optimizing an intelligent process unit according to a business process of an original intelligent dialogue system, and the process execution engine is used for operating a process framework formed by the process optimization module. The manual processing module is used for carrying out manual processing on abnormal conditions in the operation process of the intelligent response process engine system, the engine upgrading module is used for updating and upgrading the intelligent response process engine system, and in a word, the invention has the advantages of being complete, convenient to use, large in upgrading space and the like.

Owner:陕西合友网络科技有限公司

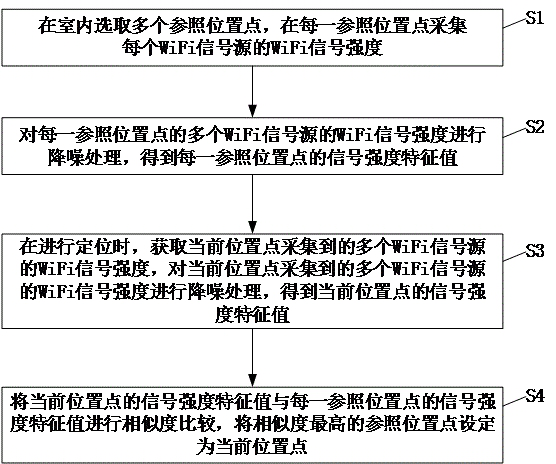

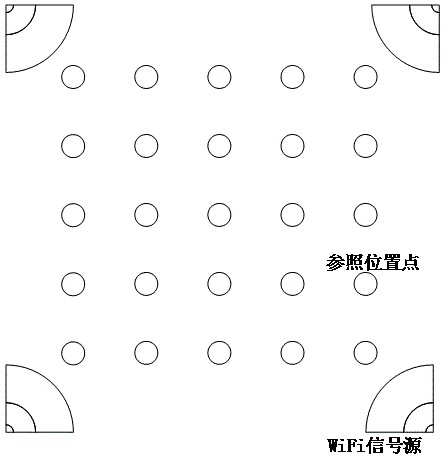

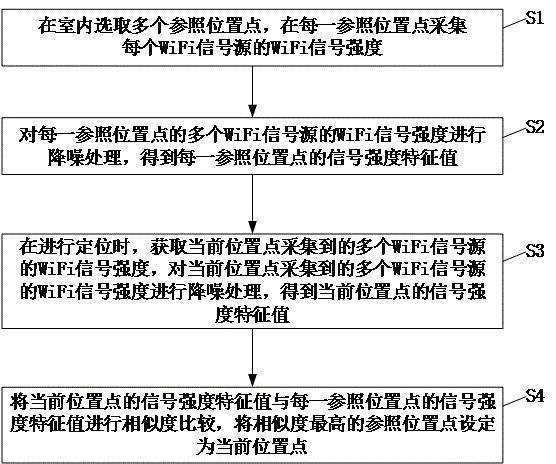

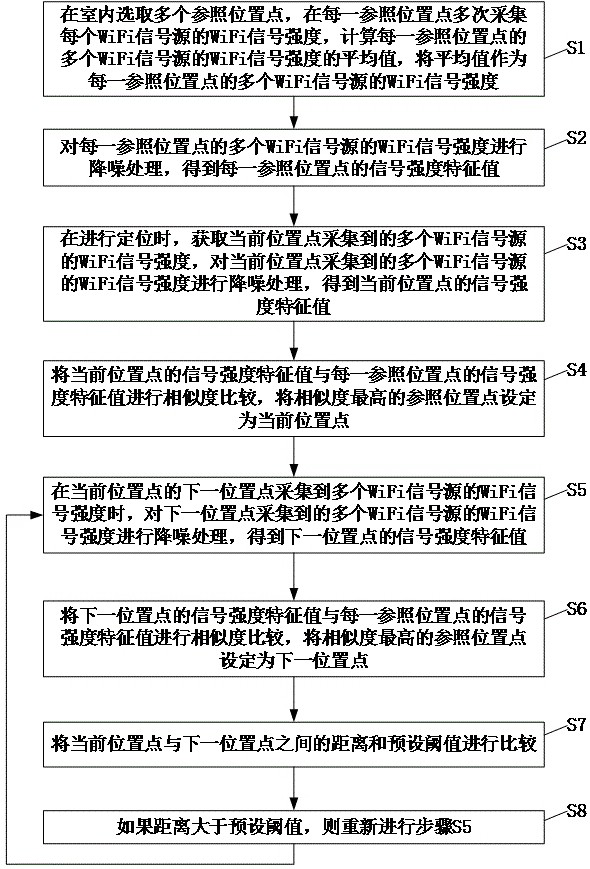

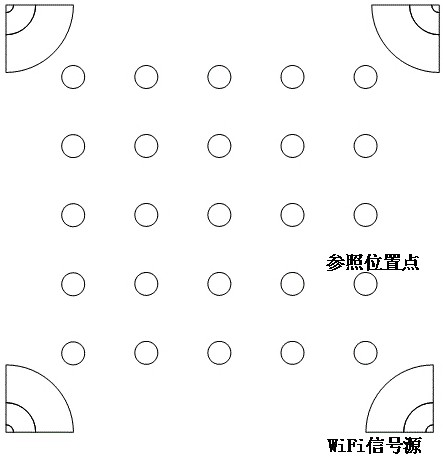

Indoor positioning method based on WiFi

ActiveCN112689237AHigh precisionWide signal rangeParticular environment based servicesLocation information based servicePublic placeEngineering

The invention discloses an indoor positioning method based on WiFi, and the method comprises the steps: selecting a plurality of reference position points indoors, and collecting the WiFi signal intensity of each WiFi signal source at each reference position point; performing noise reduction processing on the WiFi signal intensities of the plurality of WiFi signal sources of each reference position point to obtain a signal intensity characteristic value of each reference position point; when positioning is carried out, acquiring WiFi signal intensities of a plurality of WiFi signal sources collected by a current position point, and carrying out noise reduction processing to obtain a signal intensity characteristic value of the current position point; and performing similarity comparison on the signal intensity characteristic value of the current position point and the signal intensity characteristic value of each reference position point, and setting the reference position point with the highest similarity as the current position point. The problems that in the prior art, positioning interference is large, positioning precision is poor, and equipment needs to be rearranged for public places with different indoor patterns can be solved.

Owner:四川山高聚慧物联网科技有限公司

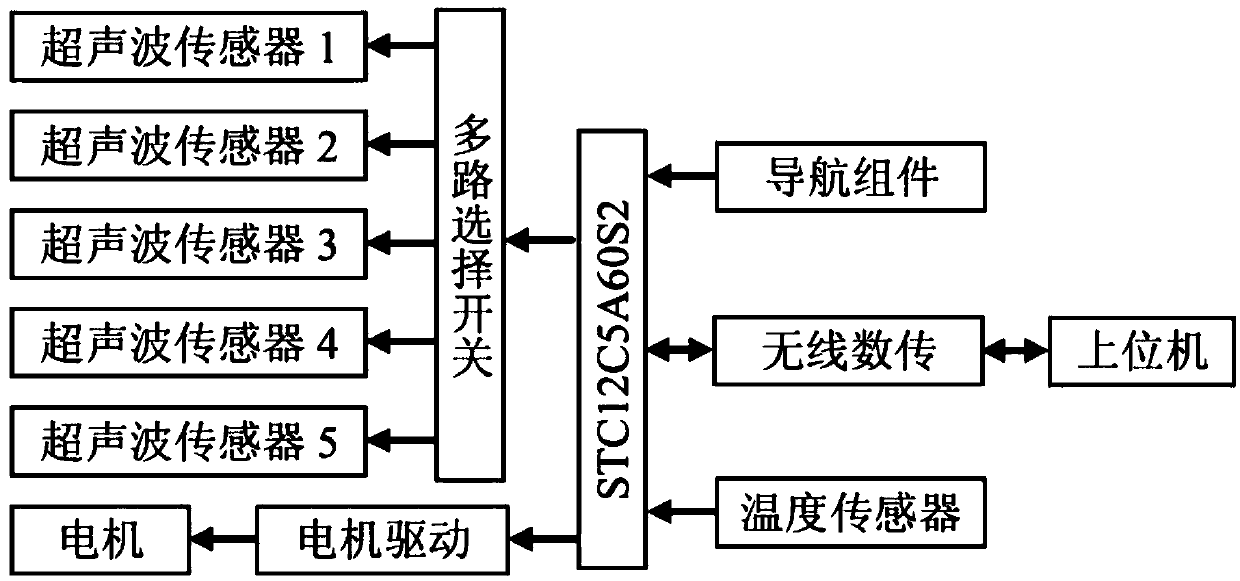

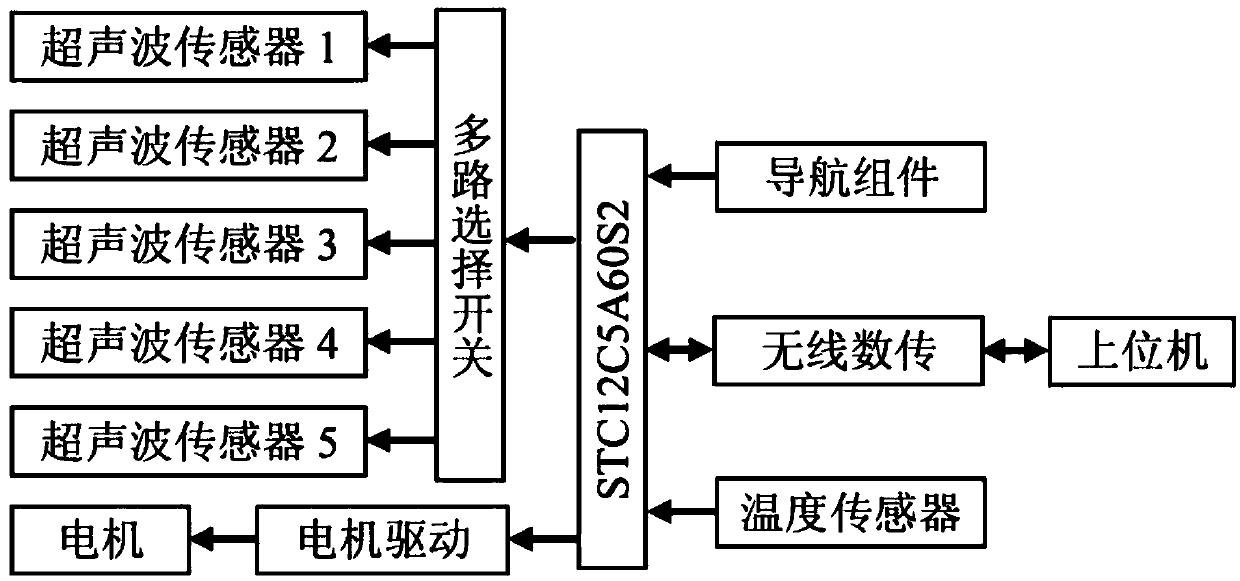

Autonomous mobile intelligent trolley system

InactiveCN109839924AGuaranteed uptimeImprove real-time performancePosition/course control in two dimensionsUltrasonic sensorInformation transmission

The invention relates to an intelligent trolley system, in particular to an autonomous mobile intelligent trolley system. The autonomous mobile intelligent trolley system comprises a single chip microcomputer, a navigation assembly, a wireless data transmission module and a temperature sensor, wherein the single chip microcomputer realizes information transmission with an upper computer by means of the wireless data transmission module, the navigation assembly is connected with the single chip microcomputer, the temperature sensor is connected with an input end of the single chip microcomputer, a control end of the single chip microcomputer is connected with a motor drier, the motor driver is connected with a motor, the control end of the single chip microcomputer is connected with a multi-path selecting switch, and the multi-path selecting switch controls the starting of five ultrasonic sensors. The autonomous mobile intelligent trolley system adopting the technical scheme of the invention can complete route planning and automatic obstacle avoidance through fusing feedback information of multiple modules and multiple sensors after receiving destination position information transmitted by means of the upper computer, and finally achieve functions of autonomous moving, target point temperature acquisition and data transmission of the trolley.

