Programming method of forging process

A programming method and process technology, applied in the field of forging presses, can solve the problems of not being able to adapt to new processes and later upgrades, high technical level requirements, and inflexible use, etc., so as to facilitate PLC program maintenance and upgrades, reduce Programming technical requirements, the effect of convenient storage and recall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

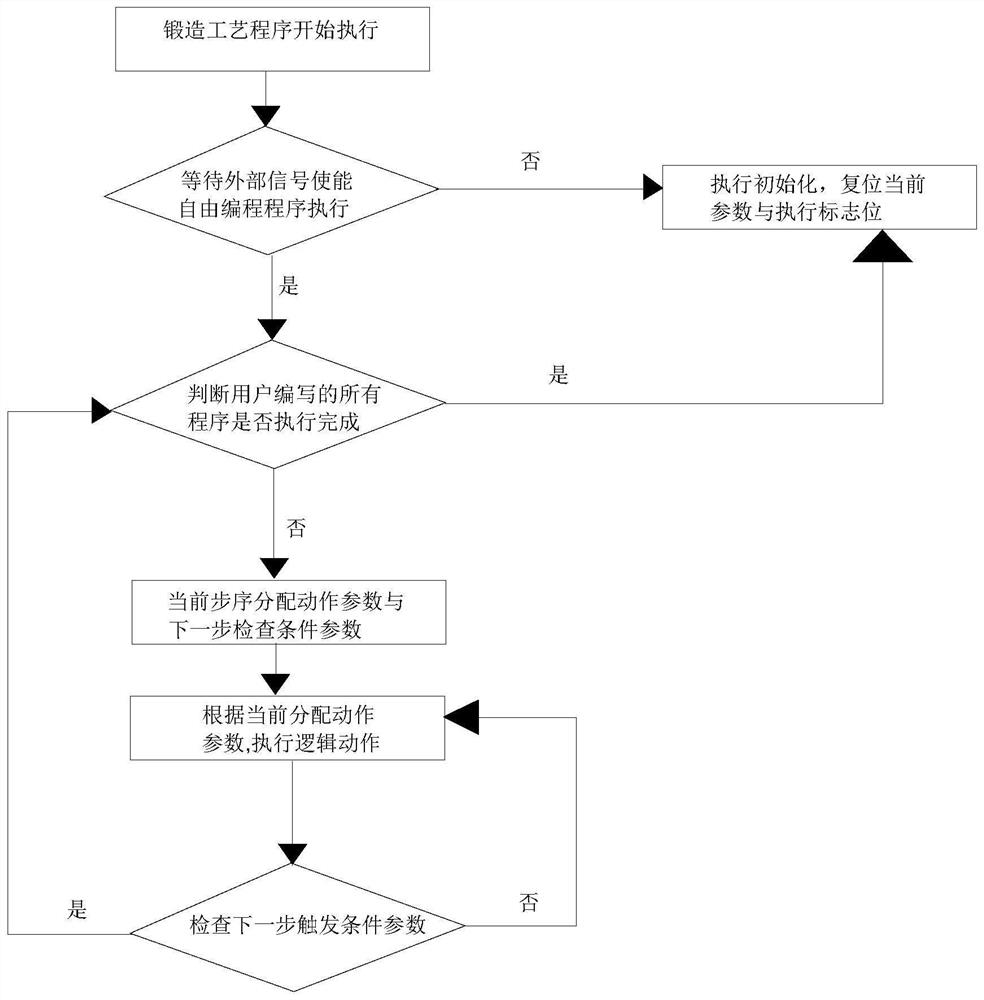

[0028] see Figure 1 to Figure 3 , a programming method for forging process,

[0029] It is completed based on the following hardware: HMI (industrial computer or touch screen), PLC (programmable logic controller), heavy forging hydraulic press.

[0030] The specific steps are:

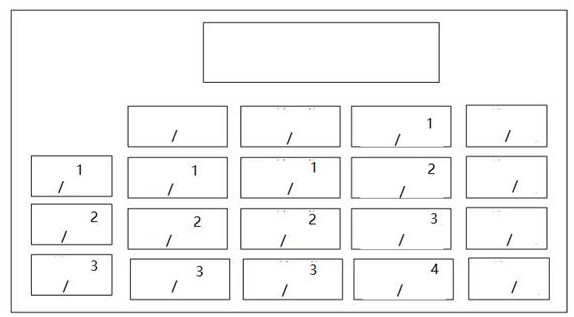

[0031] (1) The prime minister is divided into different object units and actions according to the functions of the forging press, such as figure 1 shown;

[0032] (2) In the PLC, according to the objects and actions divided by the diagram, complete the object modular programming;

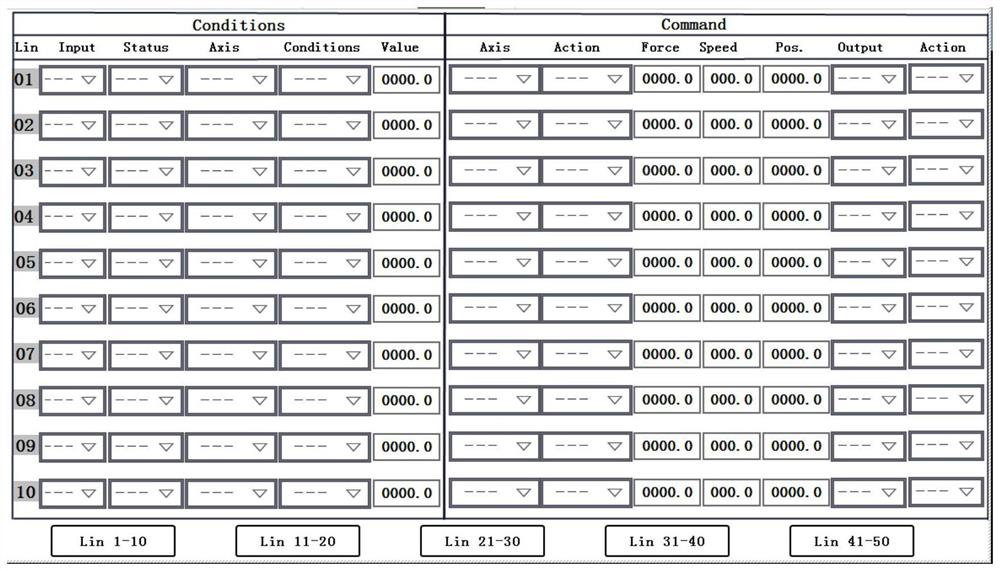

[0033] (3) Design the HMI interface, and display the modular object parameters and action images in the PLC on the HMI, such as figure 2 shown;

[0034] (4) According to the forging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com