Owner:CHENGDU HONGYU TIMES TECH CO LTD

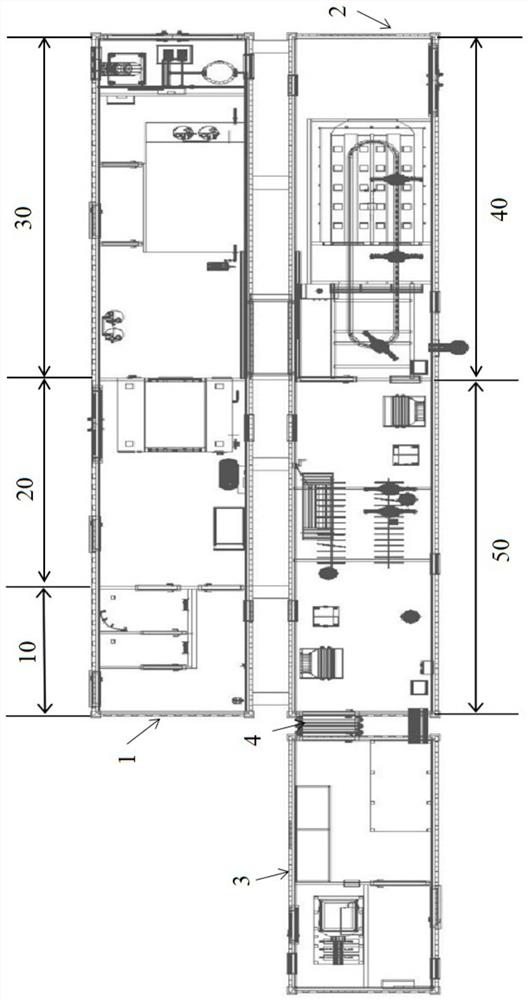

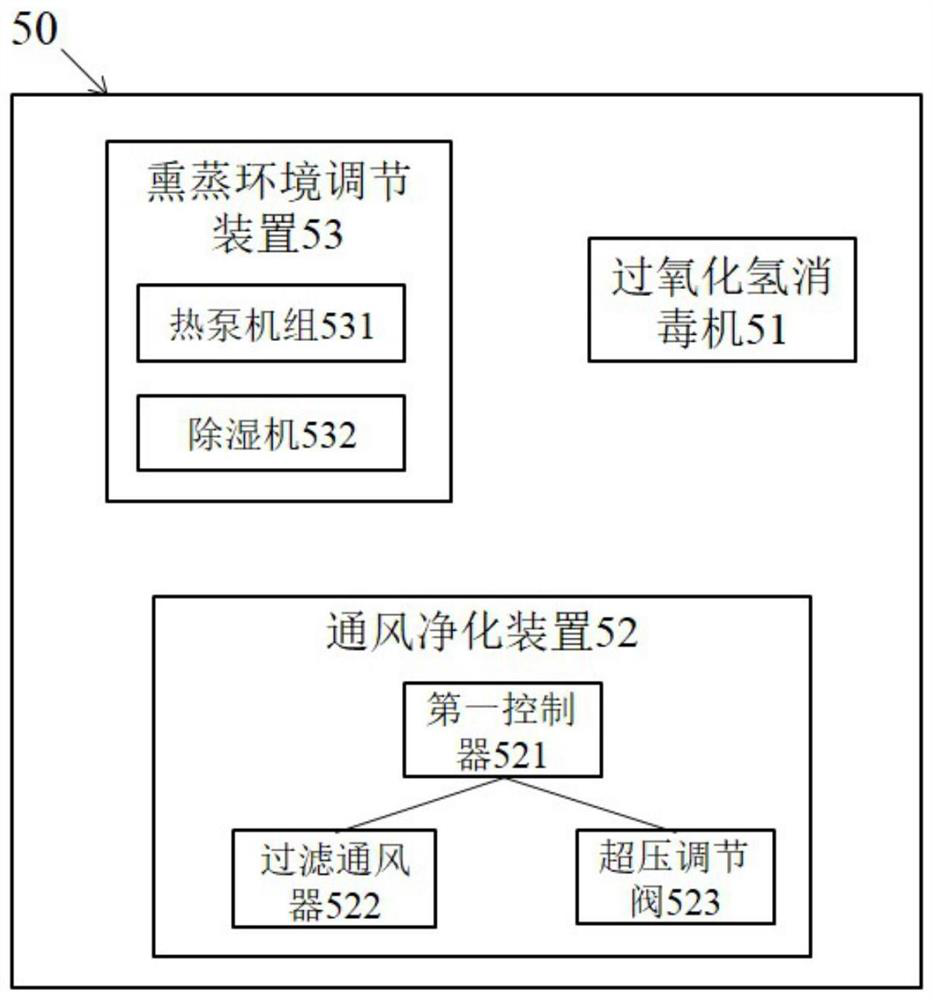

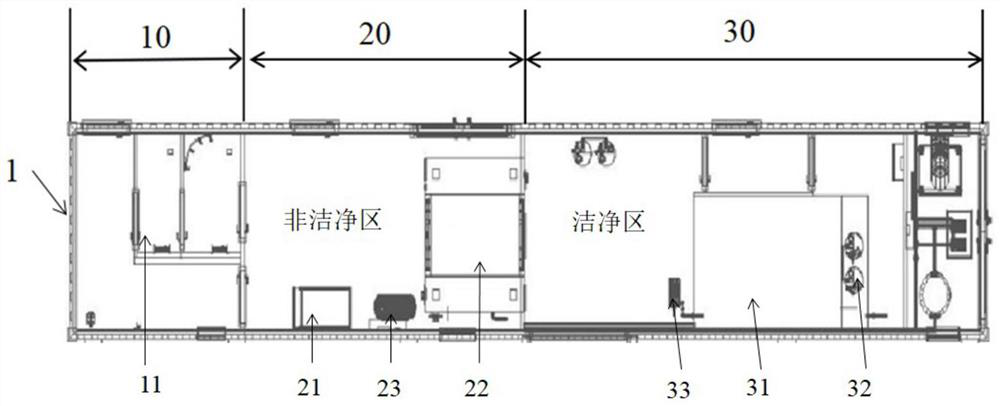

Decontamination system

ActiveCN112190742ARealize repeated decontaminationImprove mobilityLavatory sanitoryDrying chambers/containersSewageSewage treatment

The invention discloses a decontamination system which comprises a first container and a second container which are adjacently arranged, wherein a spray pressing disinfection module, a washing disinfection module and a sewage treatment module are sequentially arranged in the first container, a drying module and a fumigation sterilization module are sequentially arranged in the second container, the spray pressing disinfection module is used for carrying out hydrogen peroxide spray pressing disinfection treatment on reusable medical supplies, the washing disinfection module is used for carryingout washing disinfection treatment on the medical supplies subjected to spray pressing disinfection treatment in a negative pressure environment, the drying module is used for drying the medical supplies subjected to washing disinfection treatment. the fumigation sterilization module is used for carrying out hydrogen peroxide fumigation disinfection treatment on the dried medical supplies, the sewage treatment module is used for treating sewage generated by the spray pressing disinfection module, the washing disinfection module and the fumigation sterilization module. The decontamination system can realize repeated decontamination work of reusable medical supplies.

Owner:北京邦维应急装备有限公司

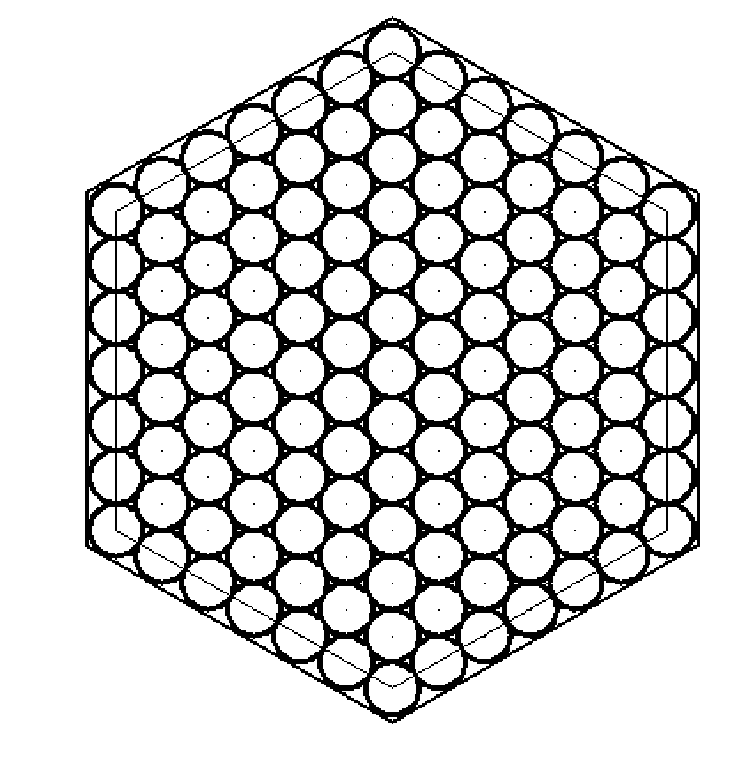

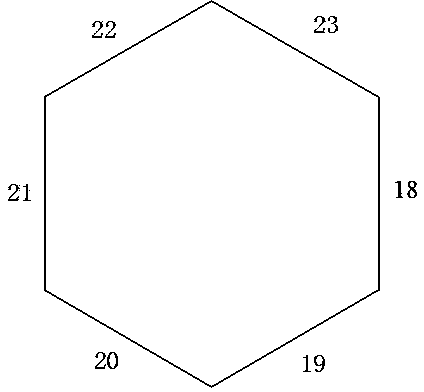

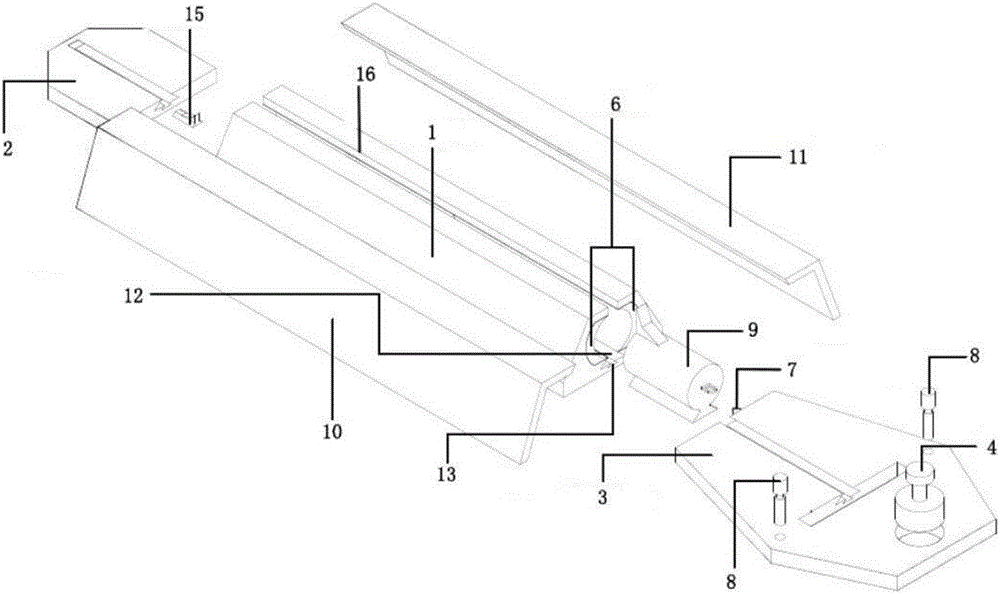

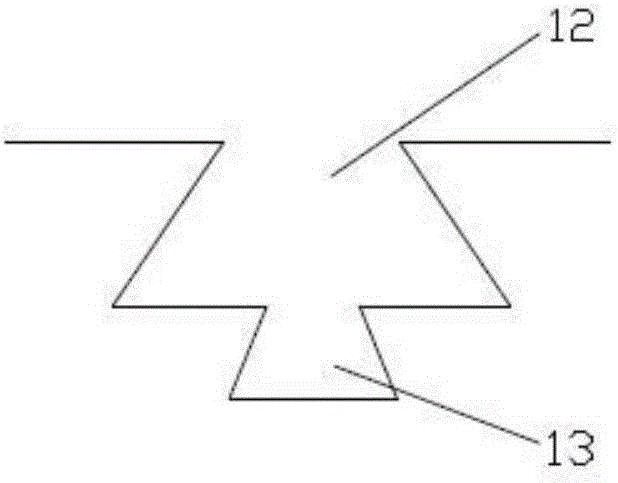

Packaging machine capable of realizing automatical forming and with hexagonal section

The invention discloses a packaging machine capable of realizing automatical forming and with a hexagonal section. A bed saddle (2) is mounted on bed saddle rails (4) of a base (1), a workbench (3) is mounted on workbench rails (6) of the bed saddle (2), a left thin-type air cylinder (8) and a right thin-type air cylinder are mounted on a left retaining plate (10) and a right retaining plate (11) of the workbench (3) respectively, a forming module (17) is composed of a number one submodule (12), a number two submodule (13) and a number three submodule (14), the number one submodule (12) is fixed on the base, the number two submodule (13) is fixed on the workbench (3), and the number three submodule (14) is fixed on the number two submodule (13). The packaging machine capable of realizing automatical forming and with the hexagonal section is accurate in counting and simple and convenient to operate, manual forming errors are eliminated, labor intensity is reduced, and resource consumption is lowered.

Owner:HUAIAN COLLEGE OF INFORMATION TECH

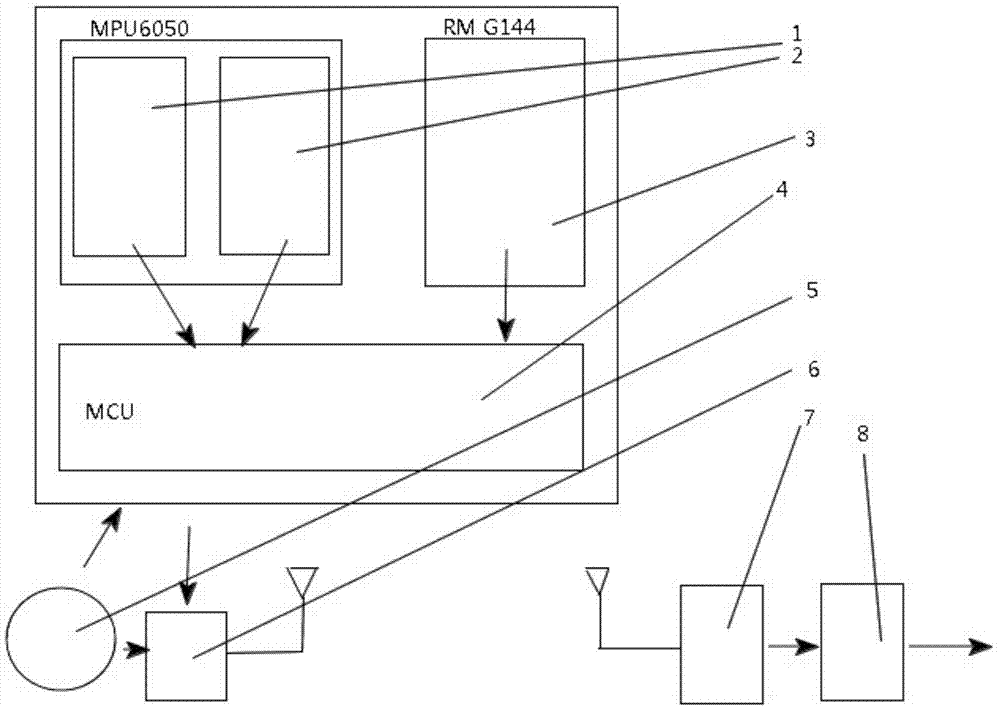

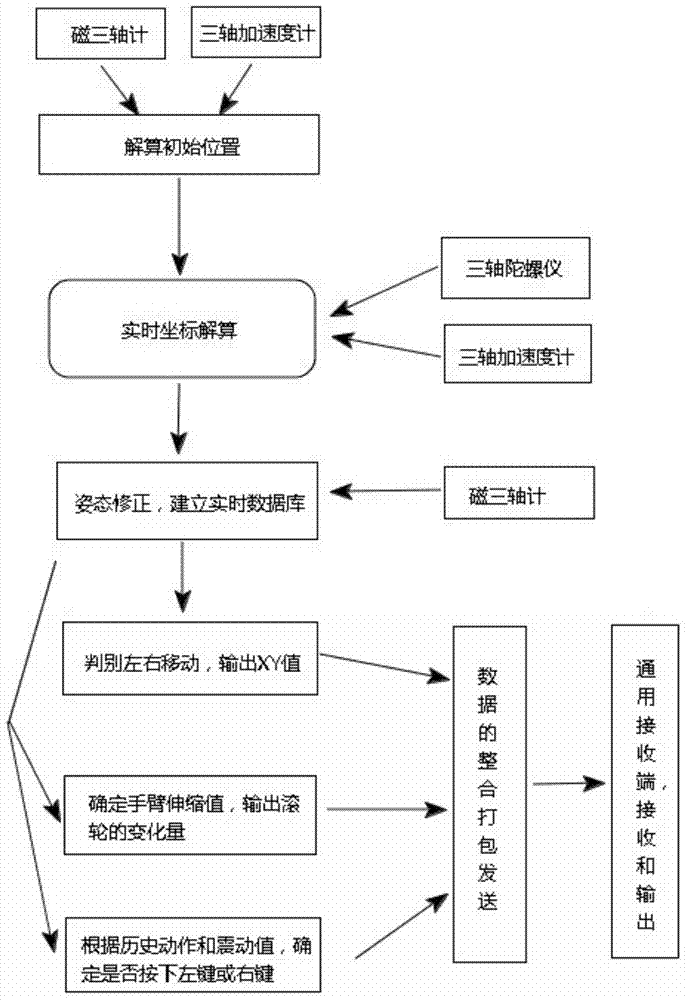

Multi-purpose mouse capable of locating through spatial absolute position

InactiveCN104516528AImprove recognition accuracyImprove anti-interference abilityInput/output processes for data processingGyroscopeComputer module

The invention provides a multi-purpose mouse capable of locating through a spatial absolute position. A multi-purpose mouse body comprises the six parts; sensing chips MPU6050 (1) and (2) are respectively composed of a three-axis acceleration sensor and a three-axis gyro; a three-axis magnetic field meter RMG144 (3) is provided; the two sensing chips send the sensed acceleration and acceleration and magnetic field strength of each axis to a a main processor (4) through an I2C bus; the (4) performs initial calculation for the posture to determine an absolute spatial coordinate system, calculates the posture and distinguishes an action signal and finally outputs the absolute position of the current space, a button to be controlled and the function to a wireless emitting module (6); a power module (5) supplies power to the whole system; a wireless receiving module (7) of the receiving part is used for receiving and decoding; a interface module (8) processes data into the general variable of the mouse in a USB device and then sends to the system.

Owner:NANJING ZHUANCHUANG INTPROP SERVICES

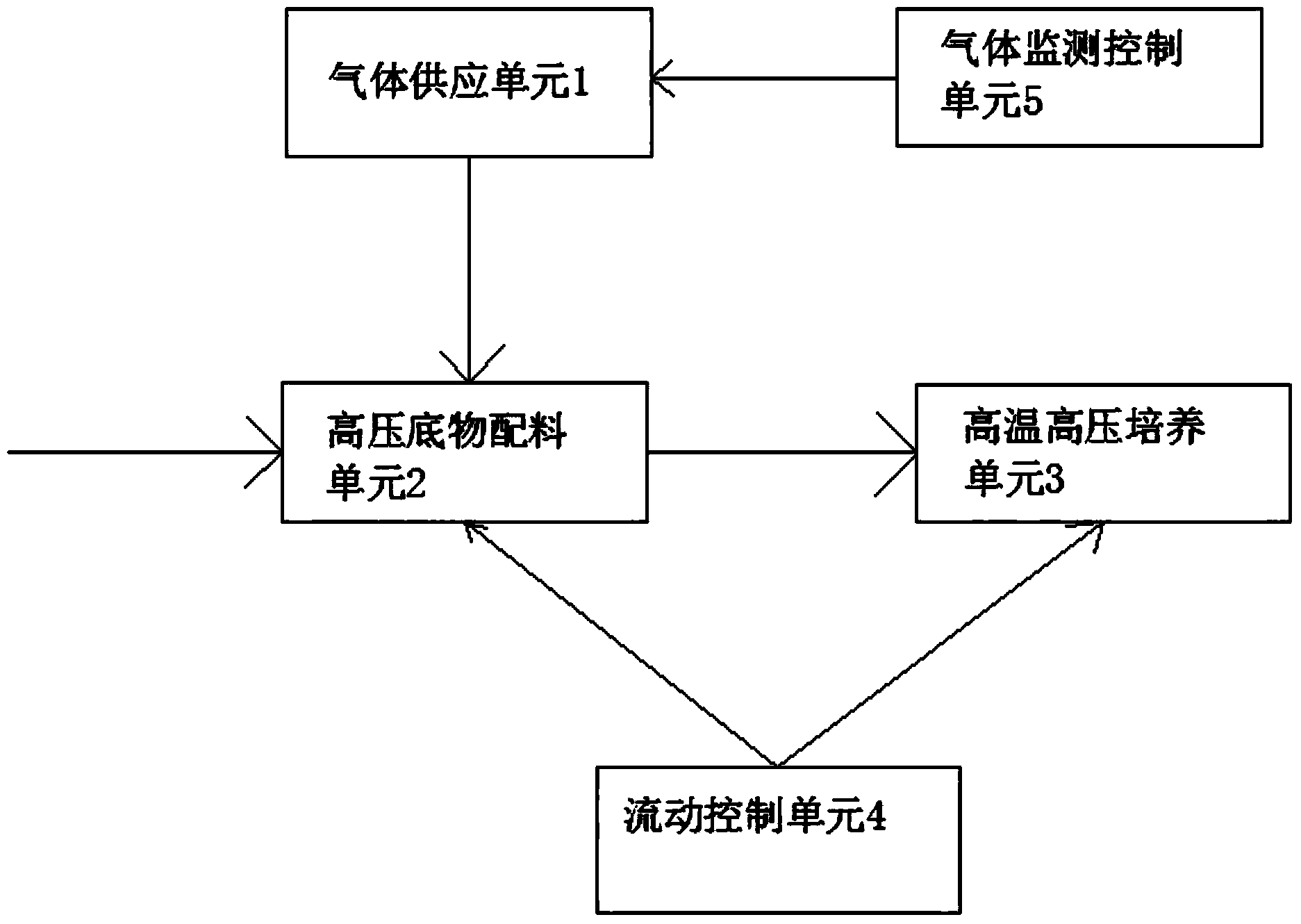

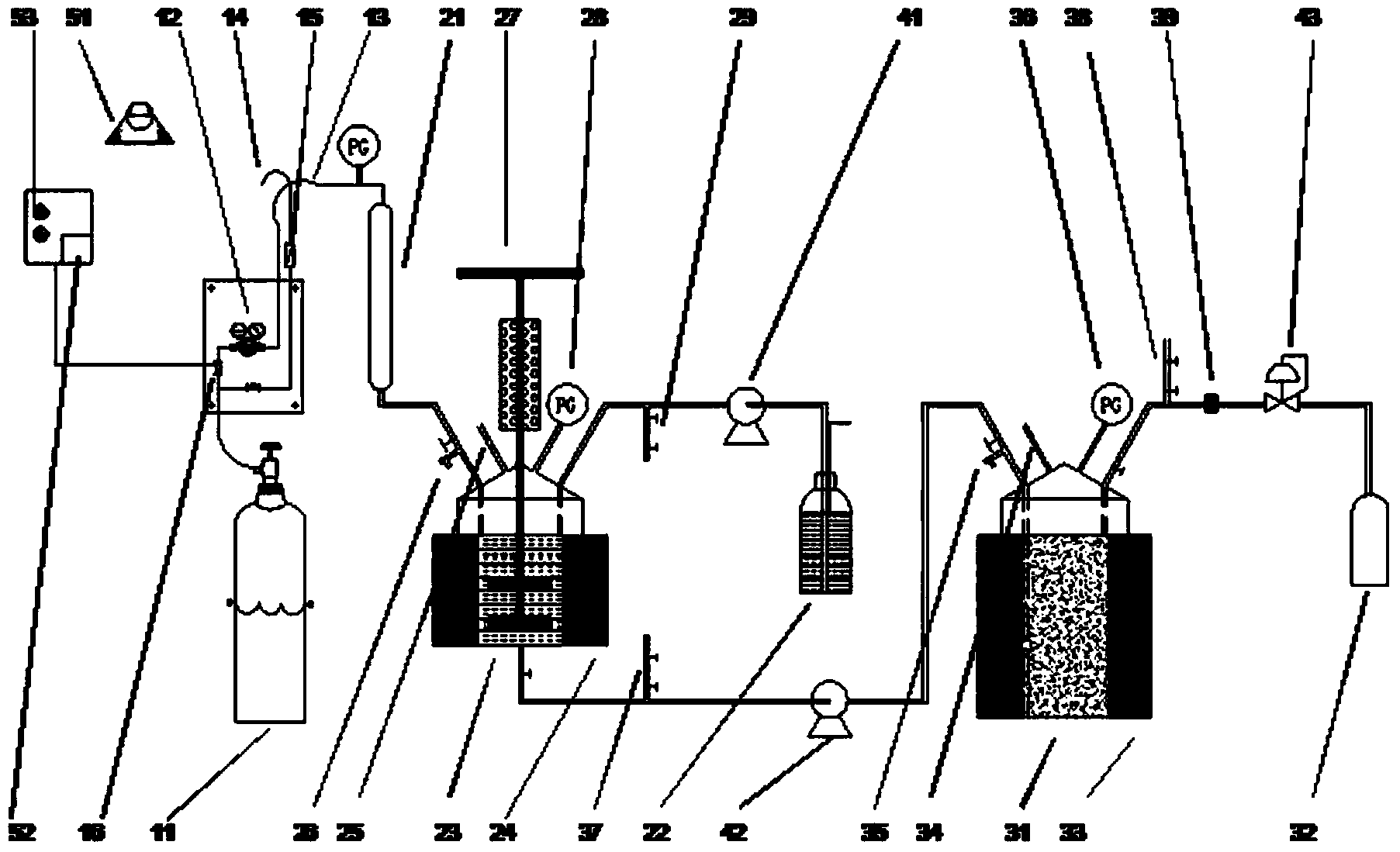

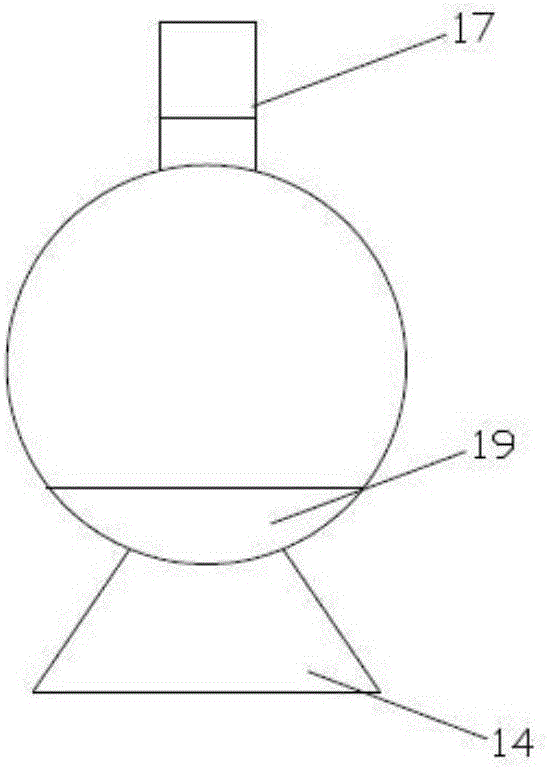

Deep sea thermal solution simulation and high-temperature high-pressure microorganism culture system

ActiveCN103540522BSimple structureTechnically reasonableBioreactor/fermenter combinationsBiological substance pretreatmentsHigh concentrationThermal solution

The invention relates to the technical field of environmental simulation and microorganism culture, and in particular relates to a deep sea thermal solution simulation and high-temperature high-pressure microorganism culture system comprising a gas and liquid transmission pipeline, and further comprising a high-pressure substrate batching unit for uniformly mixing high-pressure gas and high-pressure seawater to obtain a high-pressure seawater culture medium dissolved with high-concentration gas, a high-temperature high-pressure culture unit for acquiring the high-pressure seawater culture medium from the high-pressure substrate batching unit to breed microorganism, a gas supply unit for providing high-pressure gas for the high-pressure substrate batching unit and the high-temperature high-pressure culture unit, a flow control unit for controlling pressure in the high-pressure substrate batching unit and the high-temperature high-pressure culture unit as well as a flow velocity in a continuous culture process, and a gas monitoring control unit for detecting concentration of combustible gas in an environment, judging leakage of the combustible gas in the high-pressure substrate batching unit and the high-temperature high-pressure culture unit, and alarming in real time or automatically cutting off gas supply of the gas supply unit depending on a judgment result.

Owner:SHANGHAI JIAO TONG UNIV

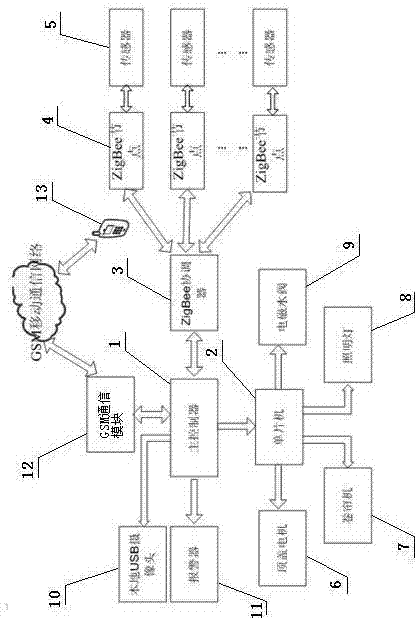

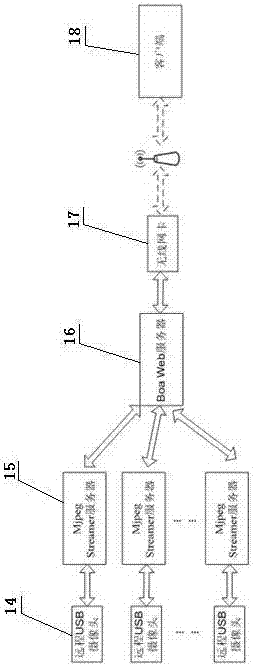

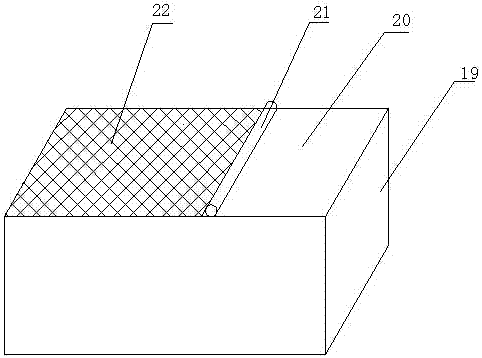

A kind of intelligent control system and method of internet of things for greenhouse

InactiveCN104181887BMeet basic management needsSave management time investmentProgramme total factory controlMicrocontrollerVideo monitoring

The present invention provides a kind of intelligent control system of Internet of things for greenhouse, comprises indoor environment monitoring control part and remote video monitoring part; Described indoor environment monitoring control part comprises ZigBee coordinator, master controller and single-chip microcomputer connected in sequence, so The main controller is connected with a local USB camera and an alarm, the single-chip microcomputer is connected with a shutter machine, an electromagnetic water valve, a top cover motor and a light, and the ZigBee coordinator is connected with several ZigBee nodes, and each ZigBee node is connected with several ZigBee nodes. Measure the sensor of environmental parameter; Described long-distance video monitoring part comprises the long-distance USB camera, Mjpeg Streamer server and Boa web server connected in sequence, and described Boa web server carries out network connection with client through Internet. The control system of the invention has a high degree of integration and automation, and can realize intelligent control and management of multiple parameters.

Owner:深圳市盛事金服科技有限公司

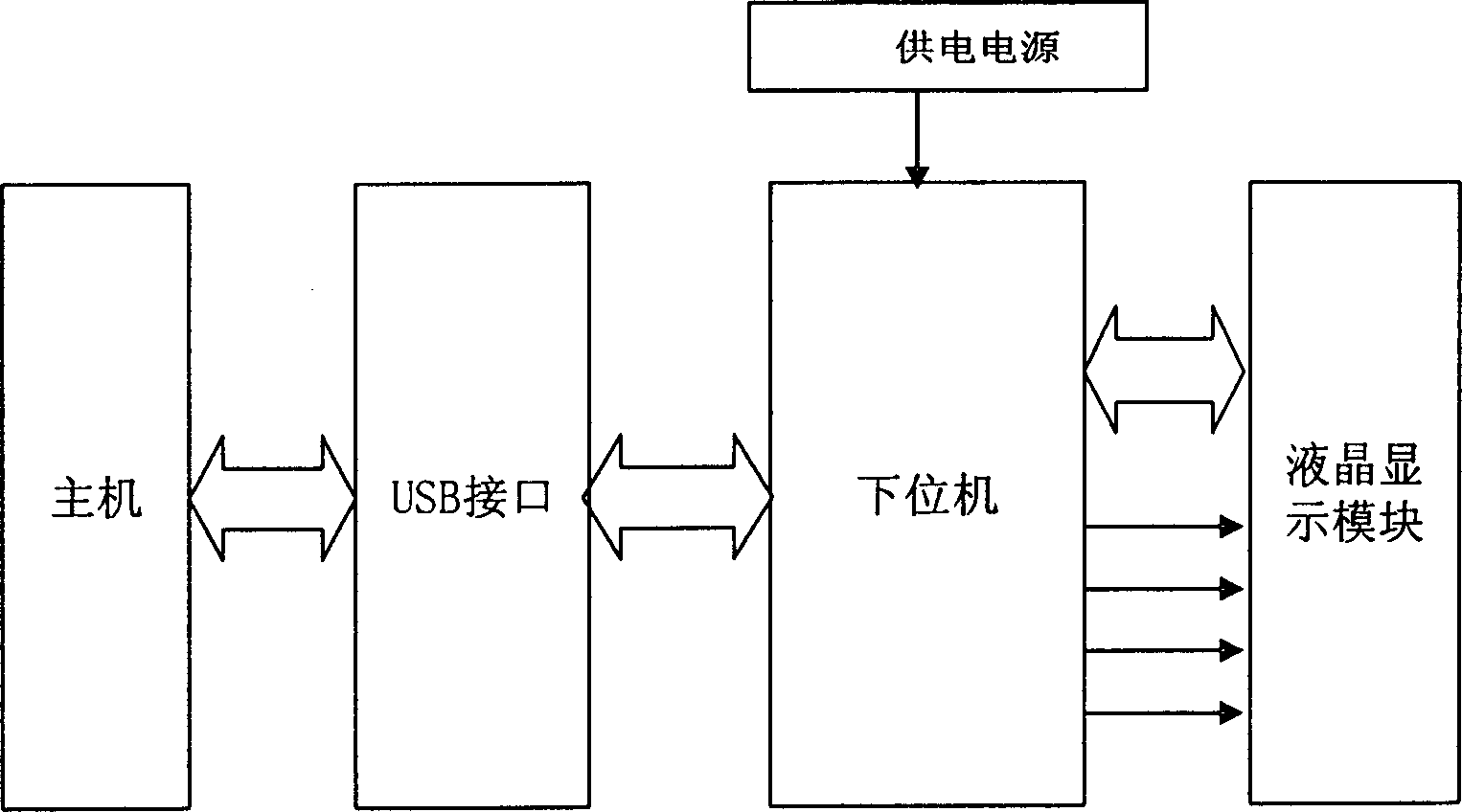

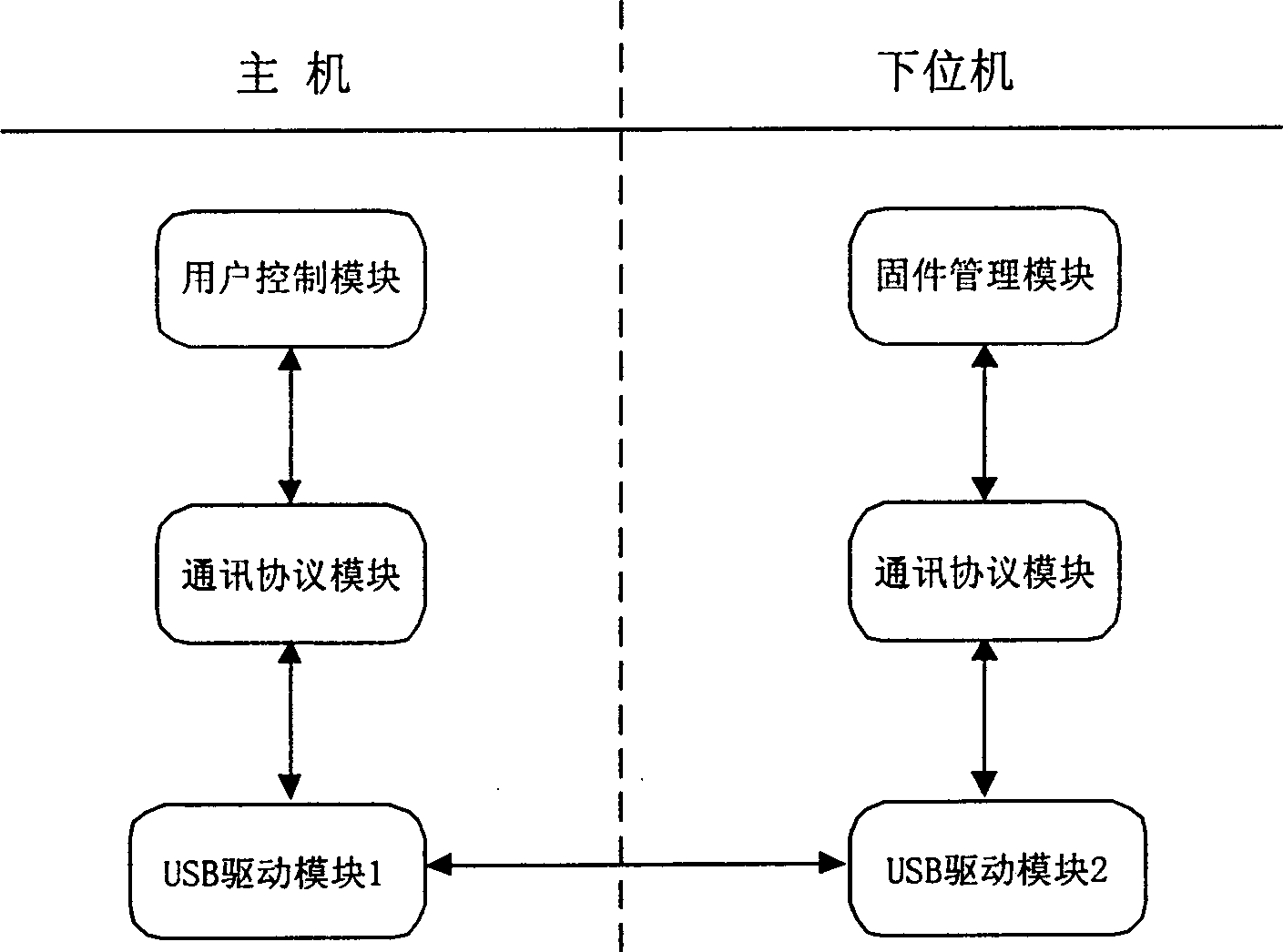

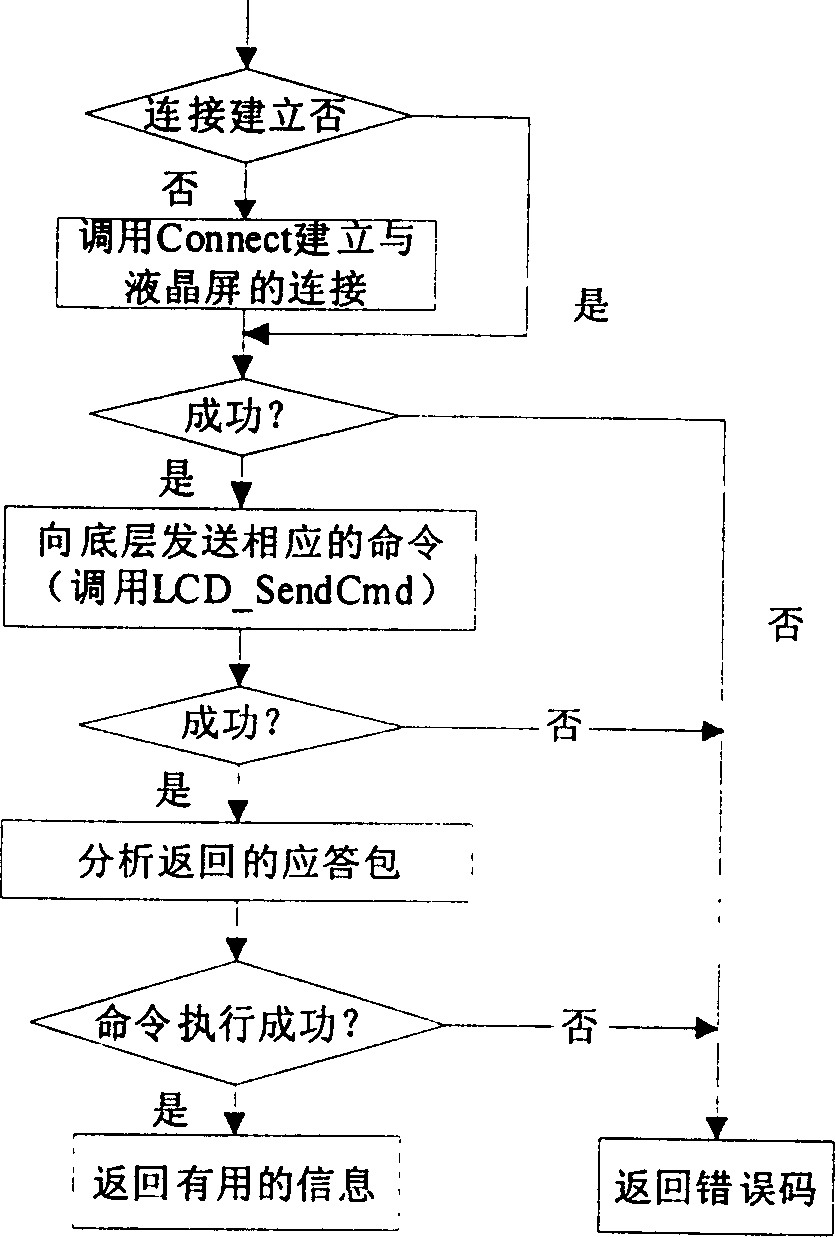

Micro computer auciliary display device and information display method

InactiveCN1277177CImprove interactivityImprove usabilityProgram control using stored programsMemory systemsMicrocomputerRelevant information

The auxiliary microcomputer display device includes host computer, lower computer capable of performing USB communication with the host computer, power source and LCD module. The host computer is used to provide the lower computer with content to be displayed according to application program; the lower computer connected via USB interface to the host computer is used to receive the system information, complete analysis and processing and output to the LCD module; and the LCD module is used to receive data from the lower computer and display image information. The present invention makes it possible for the user to obtain relevant information while operating computer and o use microcomputer interactively and easily. The present invention has the advantages of simple layering, high universality and high updating possibility.

Owner:LENOVO (BEIJING) LTD

Packaging machine for automatic forming of hexagonal section

The invention discloses a packaging machine capable of realizing automatical forming and with a hexagonal section. A bed saddle (2) is mounted on bed saddle rails (4) of a base (1), a workbench (3) is mounted on workbench rails (6) of the bed saddle (2), a left thin-type air cylinder (8) and a right thin-type air cylinder are mounted on a left retaining plate (10) and a right retaining plate (11) of the workbench (3) respectively, a forming module (17) is composed of a number one submodule (12), a number two submodule (13) and a number three submodule (14), the number one submodule (12) is fixed on the base, the number two submodule (13) is fixed on the workbench (3), and the number three submodule (14) is fixed on the number two submodule (13). The packaging machine capable of realizing automatical forming and with the hexagonal section is accurate in counting and simple and convenient to operate, manual forming errors are eliminated, labor intensity is reduced, and resource consumption is lowered.

Owner:HUAIAN COLLEGE OF INFORMATION TECH

Stereo vision-based intelligent detachable mobile robot system and control method

ActiveCN108646759BMaximize UtilizationHighly integratedPosition/course control in two dimensionsInformation transmissionComputer graphics (images)

The invention discloses an intelligent detachable mobile robot system and control method based on stereo vision. By combining stereo vision, an interactive system and a motion control system, the mobile robot can easily and quickly understand the environment in an unfamiliar environment. Various functions are realized on the basis of machine-computer interaction, and various tasks are completed with the assistance of motion control. Compared with traditional robots, the combination of stereo vision and interactive systems can make up for the lack of quality and quantity of information acquisition and the one-way problem of information transmission, and has the advantages of human-computer interaction and environmental understanding. The detachability of the present invention solves the problem that the integrated robot can only work in one background and realize one kind of intelligent operation. The utility model has the advantages of convenient use, low cost and easy popularization.

Owner:WUHAN UNIV OF SCI & TECH

Novel quadrupole magnetic force acceleration system

The present invention relates to a novel quadrupole magnetic force acceleration system. The system comprises a main framework, an object support, an elastic body, a permanent magnet, a track and a pedestal. The section of the main framework is trapezoid, the inner side of the framework is provided with a tile-shaped permanent magnet, the inner cavity enclosed by the tile-shaped permanent magnet forms a cylindrical pathway in the main frame, and the elastic body can do one-dimensional motion in the cylindrical pathway; the object support comprises a left object support and a right object support, the upper end surfaces of the object support is leveled with the upper end surface of the main framework and are fixed at two sides of the main framework; the front end of the main framework is provided with a front-end substrate, the back end of the main framework is provided with a back-end substrate, and the pathway is arranged in the front-end substrate, the main framework and the back-end substrate in the section mode; and the elastic body is connected with the transmission device through a connection piece, the middle portion of the upper end surface of the main framework has a reserved slit, and the upper end of the elastic body has corresponding projections. The novel quadrupole magnetic force acceleration system facing students and scientific research institutions does not need the driving of the pulse power supply, takes a permanent magnet as an energy storage unit and employs the machinery energy charge mode so as to greatly improve the energy conversion rate.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

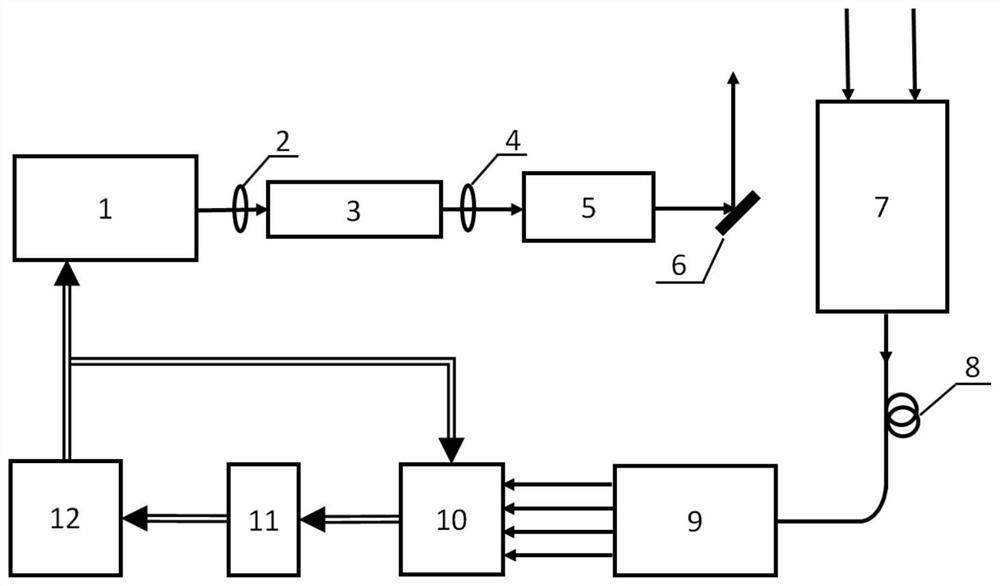

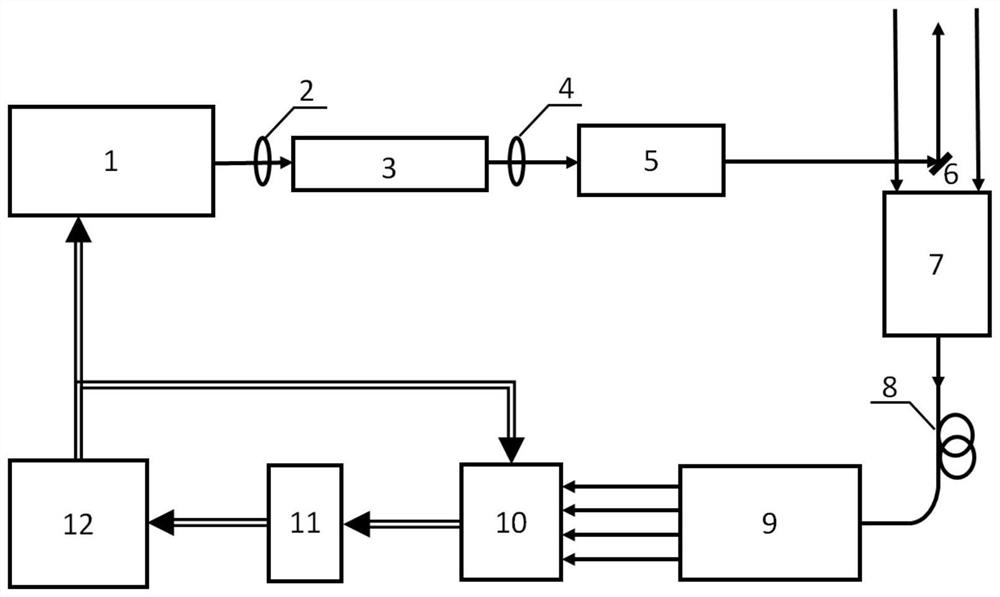

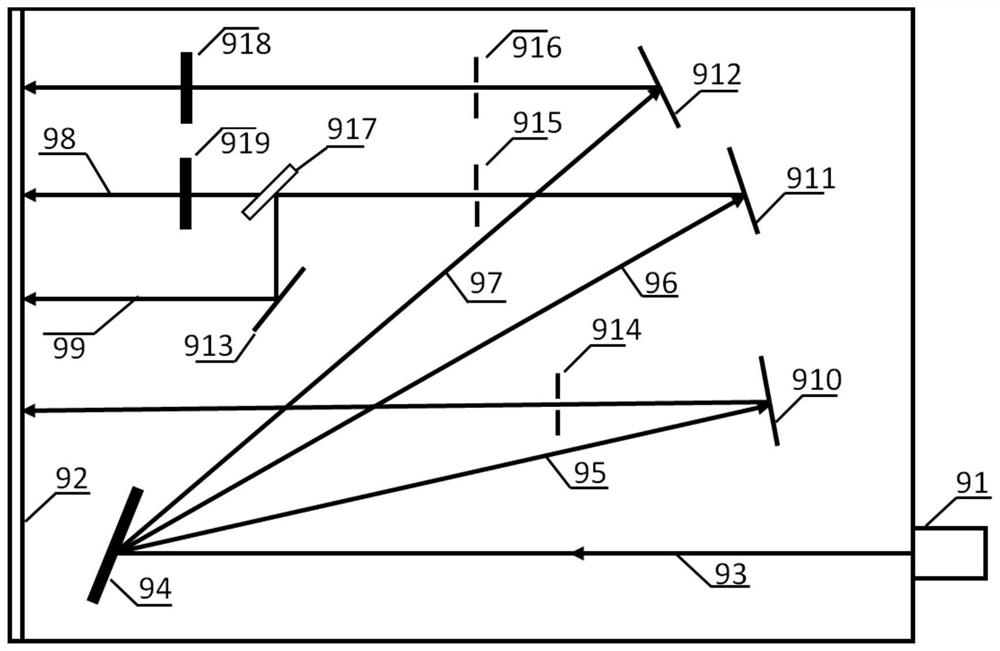

A multi-wavelength ozone lidar based on single-photon ccd

ActiveCN108919301BLarge room for upgradeLarge vertical height upgrade spaceElectromagnetic wave reradiationICT adaptationBeam expanderPhoton detection

The invention discloses a multi-wavelength ozone laser radar based on a single-photon CCD, comprising: a Nd-YAG quadruple frequency laser, an optical lens, a Raman tube, a beam expander, a plane mirror, an optical receiving module, a spectrometer, a detection module, Data acquisition and synchronization control unit. The present invention is based on a single Raman tube stimulated Raman to generate multi-wavelength lasers. By using the echo signals of different wavelength pairs for differential inversion, the ozone concentration can be measured with high precision within a large vertical height range. The use of the Mann tube not only simplifies the device, but also reduces the difference in geometrical factors of different wavelength lasers and improves the measurement accuracy of the device. In addition, the use of single-photon CCD not only simplifies the composition of the detection part, reduces the measurement error caused by the difference of the detector, makes the lidar device have a large upgrade space, but also benefits from the high sensitivity of single-photon detection , increasing the maximum measurement height of the device.

Owner:山东国耀量子雷达科技有限公司

A multifunctional diaper robot packing machine

The invention discloses a multifunctional paper diaper robot box filling machine. The robot box filling machine comprises a suction type box filling part and a clamping type box filling part, whereinthe suction type box filling part comprises a four-section feeding part, a six-axis box filling robot, a side pushing mechanism, a box opening mechanism, a sucker gripper, a suction platform and a roller conveying line; the clamping type box filling part comprises a four-section feeding part, a six-axis box filling robot, an arrangement mechanism, a clamping platform, a side pushing mechanism, a box opening mechanism, a clamping gripper and a roller conveying line. The multifunctional paper diaper robot box filling machine has the advantages as follows: the multifunctional paper diaper robot box filling machine has double functions, the suction type box filling form and the clamping type box filling form are combined, the application range of the box filling machine is greatly enlarged, and the production cost is reduced.

Owner:NANTONG UNIVERSAL MACHINERY

Intelligent cooking robot and cooking method

InactiveCN101574231BRealize intelligent controlConducive to uniform standardsCooking vesselsProgramme control in sequence/logic controllersProcess engineeringCooking methods

The invention relates to an intelligent cooking robot and a cooking method, aiming at overcoming the defect that the market of household appliances develops slowly at present. The intelligent cooking robot comprises a cooking device (1) which is provided with a pressure sensor base (2) and connected with a conveying passage (3) and an exhaust passage (4), wherein the conveying passage is respectively connected with a water storage container (5) and a rice storage container (6) and provided with a valve (7); and the valve, the cooking device and the pressure sensor base are respectively connected with a main control panel (8). The intelligent cooking robot is an intelligent cooking device.

Owner:HARBIN UNIV OF SCI & TECH

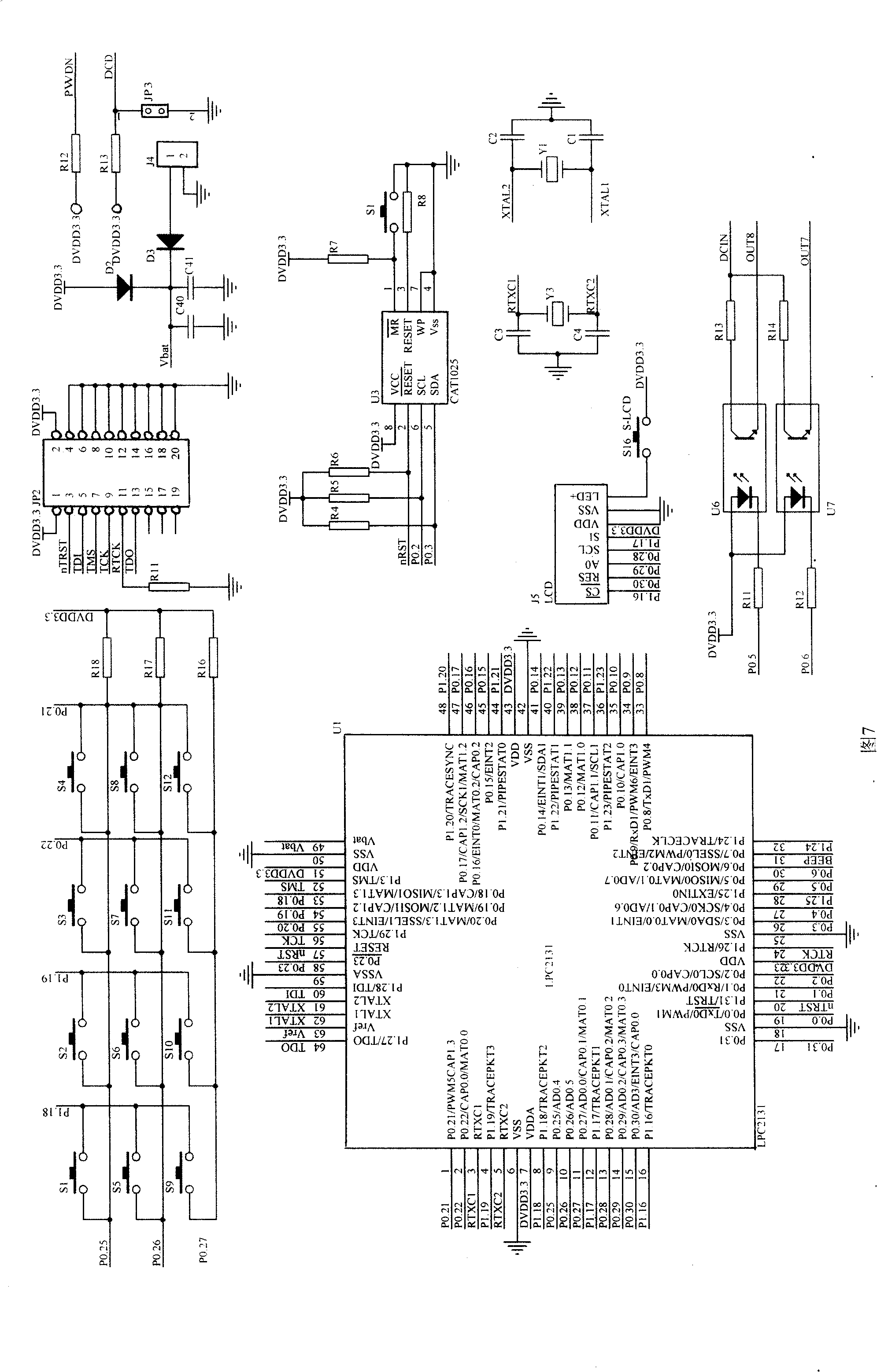

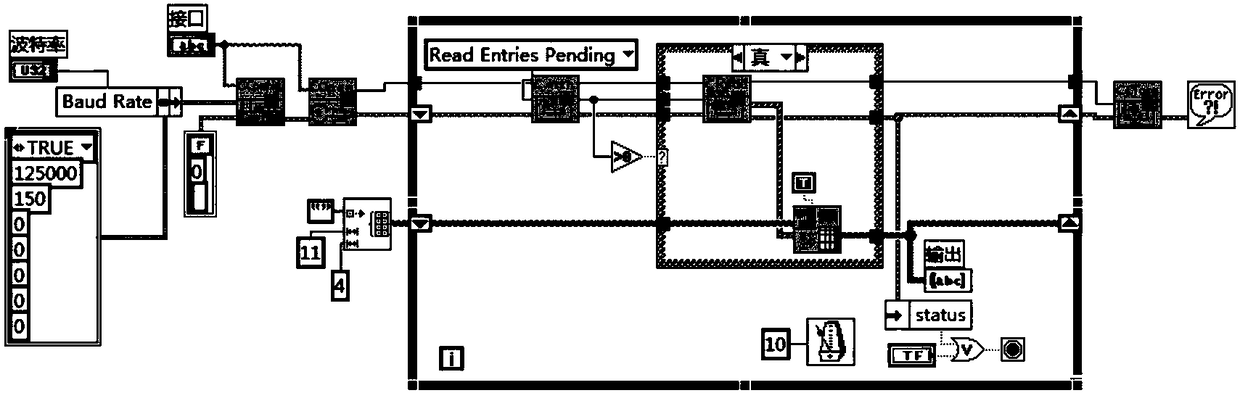

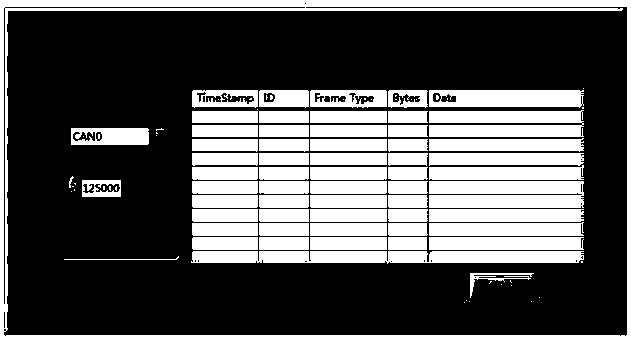

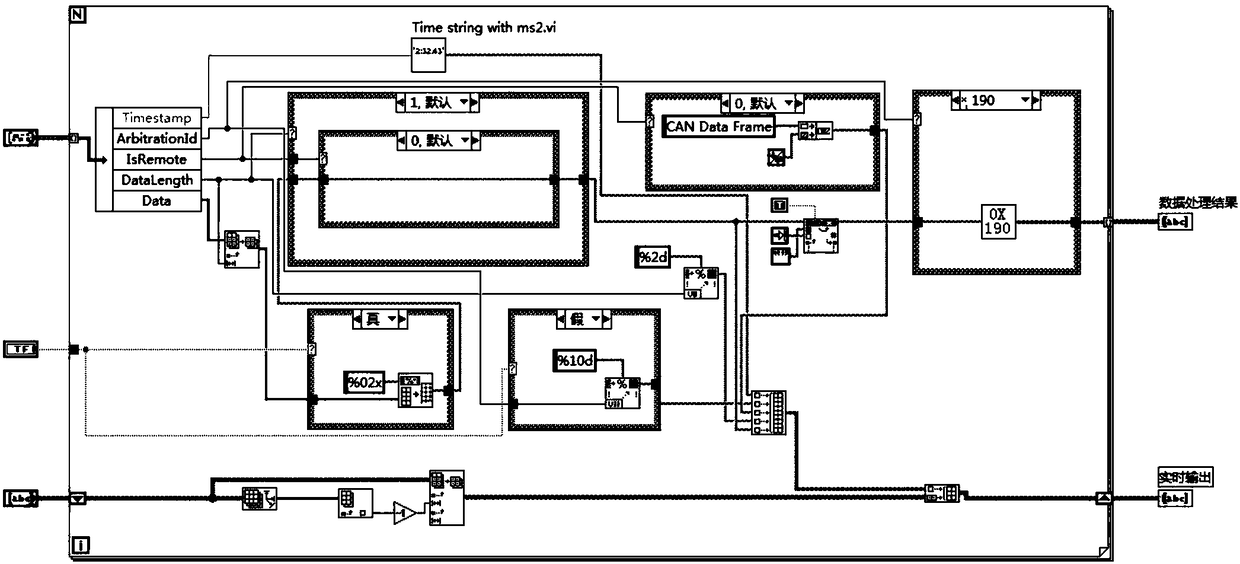

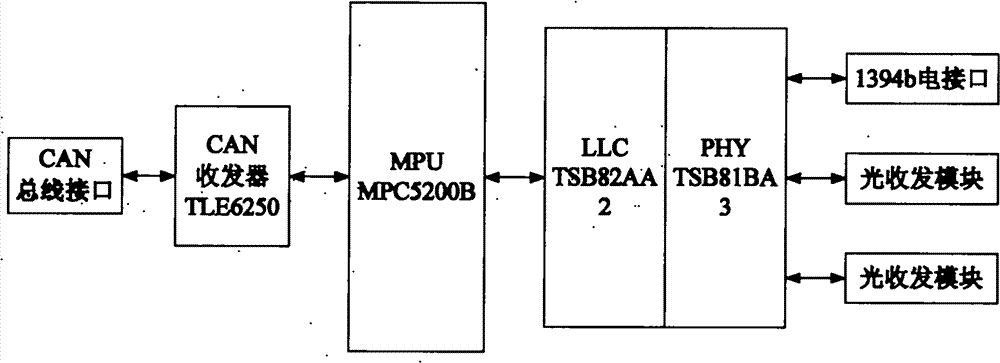

A realization method of vehicle communication system based on Formula Student racing car

ActiveCN105681435BMeet the use requirementsMeet design goalsTransmissionCommunications systemComputer module

The invention discloses a realization method of a full car communication system based on a formula student race car. The method comprises following steps of determining data needing to be collected for an all-electric race car of this time; determining modules using CAN bus communication according to demands; setting CAN bus priories, wherein a protocol identity ID is set for each module; setting a CAN bus protocol, wherein the bus protocol is set according to using demands; developing and designing CAN communication programs; and testing and analyzing the CAN bus communication.

Owner:ZHEJIANG UNIV OF TECH

A vehicle speed guidance system and method for reducing parking at signalized intersections

ActiveCN108682168BReduce real-time speed guideReduce parking timeArrangements for variable traffic instructionsTraffic signalSimulation

The invention provides a speed guiding system and method that reduces signal intersection pausing, and belongs to the traffic management and control technical field; the speed guiding system comprisesthe following parts: a traffic signal control subsystem used for controlling a signal lamp phase in real time according to real time traffic conditions, receiving traffic signal phase request information from a speed guiding device, and returning the corresponding traffic signal phase information to the speed guiding device; the speed guiding device arranged on a vehicle and used for communicating the traffic signal control subsystem in real time, sending the traffic signal phase information request to the traffic control subsystem with certain frequency via communication, receiving feedbackinformation from the traffic signal control subsystem, and providing a suggestion speed value for the vehicle according to the feedback information. The speed guiding system and method can solve the problems that an existing method cannot control to reduce the signal intersection pausing problem; the speed guiding system and method can be applied to intersection speed guiding.

Owner:HARBIN INST OF TECH

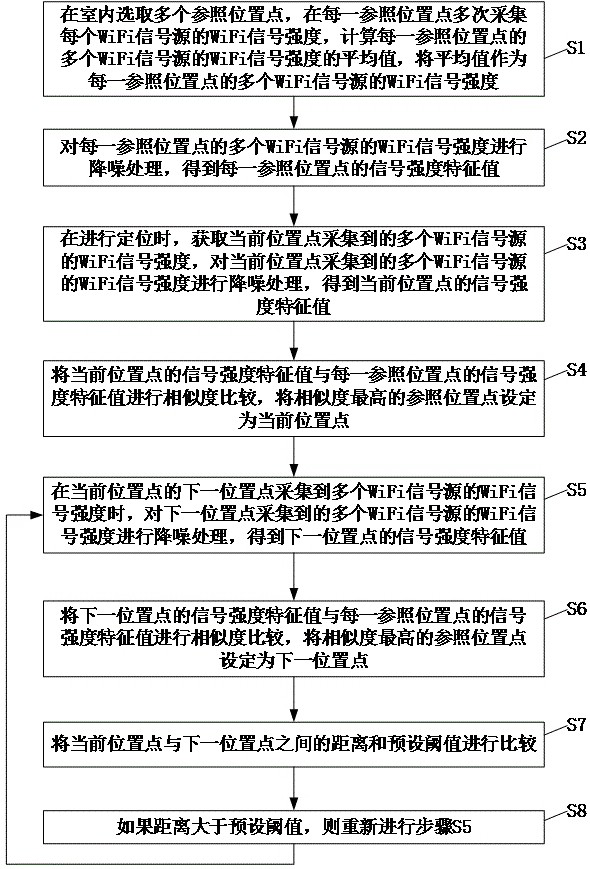

A WiFi-based indoor positioning method

ActiveCN112689237BHigh precisionWide signal rangeParticular environment based servicesLocation information based servicePublic placeEngineering

The invention discloses a WiFi-based indoor positioning method, comprising: selecting a plurality of reference position points indoors, collecting the WiFi signal strength of each WiFi signal source at each reference position point; The WiFi signal strength of the WiFi signal source is subjected to noise reduction processing to obtain the signal strength characteristic value of each reference position point; when positioning, obtain the WiFi signal strength of multiple WiFi signal sources collected at the current position point, and perform noise reduction Process to obtain the signal strength characteristic value of the current position point; compare the signal strength characteristic value of the current position point with the signal strength characteristic value of each reference position point, and set the reference position point with the highest similarity as the current position point. The invention can solve the problems in the prior art that the positioning interference is large, the positioning accuracy is poor, and the equipment needs to be rearranged for public places with different indoor layouts.

Owner:四川山高聚慧物联网科技有限公司

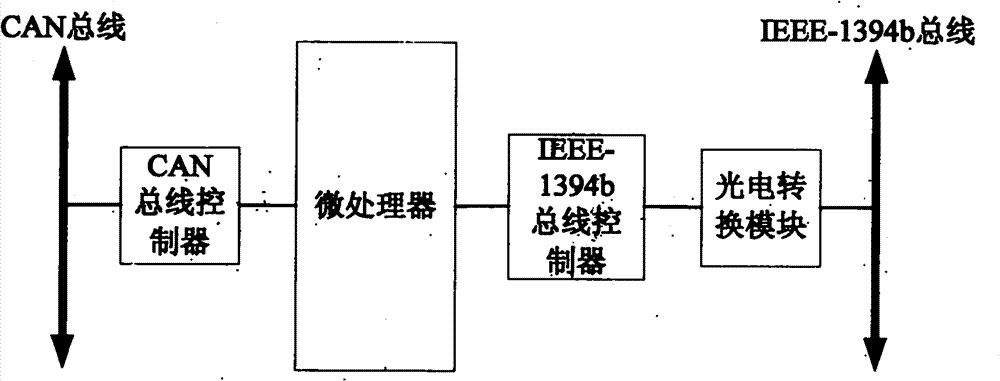

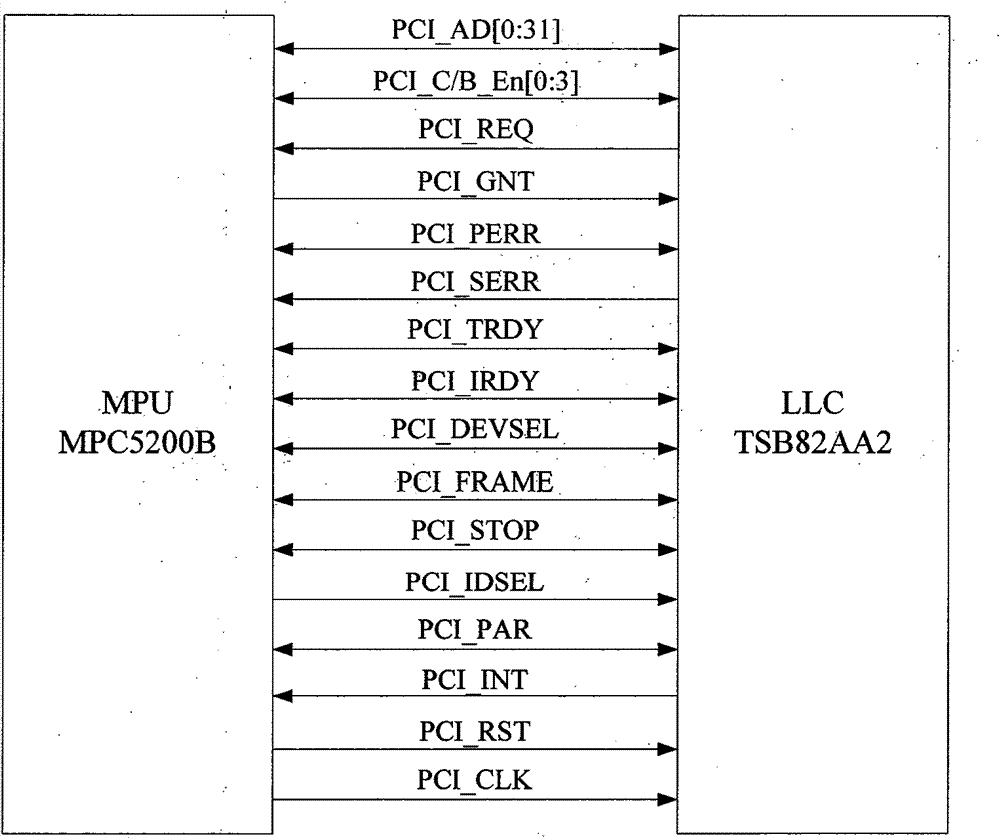

IEEE-1394b bus and CAN bus protocol converter based on microprocessor

InactiveCN101795262BRealize communication interconnectionFast transmissionBus networksPhotoelectric conversionInterconnection

The invention provides an IEEE-1394b bus and CAN bus protocol converter based on microprocessor, belonging to the field bus technical field. The protocol converter comprises a CAN bus interface connected with CAN bus and an IEEE-1394b bus interface connected with IEEE-1394b bus, a microprocessor is respectively connected with the CAN bus interface and the IEEE-1394b bus interface by a CAN bus controller and an IEEE-1394b bus controller, and the protocol converter also comprises a photoelectric conversion module and a periphery circuit module for realizing IEEE-1394b fiber connection. The microprocessor is embedded with software for successful conversion of protocol, thus realizing butt joint of data of the two networks. The invention adopts the microprocessor to control the interconverionof CAN bus protocol and IEEE-1394b bus protocol, solves the communication interconnection problem of CAN bus interface product and IEEE-1394b bus interface product and has the characteristics of fasttransmission speed, good timeliness, large upgrading space and wide application field.

Owner:BEIHANG UNIV

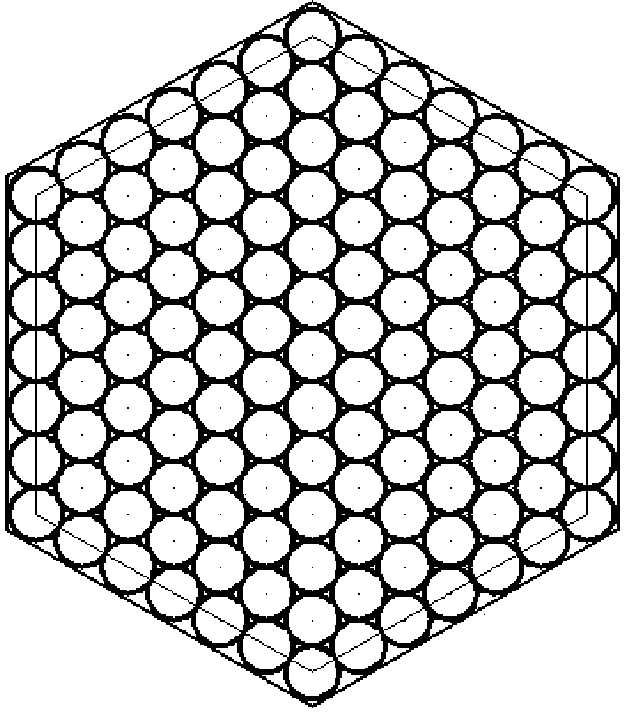

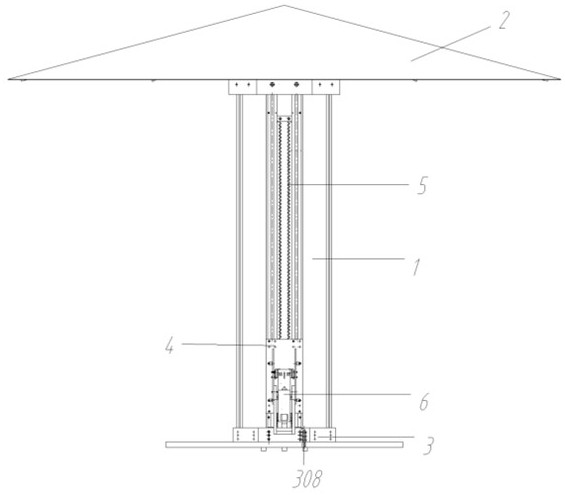

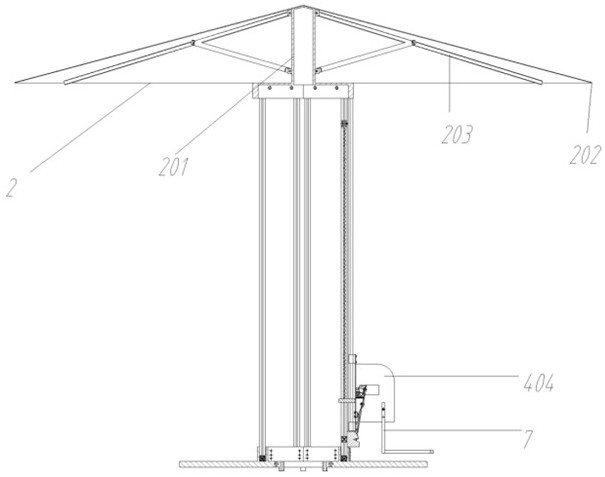

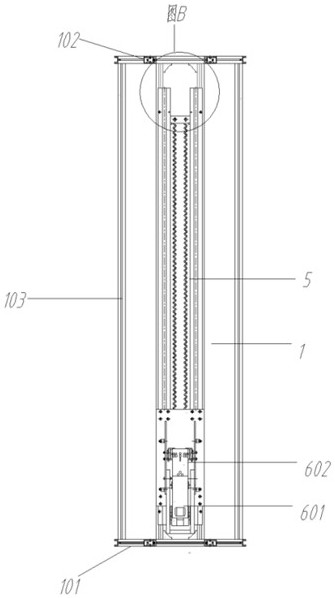

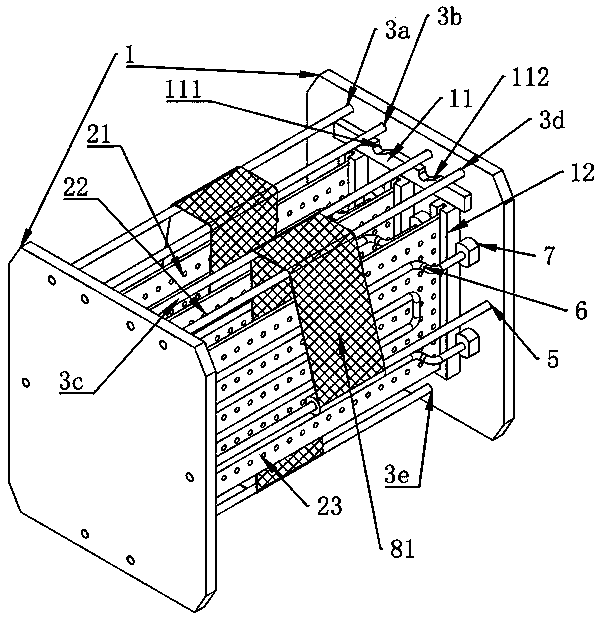

A rotating column touch type bicycle parking device

The invention discloses a rotating column touch-type bicycle parking device. The scheme adopts a hexagonal column-shaped basic frame as a column, and each column surface is provided with a bicycle lifting device, with a rain-proof awning on the top, and a bottom fixed on a disc rotating device. . When parking, the bicycle is placed upright along the hexagonal prism-shaped basic frame, and the spring when the bicycle is lifted upwards is powered to select the tension state, and the linkage clamping and lifting are triggered by the tire touch switch, and the outer rotating table at the bottom rolls and rotates around the inner rotating table. Realize bicycle access transposition. The designed rotating column touch-type bicycle parking device greatly improves the utilization rate of the occupied area, realizes the full utilization of small open spaces and corner parking spaces, and can be flexibly configured and used according to the actual situation, effectively solving the problem of random parking of bicycles The phenomenon fully reflects the convenience, automation and humanization of modern mechanical innovation design, and the device is energy-saving, low-cost, safe and reliable, and is relatively easy to accept for users.

Owner:EAST CHINA UNIV OF TECH

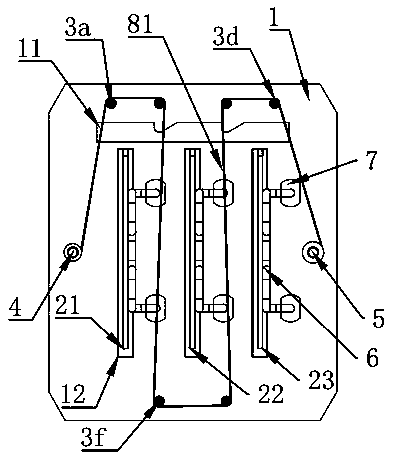

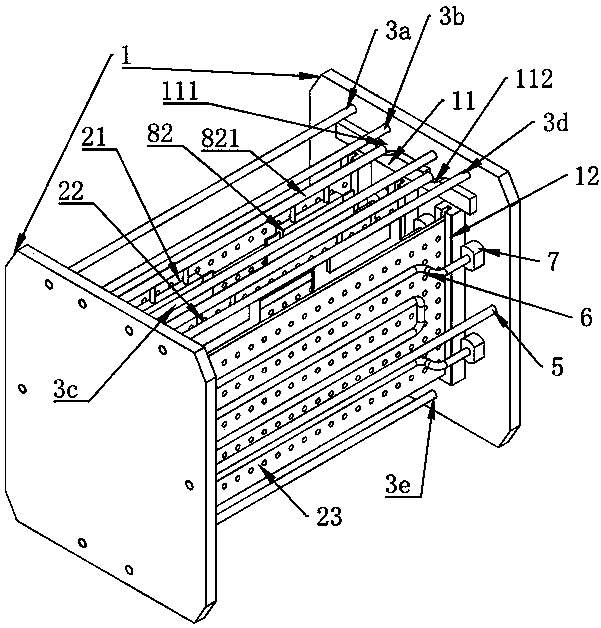

Plate-type water cooling electrode assembly plasma surface treatment device with continuous treatment function

InactiveCN104167347AHigh degree of functional integrationWide range of applicationsElectric discharge tubesPlasma surfaceElectrical and Electronics engineering

The invention discloses a plate-type water cooling electrode assembly plasma surface treatment device with the continuous treatment function. The device is structurally characterized in that the device comprises two vertical plates which are arranged in parallel and spaced for a distance, and a plurality of electrode plates which are perpendicularly arranged between the two vertical plates and grouped in parallel, the vertical plates are fixedly connected with clamp plates and a plurality of sets of insulating plates with the number equal to that of the electrode plates, the edges of the two sides of each electrode plate are positioned on the corresponding insulating plates in an inserting connection mode, the upper side and the lower side of the position, opposite to the electrode plates, of the vertical plates in the longitudinal direction are provided with guide rollers, the two sides of the position, opposite to the electrode plate sets, of the vertical plates in the vertical direction are provided with an unwinding roller and a winding roller respectively, a supporting path for coiled material pulse forms to pass by the electrode plate sets is formed by the unwinding roller, the guide rollers and the winding roller, and the clamp plates are provided with embedding grooves corresponding to positions between the electrode plates and used for positioning of plates. When the surface treatment device is applied, free switching can be carried out between coiled material treatment and plate treatment, the device is wide in application range, application flexibility of the device is broadened, use efficiency is high, resources are saved, and production cost is reduced.

Owner:SUZHOU INST OF INDAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com